Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Top Manufacturers of Belt Conveyor Drums and Pulleys for Optimal Performance

Belt Conveyor Drum Pulley Manufacturers A Comprehensive Overview

In the realm of material handling and industrial processes, belt conveyors play a pivotal role in the efficient transportation of goods. A key component of these systems is the drum pulley, essential for the functionality and longevity of conveyor belts. This article aims to delve into the significance of belt conveyor drum pulley manufacturers, the characteristics of their products, and the benefits they bring to various industries.

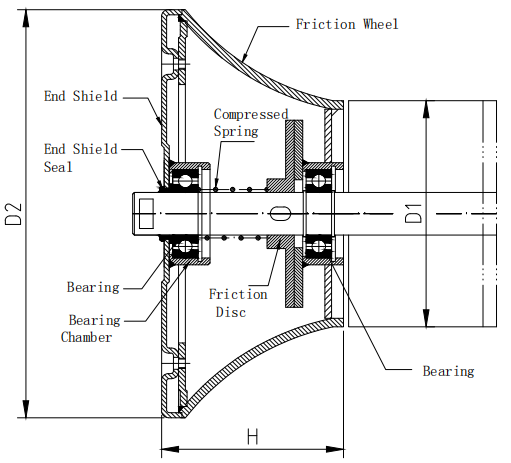

Understanding Drum Pulleys

Drum pulleys are cylindrical devices located at the ends of conveyor belts. Their primary function is to drive the belt and provide the necessary tension for optimal operation. The design and construction of drum pulleys can significantly impact the overall performance of the conveyor system. Drum pulleys come in various sizes and configurations, accommodating diverse applications ranging from light-duty to heavy-duty operations.

The Role of Manufacturers

Belt conveyor drum pulley manufacturers are specialized entities focused on designing, producing, and supplying these crucial components. Their expertise lies in understanding the unique requirements of different industries, including mining, agriculture, manufacturing, and logistics. These manufacturers employ advanced engineering techniques and high-quality materials to create durable and reliable drum pulleys that withstand the rigors of continuous operation.

Key Characteristics of High-Quality Drum Pulleys

1. Material Selection Quality drum pulleys are crafted from robust materials such as steel or aluminum, ensuring they can endure the weight and stress of the conveyor system. Galvanization or coating may also be applied to prevent corrosion and enhance longevity.

2. Precision Engineering The manufacturing process involves precise engineering to ensure that the drum pulleys are perfectly balanced. This is crucial to prevent vibrations that could lead to premature wear and tear of not only the pulley itself but the entire conveyor system.

3. Customization Options Since different industries have varying specifications, reputable manufacturers often provide customization options for their drum pulleys. This can include modifications in size, shape, and additional features to suit specific operational needs.

belt conveyor drum pulley manufacturers

4. Easy Maintenance Drum pulleys designed for ease of maintenance can significantly reduce downtime. Features such as removable covers or built-in inspection ports allow for quick checks and adjustments, ensuring the conveyor system runs smoothly.

5. Safety Features Reliable manufacturers prioritize safety, integrating features that protect both the equipment and personnel. This might include guards to prevent accidental contact or designs that minimize pinch points.

Benefits of Collaborating with Drum Pulley Manufacturers

1. Increased Efficiency By sourcing quality drum pulleys, businesses can enhance the efficiency of their conveyor systems. Well-manufactured pulleys operate more smoothly, reducing energy consumption and operational costs.

2. Durability and Reliability High-quality drum pulleys are an investment in the future; they offer increased durability, reducing the frequency of replacements and repairs, which can disrupt business operations.

3. Expert Consultation Manufacturers often provide consultancy services to help businesses select the best drum pulley for their specific needs. Their insights can lead to better performance and efficiency of conveyor systems.

4. Supply Chain Solutions Established manufacturers may offer comprehensive supply chain solutions, ensuring timely delivery of components, which is crucial for maintaining operational continuity.

Conclusion

Belt conveyor drum pulley manufacturers are essential partners in various industries reliant on material handling systems. Their capability to produce high-quality, customized drum pulleys ensures that conveyor systems operate efficiently and reliably. By investing in drum pulleys from reputable manufacturers, companies can enhance their operational performance, reduce downtime, and ensure a safe working environment. Whether in mining, manufacturing, or logistics, the role of drum pulleys cannot be understated, making the choice of manufacturer a critical decision for any business looking to optimize its conveyor systems.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025