Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu belt drive pulley types

Understanding Belt Drive Pulley Types

Belt drive systems are crucial components in various machinery and industrial applications, facilitating the transfer of power between rotating shafts. At the heart of these systems are pulleys, which play a vital role in determining the efficiency and performance of the belt drive. In this article, we will explore different types of belt drive pulleys, their applications, and how to select the right type for your needs.

1. Basic Types of Belt Drive Pulleys

Belt drive pulleys can be classified into several types based on their design and function. The most common types include

- Fixed Pulleys These pulleys have a stationary position and are used to change the direction of force without altering the speed or torque. Fixed pulleys are primarily used in simple systems, allowing for easier lifting of loads by virtue of redirected force.

- Movable Pulleys Unlike fixed pulleys, movable pulleys can change position along with the load. They effectively reduce the amount of force needed to lift an object. By using a movable pulley, one can gain a mechanical advantage, making it easier to lift heavier loads.

- Compound Pulleys These consist of a combination of fixed and movable pulleys, forming a block-and-tackle system. Compound pulleys provide significant mechanical advantage and are commonly used in applications requiring the lifting of heavy weights with less effort.

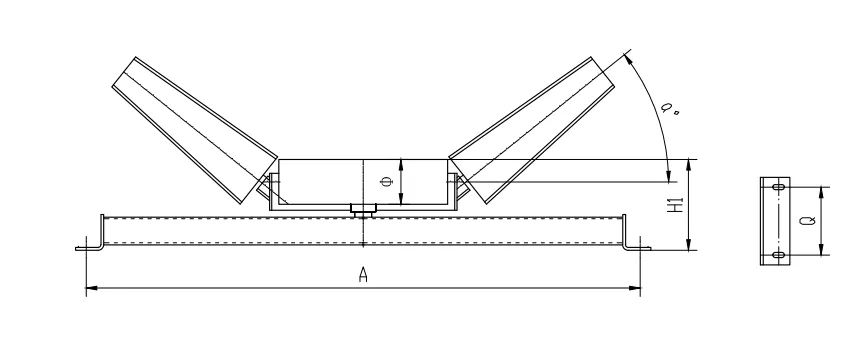

- Idler Pulleys Idler pulleys are not directly involved in lifting but are essential for guiding and maintaining proper tension on the belt. They help prevent belt slippage and undue wear, thereby extending the lifespan of the belt drive system.

2. Material Considerations

The materials used to manufacture belt drive pulleys significantly influence their performance and durability. Common materials include

- Steel Known for its strength and durability, steel pulleys are often used in heavy-duty applications. They can withstand high loads and offer excellent wear resistance.

- Aluminum Lightweight and resistant to corrosion, aluminum pulleys are favored in applications where weight is a concern. While they may not handle as much load as steel, they are suitable for smaller, less demanding tasks.

- Plastic Plastic pulleys are used in lighter applications where cost efficiency and weight reduction are primary concerns. They are suitable for low-load situations but may not provide the durability needed in industrial contexts.

3. Performance Factors

belt drive pulley types

When selecting a belt drive pulley system, several performance factors need to be considered

- Diameter The diameter of the pulley affects the mechanical advantage and speed of rotation. A larger pulley diameter can provide more torque but may slow down the speed of the shaft it drives.

- Belt Type Different belt types, such as V-belts and flat belts, interact differently with pulleys. Selecting the right pulley design is crucial for optimal performance with your specific belt type.

- Load Capacity Each pulley has a specific load-bearing capacity. It's essential to ensure that the chosen pulley can handle the operational loads without risk of failure.

- Speed The rotational speed of the pulley is also paramount. Higher speeds may require pulleys with specific designs to minimize vibration and maintain balance.

4. Applications

Belt drive pulleys are found in a wide range of applications across various industries

- Manufacturing Used in conveyor systems, milling machines, and other machinery for material handling and processing.

- Automotive Essential in engine systems for driving components like the alternator and water pump.

- Agriculture Utilized in various farming equipment, including tractors and harvesters, to drive machinery efficiently.

- Construction Pulleys are used in cranes and hoists to facilitate lifting and lowering heavy materials.

Conclusion

Understanding the types and functions of belt drive pulleys is essential for anyone involved in mechanical design, maintenance, or repair. By recognizing the various types of pulleys available and their specific applications, you can make informed decisions that enhance the efficiency and reliability of your belt drive systems. Whether you're working in manufacturing, automotive, or agriculture, the right pulley choice can make all the difference in achieving optimal performance and longevity of your equipment.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025