Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

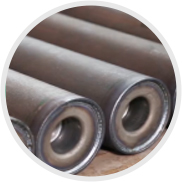

Zulu belt drive idler pulley

Understanding Belt Drive Idler Pulleys

Belt drive systems are integral components in numerous mechanical devices that rely on belts to transmit power from one point to another. In these systems, idler pulleys play a crucial role in enhancing the performance and efficiency of belt drives. This article delves into the significance, function, and types of belt drive idler pulleys.

What is an Idler Pulley?

An idler pulley is a wheel or pulley that does not drive any machinery directly but serves to guide, tension, or route a belt. Idler pulleys are essential in maintaining proper belt alignment and providing tension in belt systems, which directly influences the performance and longevity of both the belt and the associated machinery.

The Significance of Idler Pulleys

The main purpose of an idler pulley is to maintain tension in the belt. A properly tensioned belt reduces slippage, which can lead to increased wear, energy loss, and potential system failure. By ensuring optimal tension, idler pulleys help in maximizing the efficiency of the power transmission system.

Moreover, idler pulleys contribute to the overall compactness of belt drive designs. They allow for more flexible routing of belts, enabling engineers to design more space-efficient arrangements, which is particularly valuable in constrained spaces where machinery is housed.

How Idler Pulleys Work

The operation of an idler pulley is straightforward. When the belt is looped around the idler pulley, it creates tension. This tension causes the belt to conform tightly to the pulleys it engages, ensuring effective energy transfer. Ideally, when the system is functioning, belts should maintain a consistent tension which is vital for their efficiency and longevity.

In practical applications, if any misalignment or sag occurs, the idler pulley can be adjusted or replaced to restore proper tension. This adjustability aspect is crucial because belts can stretch or undergo wear over time, necessitating regular maintenance to avoid failures.

Types of Idler Pulleys

belt drive idler pulley

Idler pulleys come in various types, each tailored for specific applications. Some common types include

1. Fixed Idler Pulleys These are stationary and provide simple guidance and tensioning for the belt.

2. Adjustable Idler Pulleys These pulleys can be repositioned to alter belt tension or alignment, making them versatile for different applications.

3. Spring-loaded Idler Pulleys Utilizing a spring mechanism, these pulleys automatically adjust tension according to the belt's needs, thus accommodating variations in load and wear.

4. Guiding Idler Pulleys Primarily used for routing belts, these pulleys help maintain the correct path of the belt through the system.

Applications of Idler Pulleys

Idler pulleys are commonly found in various applications, from automotive engines to industrial machinery and even in household appliances. They are particularly prevalent in systems where the belt requires routing around more than two pulleys or where tension must be adjusted frequently.

In automotive applications, for example, idler pulleys help in routing serpentine belts that power multiple engine accessories, ensuring that each component receives the power required for efficient operation. Similarly, in manufacturing lines, idler pulleys facilitate the movement of conveyor belts, ensuring smooth and consistent operation.

Conclusion

In summary, belt drive idler pulleys are vital components that significantly impact the efficiency and functionality of various mechanical systems. By maintaining proper belt tension and alignment, they enhance performance, reduce wear, and prolong the life of the belts and associated machinery. Understanding their function and types is essential for anyone involved in the design, maintenance, or operation of belt-driven systems, making idler pulleys integral to mechanical engineering.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025