Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu belt drive idler

Understanding Belt Drive Idlers A Key Component in Mechanical Systems

In various mechanical systems, the efficiency and reliability of power transmission are paramount. One of the critical components that ensure smooth operation in belt-driven systems is the belt drive idler. This seemingly simple component plays a significant role in enhancing the performance and durability of the entire setup.

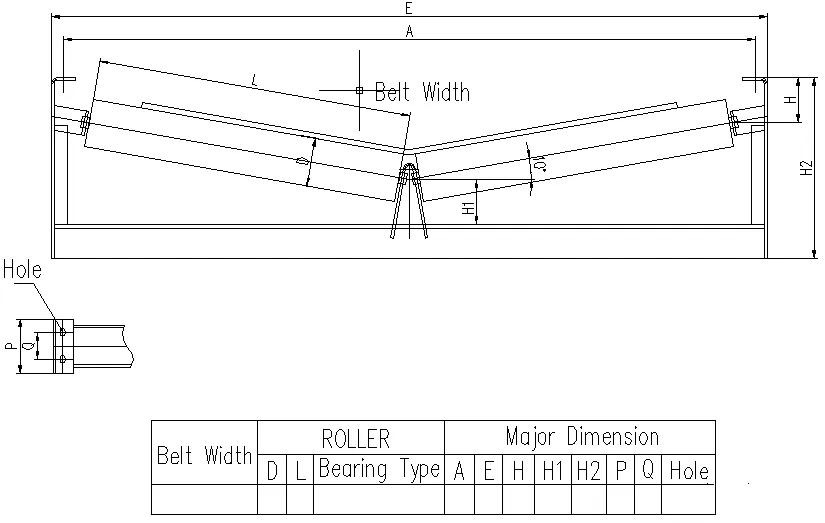

A belt drive system typically consists of a belt, pulleys, and idlers. The belt transmits power from a driving pulley to a driven pulley. However, aligning these components perfectly is essential for effective operation. This is where the idler comes into play. An idler is a pulley that does not receive power but serves to guide the belt and maintain proper tension across the system. By doing so, it helps prevent slippage and reduces the wear and tear on the belt.

One of the primary functions of the belt drive idler is to adjust the length of the belt’s path. In some applications, the distance between the drive and driven pulleys can change slightly due to variations in load or positioning. An idler can help mitigate these changes by adjusting the belt's tension, maintaining optimal contact between the belt and pulleys. This adjustment not only ensures reliable power transmission but also extends the lifespan of the belt.

belt drive idler

Moreover, idlers can assist in changing the direction of the belt. In complex machinery where space is constrained, idlers can redirect the belt's path, allowing for more versatile designs. This flexibility is crucial in modern engineering applications, where maximizing space and efficiency are often at odds.

The materials used for idlers also critically impact their performance. They must be durable enough to withstand operational stresses while also being lightweight to minimize inertia. Common materials include various metals and engineered plastics that offer both strength and reduced friction, further enhancing the efficiency of the belt drive system.

Maintenance is another essential aspect to consider. Regular inspection of idlers is necessary to ensure they are functioning correctly. Over time, idlers may wear out or become misaligned, leading to potential issues such as increased noise, reduced efficiency, or complete system failure. Keeping idlers in optimal condition can prevent costly repairs and downtime.

In conclusion, belt drive idlers may be small, but their impact on mechanical systems is substantial. By improving tension, redirecting belts, and ultimately enhancing the overall reliability and efficiency of the system, idlers are a key component in various applications, from automotive systems to industrial machinery. As technology continues to evolve, the design and engineering of belt drive idlers will play an essential role in the advancement of mechanical systems, driving innovation and efficiency in the field. Understanding the significance of these components can lead to more effective designs and implementations across various industries.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025