Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu belt conveyor accessories

Understanding Belt Conveyor Accessories Their Importance and Applications

Belt conveyors are an essential component in various industries, serving as a proficient medium for transporting materials. However, to maximize efficiency and ensure the longevity of these systems, it is crucial to understand the various accessories that support their operation. These accessories not only enhance the functionality of the conveyor system but also ensure safe and effective transport of materials.

Types of Belt Conveyor Accessories

1. Conveyor Belts The primary component of any belt conveyor system, conveyor belts come in various materials such as rubber, plastic, and metal, each suited for different applications. The choice of belt material affects the conveyor's performance, durability, and maintenance requirements.

2. Pulleys Pulleys are critical in facilitating the movement of the belt. They drive the conveyor and can be classified into various types, including drive pulleys, return pulleys, and tail pulleys. Drive pulleys are connected to the motor and provide the necessary drive force for the belt, while return pulleys guide the belt back to the loading point.

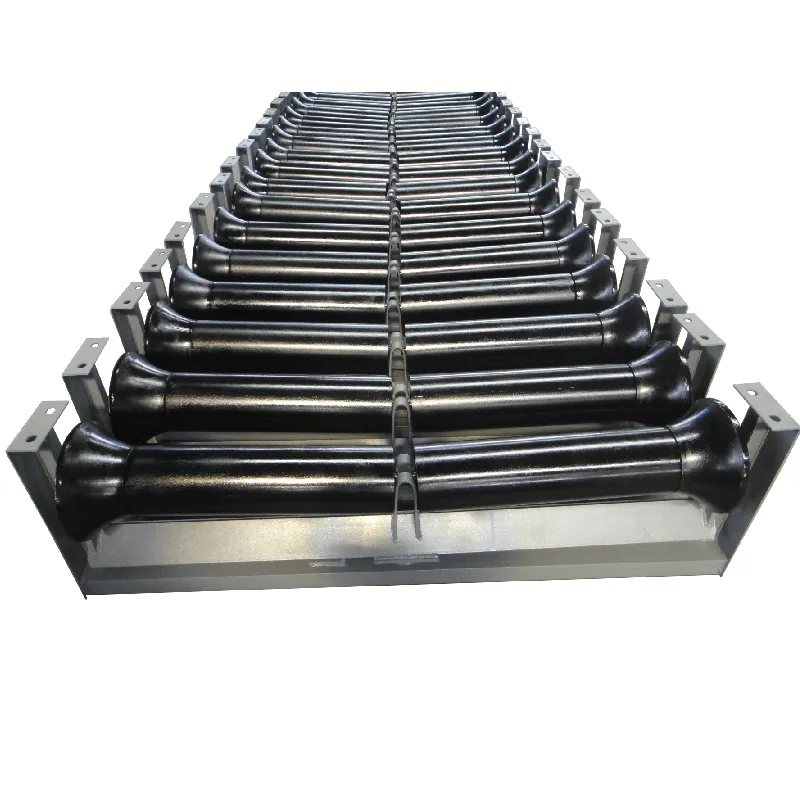

3. Idlers Idlers are support rollers that maintain the belt's alignment and reduce friction during operation. They are strategically placed along the conveyor path. Proper idler selection is vital for preventing belt sagging and ensuring a consistent load distribution.

4. Belt Cleaners These accessories are essential for maintaining a clean conveyor system. Belt cleaners are designed to remove materials that adhere to the belt’s surface, preventing carryback and improving operational efficiency. They significantly reduce maintenance downtime and enhance safety by minimizing slip and fall hazards.

5. Safety Devices Safety is paramount in conveyor systems, and several accessories are designed to enhance safety features. Emergency stop switches, belt misalignment detectors, and guardrails protect operators and the machinery. Implementing these safety measures helps prevent accidents and supports compliance with regulatory standards.

6. Skeletals and Frame Structures The skeletal structure of the conveyor system provides the necessary support and integrity of the entire assembly. Made from steel or other robust materials, these frame structures ensure that the conveyor can handle heavy loads without compromising stability.

belt conveyor accessories

Importance of Belt Conveyor Accessories

The right accessories can considerably enhance the efficiency, safety, and longevity of conveyor systems. Here are some key reasons why these accessories are vital

- Efficiency and Productivity Accessories like belt cleaners and idlers significantly improve the efficiency of the conveyor system. By reducing material buildup and ensuring smooth belt travel, these accessories allow for uninterrupted operations, leading to increased productivity.

- Cost-Effectiveness Investing in quality accessories can reduce long-term operational costs. For example, effective belt cleaners can minimize belt wear and tear, thereby extending its lifespan and reducing replacement costs. Similarly, well-maintained pulleys and idlers lower energy consumption by optimizing belt movement.

- Safety Safety devices are critical in any industrial environment. Accessories that promote safety not only protect the workforce but also safeguard the material being transported. By preventing accidents, companies can avoid legal issues and costly downtime.

- Customization The wide range of available accessories allows for customization of the conveyor systems to meet specific operational needs. Whether it is transporting delicate products or handling heavy materials, choosing the right accessories ensures the conveyor system can perform optimally under varying conditions.

Conclusion

Belt conveyor accessories play a pivotal role in enhancing the performance of conveyor systems across diverse industries. Understanding their types and functions helps in making informed choices for maintaining and upgrading conveyor systems. Investing in quality accessories not only improves efficiency and productivity but also contributes to a safer working environment. As industries continue to evolve, the demand for advanced conveyor solutions will grow, emphasizing the need for reliable accessories in achieving operational excellence. In this dynamic landscape, ensuring that belt conveyor accessories are regularly inspected, maintained, and upgraded will ultimately determine the success of material handling operations.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025