Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Types of Belt Drive Pulleys and Their Applications in Mechanical Systems

Understanding Belt Drive Pulley Types A Comprehensive Guide

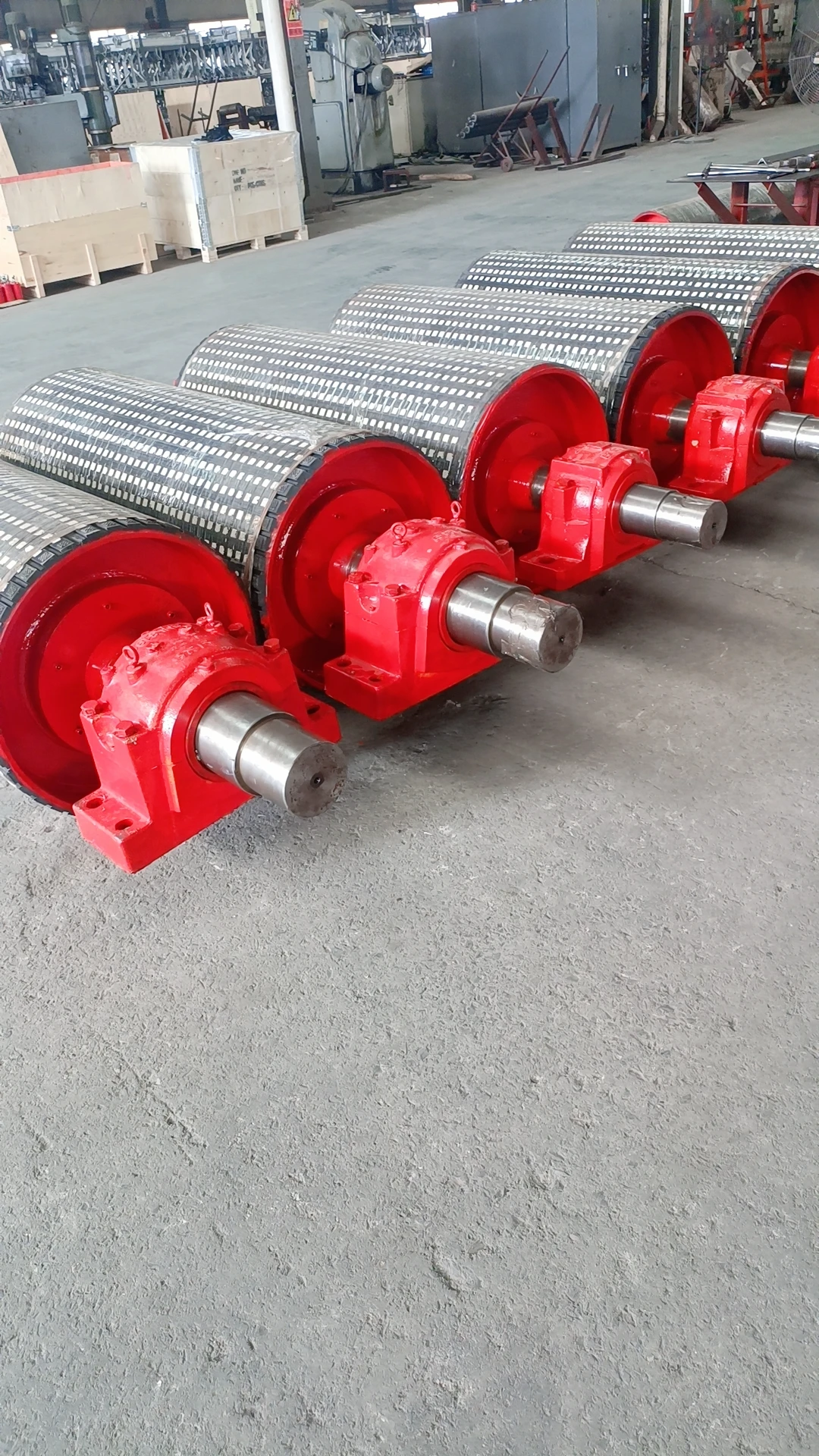

Belt drive systems are essential components in various machinery and mechanical applications. They are widely used for transferring power from one part of a machine to another, effectively increasing efficiency and enabling complex functionality. Central to these systems are pulleys, which come in several types, each designed for specific applications and types of belt drives. In this article, we will explore the various types of belt drive pulleys and their characteristics.

1. Flat Pulleys

Flat pulleys are the simplest form of pulleys used in belt drive systems. They feature a flat surface that the belt lies against. They are most commonly used in applications where belts are moved on a flat surface rather than in a groove. Flat pulleys are often found in light-duty applications, such as small machines and industrial fans, due to their straightforward design. However, they can suffer from slippage if the belt tension is not properly maintained.

2. V-Belt Pulleys

V-belt pulleys are characterized by a V-shaped groove that securely houses a V-belt. This design provides better grip and reduces the chances of slippage compared to flat pulleys. V-belt pulleys are widely used in automotive applications, industrial machines, and HVAC systems. They are available in different sizes and configurations to accommodate a range of power requirements. The efficiency and effectiveness of V-belt systems make them a popular choice for many mechanical applications.

Timing pulleys are specifically designed to work with timing belts, which feature teeth that fit into corresponding grooves on the pulley. This design allows for precise synchronization of rotational movement, making timing pulleys ideal for applications where timing accuracy is critical, such as in robotics, conveyors, and engines. They significantly reduce the chances of slippage, ensuring that the driven components maintain their correct timing.

4. Idler Pulleys

belt drive pulley types

Idler pulleys do not serve as the primary power transmission unit. Instead, they act to guide and tension the belt within a system. Idler pulleys help to improve belt alignment and can also provide additional support in high-tension applications. They are commonly found in various machinery, including conveyor systems and automotive engines. The use of idler pulleys can reduce wear and extend the lifespan of both the belt and the primary driving pulleys.

5. Multiple Groove Pulleys

Multiple groove pulleys have two or more grooves designed to accommodate multiple belts simultaneously. This type of pulley is used in applications that require the transfer of power to several systems at once, such as in larger industrial machines or heavy agricultural equipment. Multiple groove pulleys can optimize space and ensure balanced load distribution among belts, which can enhance system efficiency and performance.

6. Sheave Pulleys

Sheave pulleys are specifically designed for use with rope or cable rather than traditional belts. They often play a vital role in lifting systems, cranes, and block-and-tackle setups. Sheave pulleys can be single or multi-sheave, allowing for various mechanical advantages. Their design focuses on minimizing friction and maximizing the efficiency of the lifting process.

7. Custom Pulleys

In addition to the standard types mentioned above, custom pulleys can be designed to meet specific requirements or applications. This might involve alterations in size, material, or configuration to best fit the unique needs of a particular machinery setup. Custom pulleys ensure that businesses can optimize their operations by addressing specific challenges within their processes.

Conclusion

Understanding the different types of belt drive pulleys is essential for anyone involved in machinery design, maintenance, or operation. Each type of pulley offers unique advantages and applications, allowing for the efficient transfer of power in numerous settings. By choosing the right pulley for a specific application, companies can enhance performance, reduce downtime, and extend the lifespan of their equipment. Whether it’s flat pulleys for simple mechanical systems or timing pulleys for precision applications, selecting the correct belt drive pulley is crucial for optimal operational efficiency.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025