Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Belt Wiper - Efficient Conveyor Cleaning Solutions

The Importance of Belt Wipers in Modern Manufacturing

In the contemporary landscape of manufacturing and production, the efficiency and functionality of machinery play a crucial role in the overall productivity of a company. One often overlooked yet vital component in many industrial applications is the belt wiper. These devices serve essential functions that contribute not only to the maintenance of equipment but also to the quality of the end products.

A belt wiper is specifically designed to clean conveyor belts and related machinery components during operation. The primary purpose of these wipers is to remove debris, dust, and other contaminants that can accumulate on belts as they transport materials. This cleaning process is vital because any buildup can lead to a range of issues, including decreased efficiency, increased wear and tear on machinery, and potential contamination of products.

One of the significant advantages of implementing belt wipers is the prevention of product contamination. In industries such as food processing, pharmaceuticals, and electronics, maintaining cleanliness and adhering to strict hygiene standards is paramount. A contaminated belt can lead to defective products, recalls, and damage to a company’s reputation. Belt wipers help mitigate these risks by ensuring that the belts are kept clean, thereby contributing to higher quality standards.

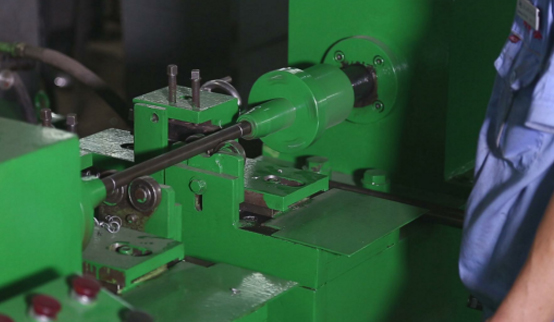

belt wiper

Another critical aspect of belt wipers is their role in equipment longevity. Machinery that operates constantly with dirty belts can suffer from increased friction, heat, and wear. This can lead to more frequent breakdowns and repairs, resulting in unexpected downtime and increased operational costs. By maintaining clean belts, manufacturers can significantly extend the lifespan of their equipment, reducing maintenance costs and enhancing productivity.

Moreover, the installation of belt wipers can lead to improved operational efficiency. With cleaner belts, there is less likelihood of products slipping or becoming stuck, which can disrupt production lines. This smooth operation ensures a steady flow of materials and minimizes the chances of bottlenecks, allowing for quicker turnaround times and better resource management.

In addition to their practical benefits, belt wipers also contribute to the safety of the workplace. A clean environment reduces the risk of accidents caused by slipping or tripping over debris. Ensuring that machinery runs smoothly and is well-maintained also means fewer hazards associated with malfunctioning equipment, creating a safer workplace for employees.

In conclusion, belt wipers are an essential component of modern manufacturing processes. Their ability to maintain cleanliness, enhance equipment longevity, improve operational efficiency, and contribute to workplace safety highlights their significance. Companies that invest in high-quality belt wipers can reap the rewards of increased productivity, reduced costs, and higher standards of quality assurance. As industries continue to evolve and demand greater efficiency, the role of belt wipers in maintaining optimal performance will undoubtedly remain crucial.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025