Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu belt conveyor roller china

Belt Conveyor Roller in China A Comprehensive Overview

Belt conveyor rollers are essential components in the field of material handling and transportation. In China, the production and innovation of these rollers have gained significant momentum, contributing to various industries, including mining, agriculture, and manufacturing. This article explores the types, manufacturing processes, and the future of belt conveyor rollers in China.

Understanding Belt Conveyor Rollers

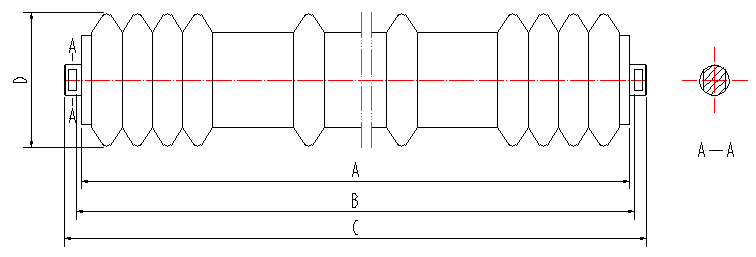

Belt conveyor rollers are cylindrical devices that support the conveyor belt. They are crucial in ensuring the efficient transfer of materials over different distances and terrains. Typically, they are designed to minimize friction and facilitate smooth movement, enhancing overall operational efficiency.

Rollers are categorized into several types based on their application and design 1. Idler Rollers These are non-driven rollers that support the belt and material load. They are crucial for maintaining belt tension and alignment. 2. Drive Rollers These are powered rollers that offer the necessary traction to move the belt and are crucial for conveying material. 3. Return Rollers Used in the return section of the conveyor belt, they help guide the belt back to its starting point.

The Manufacturing Landscape

China has become a global hub for the manufacturing of belt conveyor rollers due to its advanced industrial capabilities and technological advancements

. The country boasts numerous manufacturers that produce a variety of rollers, meeting both local and international standards.The manufacturing process of belt conveyor rollers generally involves several steps - Material Selection High-quality materials such as steel, rubber, and plastics are chosen to ensure durability and resistance to wear and tear. - Fabrication The raw materials undergo processes like cutting, welding, and machining to form the roller components. - Assembly The various parts are then assembled, which may include bearings, seals, and other components essential for the smooth functioning of the rollers. - Quality Control Rigorous testing is conducted to meet safety and performance standards, ensuring that the rollers can withstand the operational demands of different industries.

Technological Innovations

belt conveyor roller china

The advancement of technology in China has significantly impacted the design and functionality of belt conveyor rollers. Manufacturers are increasingly adopting automation and robotics in the production process, enhancing precision and reducing costs. Additionally, innovations such as self-lubricating bearings and anti-corrosion coatings are becoming standard features, increasing the lifespan and efficiency of rollers.

Moreover, the integration of smart technology in conveyor systems, including sensors and monitoring devices, is gaining traction. These advancements not only optimize the performance of belt conveyor rollers but also enable predictive maintenance, ultimately reducing downtime and operational costs.

Challenges and Environmental Considerations

While the industry is thriving, it is not without challenges. The environmental impact of roller production and the use of non-eco-friendly materials have raised concerns. In response, many Chinese manufacturers are shifting towards sustainable practices, utilizing recycled materials and adopting green manufacturing techniques.

Additionally, the fierce competition in the market necessitates continuous innovation and improvement. Companies that can adapt to changing industry demands and focus on quality will stay ahead in this rapidly evolving sector.

The Future of Belt Conveyor Rollers in China

The future for belt conveyor rollers in China appears promising. As industries evolve and demand for efficient material handling increases, the need for high-quality rollers will continue to grow. Furthermore, China's commitment to infrastructure development signals an ongoing need for reliable conveyor systems across various sectors.

In conclusion, the belt conveyor roller industry in China is a dynamic and integral part of global manufacturing. With continuous advancements in technology, a focus on sustainability, and the increasing demand across numerous industries, the future is bright for this essential component of material handling systems. As manufacturers innovate and adapt, belt conveyor rollers will undoubtedly play a crucial role in shaping the logistics and transportation landscape in the years to come.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025