Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu belt conveyor drum pulley manufacturers

The Importance of Belt Conveyor Drum Pulley Manufacturers

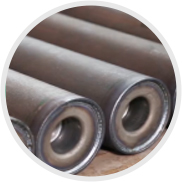

Belt conveyor systems are an indispensable part of various industries, offering an efficient means of transporting materials. At the heart of these systems is the drum pulley, which plays a crucial role in the functioning and efficiency of the conveyor. Thus, selecting reliable belt conveyor drum pulley manufacturers is vital for ensuring optimal performance in material handling applications.

Understanding the Function of Drum Pulleys

Drum pulleys are cylindrical components that serve multiple purposes in a belt conveyor system. Primarily, they are used to drive the conveyor belt, providing the necessary friction to pull the belt and transport materials along its length. These pulleys can be found in two configurations drive pulleys, which are located at the head of the conveyor and provide the drive force, and tail pulleys, located at the end of the conveyor and serving to support the belt's return path.

In addition to driving the belt, drum pulleys also assist in tensioning the belt, ensuring that it remains snugly fitted on the conveyor structure, thereby preventing slippage. Furthermore, they are intricately designed to withstand the wear and tear associated with heavy loads and rough operating conditions. This necessitates that drum pulleys are robustly constructed from high-quality materials to ensure longevity and reliability, which is why the choice of manufacturer is so crucial.

What to Look for in Belt Conveyor Drum Pulley Manufacturers

When searching for reputable belt conveyor drum pulley manufacturers, several factors should be considered

1. Quality of Materials The material from which the drum pulleys are made is critical in determining their durability. Manufacturers should use robust materials, often steel or resistant polymers, to ensure the pulleys can withstand mechanical stress and environmental conditions.

2. Manufacturing Standards Look for manufacturers that adhere to international quality standards, such as ISO certifications. This not only ensures the consistency and reliability of the products but also reflects the manufacturer’s commitment to quality and safety.

3. Customization Options Different applications may require specific dimensions and designs for drum pulleys. A good manufacturer should offer customization options to cater to unique requirements, including specialized coatings or surfaces that enhance durability.

belt conveyor drum pulley manufacturers

4. Technical Expertise Choose manufacturers with a track record of technical expertise in the industry. Their knowledge can be invaluable for providing insights into the best product choices for particular applications.

5. Customer Service and Support Reliable manufacturers will offer excellent customer service, providing support during the selection process, as well as after-sales support. This can include installation guidance, troubleshooting, and maintenance advice.

6. Reputation and Reviews Research potential manufacturers through customer reviews and testimonials. A solid reputation within the industry often correlates with product quality and customer satisfaction.

The Impact of Local Manufacturing

Opting for local belt conveyor drum pulley manufacturers can present several advantages. Local companies often provide quicker delivery times, reducing downtime for operations. Additionally, local manufacturers may have a better understanding of regional needs and challenges, ensuring that their products are tailored accordingly. Supporting local businesses also contributes to the economy and encourages future innovation within the industry.

The Future of Drum Pulley Manufacturing

As industries continue to evolve, advancements in technology will significantly impact the capabilities of belt conveyor drum pulley manufacturers. The integration of automation, IoT, and advanced materials science is set to revolutionize how drum pulleys are designed and produced. This will likely lead to even more efficient, durable, and intelligent pulley systems that enhance operations across a multitude of sectors.

Conclusion

Choosing the right belt conveyor drum pulley manufacturer is critical to the efficiency and reliability of any conveyor system. By considering factors such as material quality, manufacturing standards, customization options, and the manufacturer's reputation, businesses can make informed decisions that enhance their operations. The importance of partnering with dependable manufacturers cannot be overstated, as they contribute significantly to the productivity and safety of industrial processes. As technology advances, staying updated on new developments will ensure that conveyor systems are equipped with the best drum pulleys available in the market, leading to greater efficiency and operational success.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025