Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Understanding the Mechanics of Belt Drive Systems and Their Applications in Industry

Understanding Belt Drive Pulleys A Comprehensive Guide

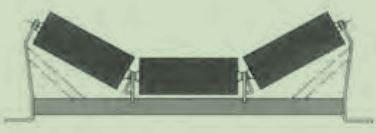

Belt drive pulleys are integral components in various mechanical systems, serving a critical function in the transmission of power and motion. These devices utilize belts, typically made from rubber or other flexible materials, to connect pulleys and transfer energy from one part of a machine to another. In this article, we will explore the construction, operation, advantages, and applications of belt drive pulleys.

Construction of Belt Drive Pulleys

Belt drive pulleys consist of several key components that facilitate their operation. Typically made from metal, plastic, or other durable materials, pulleys can vary in size and design. The main elements include the pulley body, which is usually circular, and a groove or channel that circumferences the outer edge. This groove is designed to accommodate the belt securely.

Pulleys are categorized into two primary types driver pulleys and driven pulleys. The driver pulley is connected to the power source, such as an electric motor, while the driven pulley is connected to the load. The effective transfer of power between these two components is facilitated by the belt running through the grooves.

How Belt Drive Pulleys Operate

The operating principle of belt drive pulleys is relatively straightforward. When the driver pulley rotates, it causes the belt to move along its surface. This movement, in turn, drives the driven pulley, resulting in the desired mechanical movement or application. The efficiency of this system is influenced by several factors including belt tension, friction between the belt and pulleys, and the alignment of the pulleys.

One of the unique features of belt drive systems is their ability to allow for variable speed ratios. By altering the size ratio between the driver and driven pulleys, engineers can achieve different speeds and torque outputs. For instance, a smaller driver pulley linked to a larger driven pulley will increase torque while reducing speed, which can be beneficial in specific applications such as machinery that requires high force.

Advantages of Belt Drive Pulleys

belt drive pulley

Belt drive pulleys offer various advantages that make them popular in many industrial applications. One of the standout benefits is their ability to dampen vibration, leading to quieter operation compared to gear-based systems. This makes them ideal for use in environments where noise must be minimized.

Another significant advantage is the flexibility they offer in terms of design. Belt drive systems can be easily configured to transmit power over a distance, allowing for the separation of power sources and machinery. Additionally, belts are generally easier and cheaper to replace than gears or chains, which translates to lower maintenance costs.

Belt drive pulleys also exhibit a high degree of efficiency, with many systems achieving over 90% efficiency. This makes them suitable for use in both light-duty and heavy-duty applications, extending their versatility across different industries.

Applications of Belt Drive Pulleys

The applications for belt drive pulleys are vast and varied. They are commonly found in automotive systems, where they transmit power from the engine to various components such as alternators, water pumps, and air conditioning compressors. In manufacturing and industrial settings, belt drives are utilized in conveyor systems, lathes, and milling machines, showcasing their essential role in driving production processes.

Moreover, in the consumer domain, belt drive systems are present in numerous household appliances, from washing machines to vacuum cleaners, demonstrating their indispensable nature in everyday life.

Conclusion

Belt drive pulleys are not just mechanical components; they represent a blend of engineering innovation and practical application. The efficiency, versatility, and cost-effectiveness of belt drive systems make them an attractive choice for both industrial and commercial applications. Understanding how these systems work and their advantages can help individuals and businesses make informed decisions regarding their use in various mechanical setups. As technology continues to advance, belt drive pulleys will likely evolve further, maintaining their essential role in the machinery that powers our world.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025