Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 12, 2025 19:05

Back to list

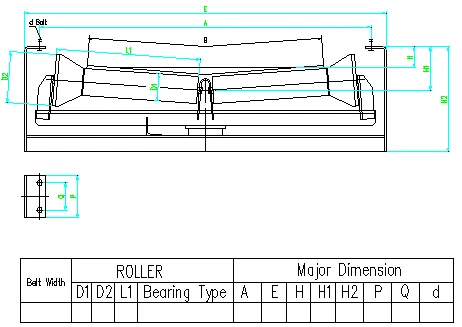

belt guide rollers

Belt guide rollers play an essential role in various industrial applications, ensuring the smooth and efficient operation of conveyor systems. These components, often overlooked, are crucial for maintaining alignment and reducing operational downtimes, thereby enhancing productivity and system longevity. Here, we delve into the key factors that make the belt guide rollers indispensable, backed by professional insights and a wealth of experience in optimizing conveyor systems.

Moreover, insight from years of application-specific experience tells us that customized solutions frequently outperform generic alternatives. Tailoring rollers to the precise requirements of a given system can involve specific adjustments to roller diameter, material choice, and shaft dimensions, all pivotal in optimizing performance. This emphasis on bespoke engineering solutions builds trust among clients who wish to see tangible efficiency improvements. In conveying systems, the seamless operation is a testament to the reliability of its components. Belt guide rollers that incorporate advanced seal technology prevent contaminants from compromising roller integrity. In dusty or wet environments, this feature is essential and renders such rollers a trustworthy component within any well-oiled industrial operation. Clients continue to seek products that promise low maintenance and high reliability — qualities that come from well-designed guide rollers. Finally, a significant aspect of trustworthiness in belt guide rollers stems from the brand and the after-sales support behind them. Customers value responsiveness and expertise in troubleshooting — attributes that come from a strong support system. Industry leaders set themselves apart by offering comprehensive guidance on installation, operational advice, and a solid warranty framework to underscore product dependability. In conclusion, belt guide rollers, although a component of conveyor systems, are indispensable due to their role in reducing maintenance costs, increasing reliability, and enhancing overall system efficiency. Leveraging industry authority, material expertise, and offering engineered solutions underpinned by professional trust, these components ensure a competitive edge. Trust in these solutions is further solidified by robust after-sales service and a commitment to excellence in inspection and compliance with global standards. These factors combined are what elevate belt guide rollers from simple components to cornerstone elements within the conveyor systems that power industries worldwide.

Moreover, insight from years of application-specific experience tells us that customized solutions frequently outperform generic alternatives. Tailoring rollers to the precise requirements of a given system can involve specific adjustments to roller diameter, material choice, and shaft dimensions, all pivotal in optimizing performance. This emphasis on bespoke engineering solutions builds trust among clients who wish to see tangible efficiency improvements. In conveying systems, the seamless operation is a testament to the reliability of its components. Belt guide rollers that incorporate advanced seal technology prevent contaminants from compromising roller integrity. In dusty or wet environments, this feature is essential and renders such rollers a trustworthy component within any well-oiled industrial operation. Clients continue to seek products that promise low maintenance and high reliability — qualities that come from well-designed guide rollers. Finally, a significant aspect of trustworthiness in belt guide rollers stems from the brand and the after-sales support behind them. Customers value responsiveness and expertise in troubleshooting — attributes that come from a strong support system. Industry leaders set themselves apart by offering comprehensive guidance on installation, operational advice, and a solid warranty framework to underscore product dependability. In conclusion, belt guide rollers, although a component of conveyor systems, are indispensable due to their role in reducing maintenance costs, increasing reliability, and enhancing overall system efficiency. Leveraging industry authority, material expertise, and offering engineered solutions underpinned by professional trust, these components ensure a competitive edge. Trust in these solutions is further solidified by robust after-sales service and a commitment to excellence in inspection and compliance with global standards. These factors combined are what elevate belt guide rollers from simple components to cornerstone elements within the conveyor systems that power industries worldwide.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS