Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu belt conveyor idler design

Belt Conveyor Idler Design An Overview

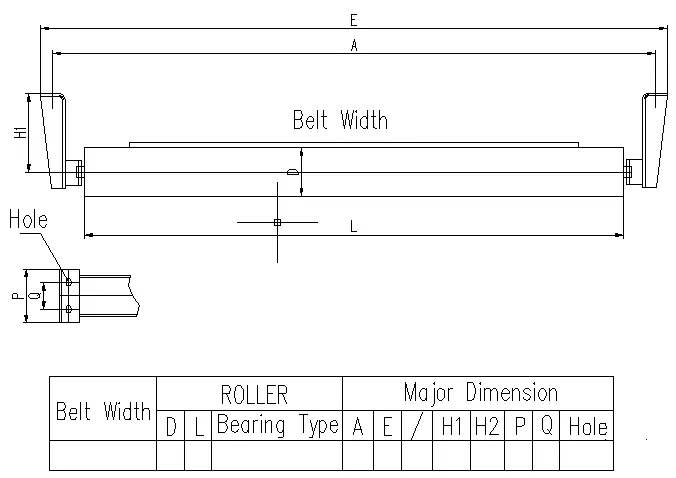

Belt conveyors are integral components of material handling systems across various industries, including mining, manufacturing, and logistics. One of the critical elements in the design and efficiency of belt conveyors is the idler. The idler, which supports the belt, plays a crucial role in ensuring that the conveyor system operates effectively and efficiently. In this article, we will explore the key aspects of belt conveyor idler design, including types, materials, load capacities, and maintenance considerations.

Types of Idlers

Belt conveyor idlers can be classified into several categories based on their design and application. The main types include

1. Carrying Idlers These idlers support the weight of the conveyed materials. Carrying idlers can further be categorized into troughing idlers, flat idlers, and transition idlers. Troughing idlers are the most common, with a curved design that allows for better containment of bulk materials.

2. Return Idlers Positioned on the return side of the conveyor, return idlers support the empty belt as it returns to the loading point. They help maintain proper belt tension and alignment.

3. Impact Idlers These are specially designed to absorb the shock of heavy bulk materials falling onto the conveyor. Impact idlers typically feature a robust construction to withstand significant forces.

4. Training Idlers These idlers are used to control the alignment of the conveyor belt. They help prevent belt mistracking and ensure that the belt runs straight along the conveyor path.

Materials and Construction

The materials used in idler construction significantly impact their performance, durability, and maintenance needs. Common materials include

- Steel Often used for heavy-duty application idlers due to its strength and ability to withstand harsh environments. Steel idlers are typically coated with anti-corrosive materials to extend their lifespan.

- Plastic Lightweight and resistant to moisture, plastic idlers are suitable for environments where corrosion is a concern. However, they may not be ideal for extremely heavy loads.

belt conveyor idler design

- Rubber Used primarily for impact idlers, rubber provides excellent shock absorption and can reduce belt wear.

The design of the idler also includes considerations for the size and weight. Idlers must be optimized for the specific loads they will carry, taking into account factors such as belt width, material type, and operating conditions.

Load Capacity and Performance

One of the critical parameters in idler design is the load capacity. This is defined by the amount of weight that an idler can support without deforming or failing. Engineers calculate load capacities by considering factors such as belt tension, angle of repose of the bulk material, and environmental conditions (like temperature and humidity).

Performance metrics, including frictional resistance and belt sag, are also considered during the design phase. A well-designed idler will minimize frictional losses, enhance material flow, and reduce wear on both the idler itself and the conveyor belt.

Maintenance Considerations

Regular maintenance of idlers is crucial to ensuring the longevity and efficiency of the entire conveyor system. Common maintenance practices include

- Inspection Periodic inspections can identify potential issues before they lead to failures. Key areas to inspect include roller rotation, alignment, and wear on the bearings.

- Lubrication Adequate lubrication of the bearings reduces friction and wear, extending the life of the idlers.

- Replacement Identifying when an idler has reached the end of its operational life is crucial. Signs of excessive wear or damage should prompt immediate replacement to prevent disruptions in the conveyor system.

Conclusion

In summary, the design of belt conveyor idlers is a multi-faceted process that plays a critical role in the overall performance and reliability of conveyor systems. Through careful consideration of types, materials, load capacities, and maintenance practices, engineers can create idler systems that support efficient material handling operations. By investing in quality idler design and maintenance, companies can reduce downtime, enhance productivity, and ultimately achieve more reliable supply chain operations. As technology advances, continued innovation in idler design will further improve the efficiency of belt conveyors across various industries.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025