Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Components and Functions of Belt Conveyor Systems Explained in Detail

Understanding Belt Conveyor Parts and Their Functions

Belt conveyors are integral components of many industrial operations, used extensively for transporting materials across various sectors. Their efficient design has made them a standard choice in manufacturing, mining, and distribution facilities. Understanding the parts of a belt conveyor and their functions is crucial for anyone involved in the installation, maintenance, or operation of this equipment.

1. Conveyor Belt The Lining Component

At the heart of any belt conveyor system is the conveyor belt itself. This continuous loop of material is typically made from rubber, fabric, or metal, depending on the specific application and the materials being transported. The primary function of the conveyor belt is to carry the load from one end of the conveyor to the other, providing a reliable surface that minimizes friction and maximizes efficiency. The choice of belt material affects not only durability and flexibility but also the ability to handle specific types of cargos, from heavy bulk materials to lighter packaged goods.

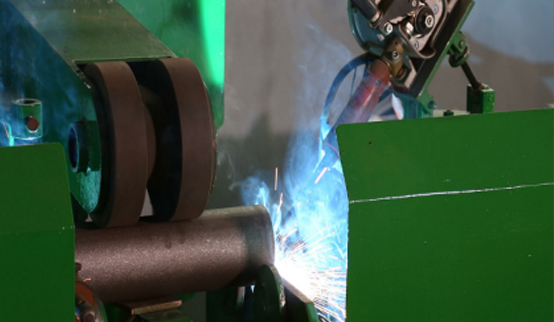

2. Drive System The Power Behind Movement

The drive system is paramount in any belt conveyor, as it provides the necessary power to move the belt and its load. This system typically consists of an electric motor, gearbox, and drive pulley. The electric motor initiates the movement, while the gearbox controls the speed and torque. The drive pulley, usually mounted at the discharge end of the conveyor, is where the belt is looped around and begins its journey back. Proper maintenance and selection of the drive system are vital to ensure continuous operation and avoid unexpected downtimes.

Idlers are rollers positioned along the length of the conveyor to support the belt and assist in material handling. They play a critical role in minimizing friction and ensuring smooth movement of the belt over its path. Idlers are often used in a troughing position to scoop materials onto the belt, increasing the system's transport capacity. Additionally, there are return idlers that support the empty belt as it returns to the drive end, helping maintain the belt's alignment and stability.

belt conveyor parts and functions

4. Pulleys Redirecting and Tensioning

Pulleys are essential components that change the direction of the conveyor belt and maintain the necessary tension. There are several types of pulleys in a belt conveyor system, including the drive pulley, tail pulley, and snub pulley. The drive pulley is responsible for propelling the belt, while the tail pulley supports the opposite end of the belt. Snub pulleys are used to change the direction of the belt or provide additional tension. Proper alignment and tension of the pulleys are crucial for optimal performance as misalignment can lead to belt wear and operational inefficiencies.

5. Belts Tensioning Devices Ensuring Belt Consistency

To maintain efficient operation, a belt conveyor requires a belt tensioning system. These devices ensure that the belt is neither too loose nor too tight, which can lead to slippage or excessive wear. Common tensioning methods include mechanical devices like screw tensioners and hydraulic systems, which provide precise control over belt tension. Regular monitoring and adjustment of belt tension are essential for extending the life of both the belt and the conveyor system.

6. Control System The Brain of the Operation

A conveyor belt system’s control system often includes a combination of sensors, controllers, and drives that facilitate automated operations. These systems can detect variations in load and adjust the speed of the conveyor accordingly. Modern conveyor systems employ advanced technologies like PLCs (Programmable Logic Controllers) and IoT (Internet of Things) for real-time monitoring and data collection, allowing for greater efficiency and predictive maintenance.

Conclusion

Belt conveyors are fundamental to modern industrial operations. Understanding the various parts—such as the conveyor belt, drive system, idlers, pulleys, tensioning devices, and control systems—and their respective functions is crucial for optimizing performance and ensuring longevity. Proper maintenance and operation of these components can reduce downtime, increase efficiency, and enhance overall productivity in material handling processes. Investing time in learning about these systems can significantly benefit anyone involved in conveyor operation or management.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025