Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Belt Scraper Innovations for Enhanced Conveyor System Efficiency and Maintenance

The Importance of Belt Scrapers in Material Handling Systems

In the world of material handling, efficiency and reliability are crucial factors that can significantly impact operational success. Belt scrapers, an often-overlooked component of conveyor systems, play a pivotal role in ensuring that these systems function effectively. This article delves into the importance, types, operational principles, and maintenance of belt scrapers, shedding light on why they are essential in optimizing conveyor performance.

Understanding Belt Scrapers

Belt scrapers are devices installed on the discharge side of a conveyor belt. Their primary function is to remove residual material that adheres to the belt after it has transported goods. Without belt scrapers, material buildup can lead to several issues, including reduced carrying capacity, increased wear on the belt, and contamination of products being handled.

The malfunctions caused by debris on the belt can result in operational inefficiencies, leading to downtime and potentially expensive repairs. Additionally, unclean surfaces can contaminate products, posing risks in industries such as food production, pharmaceuticals, and mining, where cleanliness and hygiene are paramount.

Types of Belt Scrapers

Belt scrapers come in various designs and materials, each tailored for specific applications. The two primary types of scrapers are primary and secondary scrapers.

- Primary Scrapers These are the first line of defense in removing material from the belt. They are typically made of robust materials such as polyurethane or rubber, allowing them to withstand the rigors of heavy-duty applications. Primary scrapers are adjustable and can be fitted with multiple blades to cater to different belt sizes and configurations.

- Secondary Scrapers These are used after the primary scraper to ensure a cleaner surface. Secondary scrapers often have more precise designs and are made from softer materials that conform to the belt's surface. This helps to capture any remaining material particles that the primary scraper might have missed.

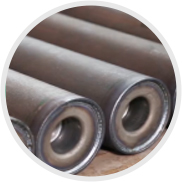

belt scraper

It’s essential to choose the correct type of scraper and ensure it is properly installed and maintained to maximize its effectiveness.

Operational Principles

Belt scrapers operate by making contact with the conveyor belt as it moves, using various mechanical principles to dislodge and remove adhering material. The effectiveness of a scraper is determined by several factors, including the angle of attack, the pressure applied to the belt, and the material composition of the scraper itself.

Adjustable features of scrapers allow operators to fine-tune their settings according to the characteristics of the material being handled and the conditions of the environment. For example, in environments where wet or sticky materials are conveyed, scrapers may need to be adjusted to apply more force or to incorporate additional blades to prevent buildup effectively.

Maintenance and Best Practices

Regular maintenance of belt scrapers is critical to ensuring their longevity and effectiveness. Operators should routinely inspect the scrapers for wear and tear, ensuring that blades are replaced as necessary. Proper alignment is also vital; a misaligned scraper can lead to increased wear on the belt and reduced cleaning efficiency.

Incorporating training programs for maintenance personnel on the importance of scrapers and their impact on material handling systems can enhance operational efficiency. This knowledge ensures that any changes in operational parameters are met with prompt adjustments to the scrapers.

Conclusion

In summary, belt scrapers are integral components in material handling systems that ensure operational efficiency, product integrity, and the longevity of conveyor belts. By understanding their types, operational principles, and necessary maintenance practices, industries can significantly optimize their material handling processes. Investing in quality belt scrapers and adhering to best practices will lead to smoother operations, less downtime, and improved overall productivity. As the industry continues to evolve, the role of belt scrapers will remain essential in supporting the ever-increasing demand for efficient material handling solutions.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025