Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Top Suppliers of Belt Conveyor Rollers for Efficient Material Handling Solutions

The Importance of Belt Conveyor Roller Suppliers in Modern Industry

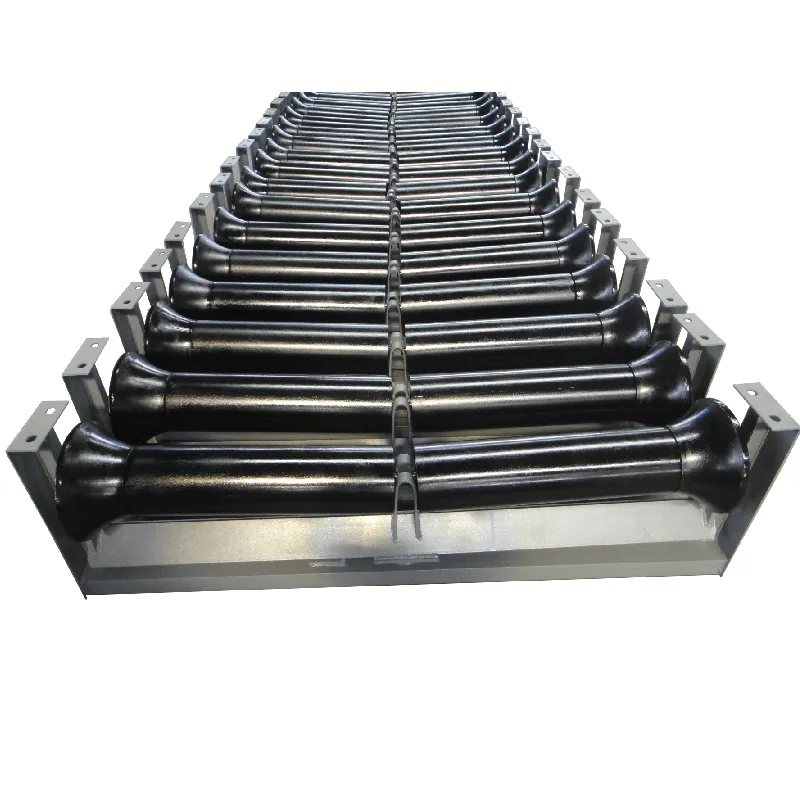

Belt conveyors are an integral part of many industries, from manufacturing and mining to logistics and food processing. Among the various components that make these systems effective, conveyor rollers play a crucial role. They not only support the belt but also facilitate its movement, ensuring that the materials are transported efficiently. As such, the choice of conveyor roller suppliers becomes paramount for businesses looking to enhance their operations.

The Role of Conveyor Rollers

Conveyor rollers serve multiple functions in a belt conveyor system. They minimize friction between the belt and the surface it runs on, which is essential for reducing wear and tear on both the belt and the motor. By ensuring the belt runs smoothly, rollers help to maximize the system's efficiency, which, in turn, affects overall productivity. Additionally, high-quality rollers can significantly extend the lifespan of the conveyor system, reducing replacement and maintenance costs in the long run.

Selecting the Right Supplier

Choosing a reliable belt conveyor roller supplier is fundamental to ensuring the success of an operation. First and foremost, suppliers must provide high-quality rollers that can withstand extreme conditions. For instance, in industries like mining, rollers may have to endure heavy loads, abrasive materials, and challenging environments. Suppliers should offer a variety of rollers designed for different applications, including standard, heavy-duty, and specialty rollers.

Moreover, it is crucial for suppliers to be equipped with the knowledge and expertise to advise businesses on the best roller options for their specific needs. Expert guidance can help in selecting rollers that optimize the performance of conveyor systems, leading to increased efficiency and cost savings.

Innovation and Technology

belt conveyor roller suppliers

The conveyor roller market has seen significant advancements in technology and materials. Modern suppliers are now able to offer rollers made from high-performance materials that enhance durability and reduce weight, contributing to lower energy consumption. Moreover, innovative designs, such as self-aligning rollers and adjustable rollers, help optimize the conveyor system's performance.

When businesses invest in advanced rollers, they not only improve their operational efficiency but also foster sustainability by reducing energy use and prolonging equipment life. Therefore, aligning with a supplier that emphasizes innovation can have long-term benefits.

Cost Considerations

While it may be tempting to choose the cheapest supplier, this can lead to additional costs in terms of maintenance and potential system failures. A focus on quality should always take precedence. Many reputable suppliers offer warranties and post-sale support, which adds another layer of assurance for companies investing in their products.

It is wise for businesses to assess the total cost of ownership when choosing a supplier, considering not just the initial purchase price but also the projected maintenance and operational costs over time.

Conclusion

Belt conveyor roller suppliers play a vital role in the seamless operation of conveyor systems across various industries. The right supplier can provide high-quality, innovative products that enhance the efficiency and longevity of conveyor systems. As industries continue to evolve and demand higher efficiency, businesses must prioritize working with reliable suppliers who can meet their unique needs.

By making informed choices about conveyor roller suppliers, companies can optimize their operations, reduce costs, and ultimately achieve greater productivity in today's competitive marketplace. Investing in quality and expertise in this vital component can be a game-changer for many businesses in the long run.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025