Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu belt and pulley drive

Understanding Belt and Pulley Drives Mechanisms and Applications

Belt and pulley drives are fundamental components in mechanical engineering, widely utilized in various machines and systems to transfer power and motion. This system consists of a belt, typically made from flexible materials like rubber or fabric, that runs over pulleys, which are circular wheels that rotate to create motion. The simplicity, efficiency, and versatility of belt and pulley drives have made them integral to many applications, from manufacturing to household appliances.

Basic Components of Belt and Pulley Drives

The core components of a belt and pulley system include the belt and the pulleys. The belt connects two or more pulleys, translating rotational motion and power from one pulley to another. Pulleys can vary in size, with larger pulleys rotating more slowly and smaller ones rotating faster. This size difference allows for a mechanical advantage, where the output speed and torque can be manipulated according to the specific needs of the application.

Pulleys are classified into different types, primarily fixed, movable, and compound pulleys. Fixed pulleys simply change the direction of the force applied, whereas movable pulleys provide a mechanical advantage by effectively reducing the amount of force needed to lift an object. Compound pulleys combine both fixed and movable pulleys, optimizing efficiency and effectiveness in lifting.

Types of Belts

Belt materials can significantly affect the performance of the drive system. Common belt types include flat belts, V-belts, and synchronous belts. Flat belts are primarily used in low-speed applications where mechanical wear is not an issue. V-belts, with their wedge-shaped cross-section, provide a better grip and are suitable for higher torque applications, as they can transmit power efficiently without slipping. Synchronous belts have teeth on their inner surface, allowing for precise movement and timing, making them ideal for applications where synchronization is critical, such as in robotics and automotive timing systems.

Advantages of Belt and Pulley Drives

belt and pulley drive

Belt and pulley drives offer several advantages over other power transmission methods. Firstly, they are relatively inexpensive to produce and maintain, making them an attractive choice for both industrial and domestic applications. Moreover, their ability to transmit high torque with minimal wear and noise makes them desirable in environments where efficiency and noise reduction are critical.

These systems also allow for flexibility in design. The distance between pulleys can be adjusted, and various pulley sizes can be selected to achieve desired speed ratios. This adaptability enhances the functionality of machinery, allowing for customization to meet specific operational requirements.

Applications

Belt and pulley drives are ubiquitous in various industries and applications. They are commonly found in conveyor systems, where belts transport goods efficiently over short or long distances. In automobiles, they are used in the timing belt system and to drive accessories like the alternator and water pump. Industrial machinery often utilizes belt drives to connect motors to various components, ensuring smooth and effective operation.

In household applications, examples can be found in washing machines, where pulley systems allow for the control of drum speeds, enhancing the efficacy of washing cycles. Even in fitness equipment, such as treadmills and stationary bikes, belt drives play a key role in providing a smooth user experience.

Conclusion

In conclusion, belt and pulley drives are essential mechanisms that play a critical role in the functionality of numerous machines across various industries. Their effective power transmission, adaptability, and cost-efficiency make them a preferred choice for engineers and manufacturers alike. As technology advances, the design and materials used in belt and pulley systems are also evolving, promising further improvements in efficiency and application. Whether in an industrial setting or everyday consumer products, understanding the principles and applications of belt and pulley drives is vital for appreciating their significance in our engineered world.

-

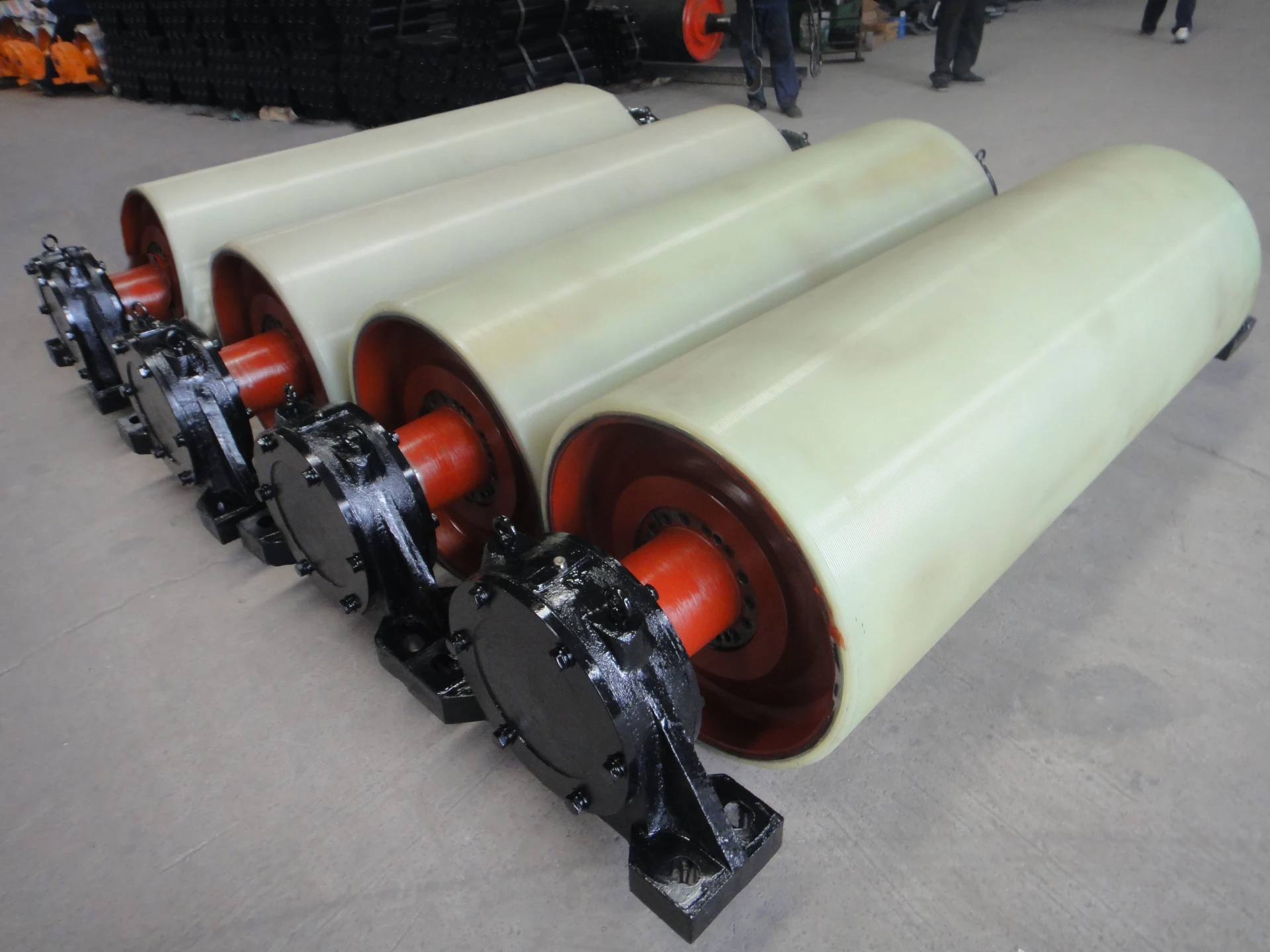

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025