Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu belt conveyor roller price

Understanding the Pricing of Belt Conveyor Rollers

Belt conveyor rollers play a critical role in the material handling industry, serving as integral components in the operation of conveyor systems. These rollers support the conveyor belt, reduce friction, and facilitate the smooth transfer of materials across various distances. Due to their significant importance, the price of belt conveyor rollers can vary widely based on a range of factors. Understanding these variables can help businesses make informed purchasing decisions.

Factors Influencing Price

1. Material Quality The construction material of the rollers has a direct impact on their cost. Rollers made from high-quality steel or specialized alloys tend to be more expensive due to their durability and resistance to wear and tear. Conversely, rollers made from lower-grade materials may be more affordable but can result in higher maintenance costs over time.

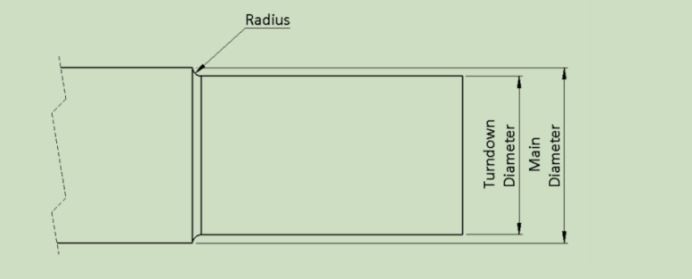

2. Size and Specifications The dimensions and specifications of the rollers, including diameter, length, and load-bearing capacity, also affect the pricing. Larger rollers or those designed for heavy-duty applications typically come with a higher price tag due to the additional materials and engineering required.

3. Type of Roller There are various types of conveyor rollers, such as plain, grooved, and crowned rollers, each serving different purposes. Specialized rollers designed for specific applications, like those used in inclined or curved conveyors, are often priced higher due to their complexity and the engineering involved in their design.

4. Manufacturing Processes The method of production can influence roller pricing as well. Rollers manufactured through advanced technologies such as precision machining or automated assembly may incur higher costs compared to those produced using traditional methods. Custom-designed rollers tailored to specific operational requirements can also drive up prices.

belt conveyor roller price

5. Volume of Purchase The quantity purchased can play a significant role in pricing. Many manufacturers offer discounts for bulk orders, making it more cost-effective for businesses to purchase larger quantities of rollers at once.

6. Brand and Reputation Established brands in the manufacturing sector often command higher prices due to their reputation for quality and reliability. Businesses may be willing to pay a premium for products from trusted manufacturers that provide warranties and excellent customer support.

Regional Variations

Pricing can also vary by region depending on factors such as shipping costs, local demand, and the availability of materials. Companies in remote locations may face higher prices due to increased transportation costs for obtaining the rollers. Additionally, economic factors such as inflation and market competition can influence pricing trends in different areas.

Conclusion

When considering the purchase of belt conveyor rollers, it is essential to evaluate the various factors that influence their pricing. While it may be tempting to choose the lowest-cost options, investing in high-quality rollers can lead to better performance and lower maintenance costs in the long run. Businesses should consider their specific needs, including the operating environment and load requirements, to select the most suitable rollers for their conveyor systems.

Ultimately, understanding the intricate dynamics of belt conveyor roller pricing can empower businesses to make wise investment decisions, optimize their operations, and ensure long-term efficiency in their material handling processes. Investing in high-quality rollers is not merely a cost but a strategic decision that can yield substantial returns over time.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025