Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Mar . 04, 2025 02:19

Back to list

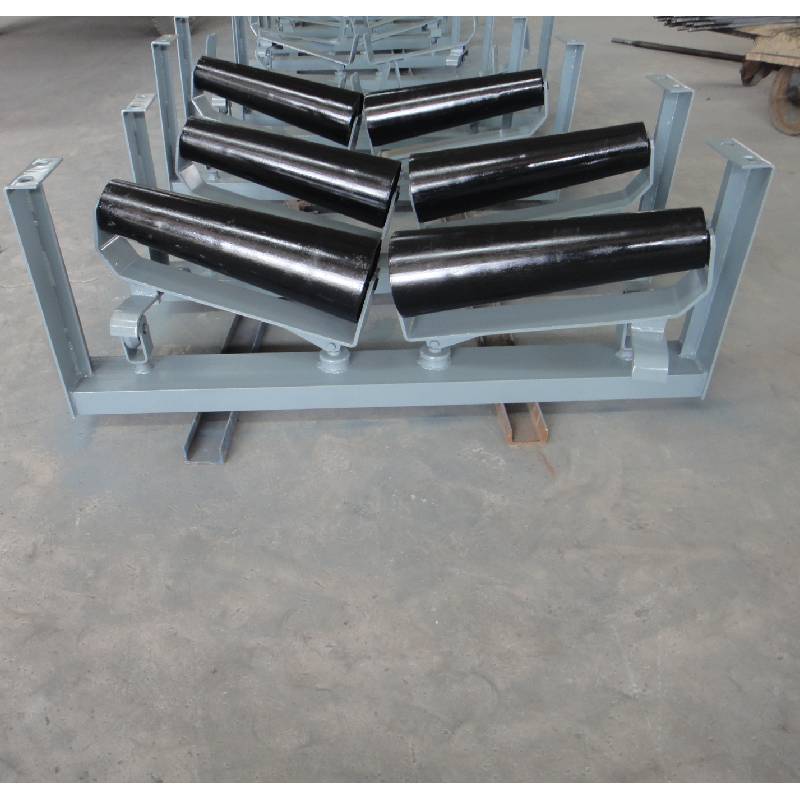

belt drive idler

For engineers and manufacturers seeking efficient power transmission systems, belt drive idlers play a crucial role in ensuring smooth machinery operation. As a critical component, these idlers provide tension and guide belts in various industrial applications ranging from automotive to agricultural machinery. This article delves into the significance of belt drive idlers and provides expert insights into their selection, installation, and maintenance.

The installation process for belt drive idlers demands precision and attention to detail. Correct alignment is critical to prevent premature belt wear. Misalignment can lead to increased friction, overheating, and eventual system failure. Therefore, utilizing proper alignment tools and techniques is vital for successful installation. Regularly using a straight edge or laser alignment tools can ensure that the idler maintains the correct position over time. Maintaining belt drive idlers involves regular inspection and timely interventions. Belt tension should be checked periodically, as inadequate tension can lead to slippage, while excessive tension might cause undue stress on both the idler and the belt. Lubrication, where applicable, helps reduce friction and wear, significantly increasing the life span of the idler. In environments with high contamination, such as dusty or moist settings, seals and shields may be necessary to protect the idler bearings from debris and moisture ingress. Trustworthiness in the realm of belt drive idler systems is built upon delivering consistent performance and reliability. Manufacturers and engineers must collaborate closely to ensure that idlers meet the required specifications and industry standards. Using genuine parts and adhering to manufacturer guidelines can help maintain credibility and enhance the performance of machinery. In summary, belt drive idlers are small yet powerful components that can significantly influence the reliability and efficiency of power transmission systems. By understanding the importance of correct selection, installation, and maintenance, professionals in mechanical and manufacturing industries can optimize their machinery's performance, extending its service life and ensuring seamless operation. As technology and industrial demands evolve, staying informed about the latest advancements in idler design and materials will be key to maintaining a competitive edge in the industry.

The installation process for belt drive idlers demands precision and attention to detail. Correct alignment is critical to prevent premature belt wear. Misalignment can lead to increased friction, overheating, and eventual system failure. Therefore, utilizing proper alignment tools and techniques is vital for successful installation. Regularly using a straight edge or laser alignment tools can ensure that the idler maintains the correct position over time. Maintaining belt drive idlers involves regular inspection and timely interventions. Belt tension should be checked periodically, as inadequate tension can lead to slippage, while excessive tension might cause undue stress on both the idler and the belt. Lubrication, where applicable, helps reduce friction and wear, significantly increasing the life span of the idler. In environments with high contamination, such as dusty or moist settings, seals and shields may be necessary to protect the idler bearings from debris and moisture ingress. Trustworthiness in the realm of belt drive idler systems is built upon delivering consistent performance and reliability. Manufacturers and engineers must collaborate closely to ensure that idlers meet the required specifications and industry standards. Using genuine parts and adhering to manufacturer guidelines can help maintain credibility and enhance the performance of machinery. In summary, belt drive idlers are small yet powerful components that can significantly influence the reliability and efficiency of power transmission systems. By understanding the importance of correct selection, installation, and maintenance, professionals in mechanical and manufacturing industries can optimize their machinery's performance, extending its service life and ensuring seamless operation. As technology and industrial demands evolve, staying informed about the latest advancements in idler design and materials will be key to maintaining a competitive edge in the industry.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS