Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 31, 2025 01:58

Back to list

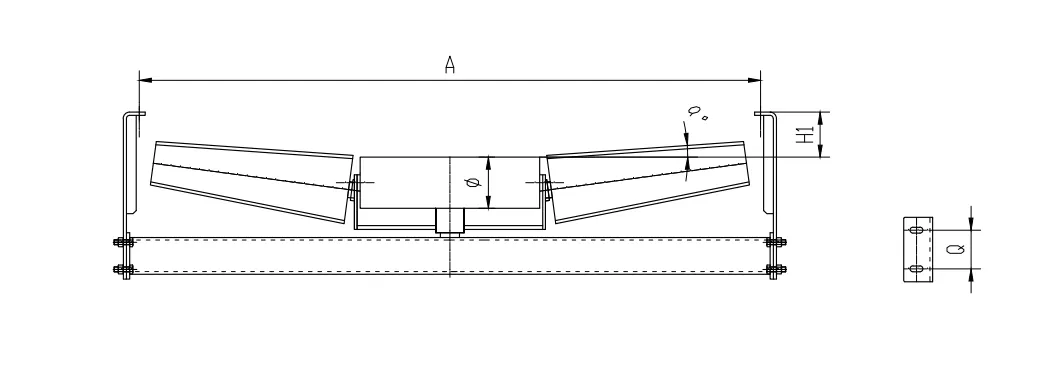

belt conveyor cleaner

Belt conveyor cleaners are integral components in material handling industries, playing a crucial role in optimizing operational efficiency and ensuring the longevity of the conveyor systems. These devices, tasked with removing residual material from the conveyor belt surface, are essential in maintaining cleanliness and preventing potential hazards that could lead to costly downtimes.

Reliable sources and case studies provide an added layer of trustworthiness to conveyor belt cleaner products. Testimonials from established companies that have realized tangible benefits from implementing these cleaners attest to their effectiveness and reliability. Data-driven results showcasing reduced downtime, enhanced productivity, and lowered operational costs serve as powerful endorsements for potential users considering these systems. Moreover, trust in these products is also built through transparency in the manufacturing process, including details about material sourcing, manufacturing techniques, and quality control procedures. Companies that openly share this information often enjoy higher levels of consumer confidence, as transparency demonstrates their commitment to quality and customer satisfaction. In conclusion, belt conveyor cleaners are pivotal in ensuring efficient, safe, and economical operations across various industries. With the right blend of expertise and technology, these devices provide significant value by preserving the integrity of conveyor belts and reducing operational hiccups. As industries continue to demand improved productivity and cost-effectiveness, the role of belt conveyor cleaners remains indispensable, underscored by their proven track record of enhancing operational efficiency and sustainability.

Reliable sources and case studies provide an added layer of trustworthiness to conveyor belt cleaner products. Testimonials from established companies that have realized tangible benefits from implementing these cleaners attest to their effectiveness and reliability. Data-driven results showcasing reduced downtime, enhanced productivity, and lowered operational costs serve as powerful endorsements for potential users considering these systems. Moreover, trust in these products is also built through transparency in the manufacturing process, including details about material sourcing, manufacturing techniques, and quality control procedures. Companies that openly share this information often enjoy higher levels of consumer confidence, as transparency demonstrates their commitment to quality and customer satisfaction. In conclusion, belt conveyor cleaners are pivotal in ensuring efficient, safe, and economical operations across various industries. With the right blend of expertise and technology, these devices provide significant value by preserving the integrity of conveyor belts and reducing operational hiccups. As industries continue to demand improved productivity and cost-effectiveness, the role of belt conveyor cleaners remains indispensable, underscored by their proven track record of enhancing operational efficiency and sustainability.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS