Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 13, 2025 11:26

Back to list

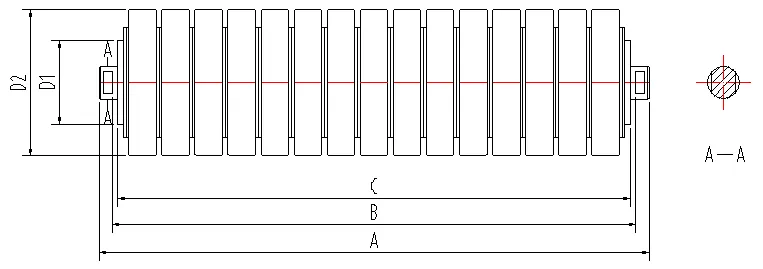

belt conveyor return roller

The belt conveyor return roller may seem like a minor component in the larger system of industrial conveyor belts, but its role is pivotal in ensuring the efficiency and longevity of conveyor operations. While many might overlook the importance of these rollers, a seasoned engineer understands that a finely tuned belt conveyor system can mean the difference between peak production and costly downtimes.

Trustworthiness is paramount in choosing the right return roller supplier. A reputable manufacturer will not only provide components but also support clients with comprehensive technical guidance and post-installation assistance. This trust is built through years of demonstrated performance, verified by user reviews and case studies that highlight successful implementations across various sectors. Moreover, experience highlights that preventative maintenance schedules must incorporate regular inspections of return rollers to check for misalignments, wear patterns, and lubrication needs. An experienced operations manager knows that proper maintenance improves the system’s lifespan, enhances productivity, and prevents unexpected halts in operation, which are often costly setbacks. In conclusion, belt conveyor return rollers, though frequently underestimated, are fundamental to the operational efficacy of conveyor systems. Their role transcends simple mechanical function by contributing significantly to energy efficiency, system reliability, and operational safety. Conveyance system specialists and manufacturers who prioritize high-quality, adaptable, and durable return rollers are instrumental in advancing industrial efficiency and sustainability.

Trustworthiness is paramount in choosing the right return roller supplier. A reputable manufacturer will not only provide components but also support clients with comprehensive technical guidance and post-installation assistance. This trust is built through years of demonstrated performance, verified by user reviews and case studies that highlight successful implementations across various sectors. Moreover, experience highlights that preventative maintenance schedules must incorporate regular inspections of return rollers to check for misalignments, wear patterns, and lubrication needs. An experienced operations manager knows that proper maintenance improves the system’s lifespan, enhances productivity, and prevents unexpected halts in operation, which are often costly setbacks. In conclusion, belt conveyor return rollers, though frequently underestimated, are fundamental to the operational efficacy of conveyor systems. Their role transcends simple mechanical function by contributing significantly to energy efficiency, system reliability, and operational safety. Conveyance system specialists and manufacturers who prioritize high-quality, adaptable, and durable return rollers are instrumental in advancing industrial efficiency and sustainability.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS