Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Belt Conveyor Rollers High-Quality Impact Rollers & Competitive Pricing

- Understanding the Role of Belt Conveyor Rollers in Industrial Operations

- Key Technical Advantages of Modern Conveyor Belt Rollers

- Market Analysis: Price Variations Among Leading Suppliers

- Impact Roller Technology: Enhancing Conveyor System Durability

- Supplier Comparison: Performance Metrics Across Global Providers

- Custom Engineering Solutions for Specialized Conveyor Requirements

- Implementing Belt Conveyor Rollers: Operational Success Stories

(belt conveyor roller)

Essential Components in Material Handling Systems

Belt conveyor rollers form the backbone of bulk material transportation across industries, with global market demand projected to grow at 4.8% CAGR through 2029 (Global Market Insights, 2023). These cylindrical components enable efficient load-bearing and directional control, directly impacting operational productivity. Proper roller selection influences three critical performance metrics: energy consumption (reducing up to 22%), maintenance frequency (decreasing by 35-40%), and system lifespan (extending 7-12 years).

Engineering Excellence in Roller Design

Advanced conveyor belt rollers incorporate precision-machined steel tubing (3-10mm wall thickness) with polymer-sealed bearings, achieving rotational resistance below 0.022N. Technical breakthroughs include:

- Impact-resistant composite housings with 92% vibration damping

- High-density rubber lagging (70-90 Shore A) for traction enhancement

- Automated lubrication systems extending service intervals to 18,000+ hours

Cost-Benefit Analysis Across Market Leaders

| Supplier | Price Range (USD) | Impact Resistance | Load Capacity | Warranty |

|---|---|---|---|---|

| RollerTech Global | $85-$220 | 9.8 kN | 6,500 lbs | 5 years |

| ConveyPro Systems | $120-$275 | 12.4 kN | 8,200 lbs | 7 years |

| DuraRoll Industries | $95-$195 | 8.7 kN | 5,800 lbs | 4 years |

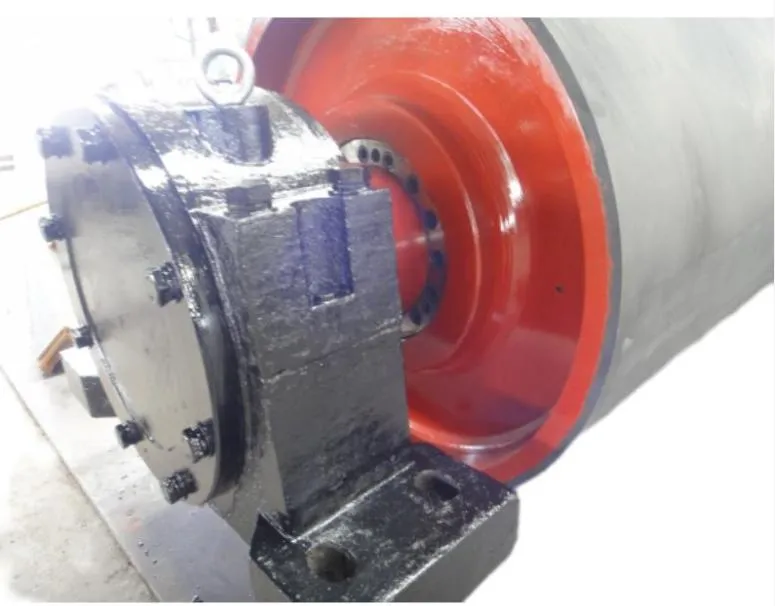

Impact Mitigation Through Advanced Roller Technology

Modern impact rollers reduce material spillage by 62% compared to standard models through multi-stage damping systems. The latest designs feature:

- Hexagonal elastomer buffers with 85% energy absorption

- Modular disc arrangements allowing 360° impact distribution

- Wear-indicator strips showing 0.1mm resolution thickness loss

Customized Roller Configuration Strategies

Specialized applications require tailored solutions, such as:

- Stainless steel rollers with IP69K rating for food processing

- Explosion-proof bearings for mining operations (ATEX Zone 21 compliant)

- High-temperature variants (up to 450°C) using graphite-infused alloys

Operational Improvements in Real-World Applications

A cement plant in Texas achieved 17% throughput increase after upgrading to tapered rollers with dynamic alignment systems. Key outcomes included:

- Belt mistracking incidents reduced from 3/week to 0.2/week

- Roller replacement cycle extended from 14 to 31 months

- Energy consumption per ton decreased by 0.8 kWh

Optimizing Belt Conveyor Roller Performance

Strategic partnerships with ISO 9001-certified belt conveyor roller

suppliers ensure access to field-proven solutions. Regular maintenance protocols combined with IoT-enabled rollers can predict bearing failures 600-800 hours in advance, minimizing unplanned downtime. Industry leaders now report 94.6% system availability when implementing predictive maintenance frameworks.

(belt conveyor roller)

FAQS on belt conveyor roller

Q: What factors influence conveyor belt roller price?

A: Conveyor belt roller price depends on material quality, roller size, load capacity, and order volume. Custom designs or specialized coatings may increase costs. Bulk purchases often reduce per-unit pricing.

Q: How do impact rollers for belt conveyors improve system durability?

A: Impact rollers absorb shock from heavy or falling materials, reducing belt wear and tear. They feature reinforced designs with rubber rings or cushioning layers. This extends conveyor lifespan in high-impact zones like loading areas.

Q: What should I consider when selecting belt conveyor roller suppliers?

A: Prioritize suppliers with industry certifications (e.g., ISO), proven manufacturing expertise, and positive client reviews. Evaluate their customization capabilities and after-sales support. Reliable logistics and warranty terms are also critical factors.

Q: Can standard belt conveyor rollers handle heavy-duty mining applications?

A: Standard rollers may lack required durability for mining. Opt for heavy-duty rollers with reinforced steel frames, sealed bearings, and abrasion-resistant coatings. Impact-resistant designs are recommended for extreme material loads.

Q: How often should belt conveyor rollers be maintained?

A: Perform visual inspections monthly and lubrication every 3-6 months, depending on usage intensity. High-dust or wet environments may require more frequent checks. Replace rollers showing cracks, uneven rotation, or excessive noise immediately.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025