Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 25, 2025 21:26

Back to list

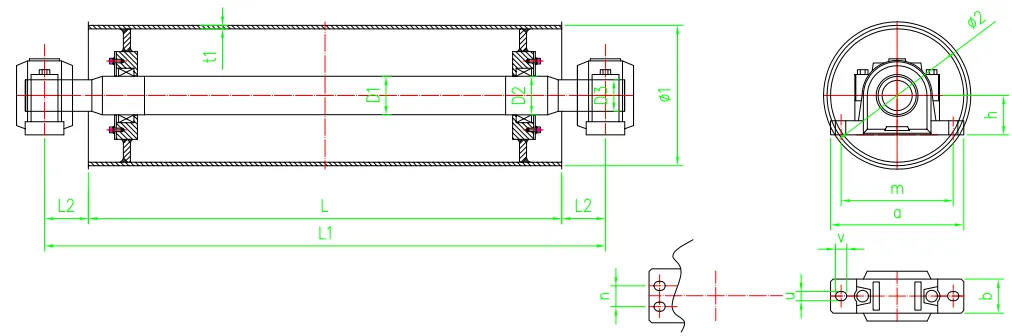

bearing housing types

Bearing housing is integral to the functionality and longevity of numerous mechanical systems, with its primary role being to support bearings effectively within various applications. Understanding the different types of bearing housings is essential for professionals seeking to optimize machinery performance, reduce downtime, and extend operational life. The following exploration presents a comprehensive guide to the most prevalent bearing housing types, infused with expert insights and practical experiences.

Another sophisticated housing type is the cartridge housing, recognized for its compact and protective design. Cartridge housings are prevalent in marine applications due to their robust sealed enclosures that defend against contamination and water ingress. Experience in the field shows that cartridge housings not only safeguard the bearings but also extend service intervals, bolstering system steadiness in harsh environments. Bearing ready-to-mount units represent a modern evolution of housing efficiency, incorporating housing units with pre-assembled mechanical components. This integration allows rapid installation and minimal technical skill requirements. Ideal for industries facing skilled labor shortages, these units decrease installation errors and promote immediate operational readiness. There are also custom housings crafted for specific applications where standard solutions are inadequate. These tailor-made solutions leverage advanced materials and design principles to meet niche requirements. Real-world application highlights the efficacy of these solutions in aerospace and cutting-edge automotive sectors where precision engineering is paramount. For organizational leaders and maintenance professionals invested in prolonging equipment lifespan and enhancing operational efficiency, understanding these bearing housing types is crucial. Leveraging the right housing design for the specific application can translate to significant cost savings, improved machine performance, and enhanced reliability. In sum, bearing housings are more than mere support structures; they are critical components in the optimization of mechanical systems. Professionals armed with a deep understanding of bearing housing types can drive innovation and operational excellence by matching the right housing type to the right application. This knowledge, steeped in experience and expertise, empowers industry professionals to make informed decisions, establish authoritative practices, and build trust within their respective fields.

Another sophisticated housing type is the cartridge housing, recognized for its compact and protective design. Cartridge housings are prevalent in marine applications due to their robust sealed enclosures that defend against contamination and water ingress. Experience in the field shows that cartridge housings not only safeguard the bearings but also extend service intervals, bolstering system steadiness in harsh environments. Bearing ready-to-mount units represent a modern evolution of housing efficiency, incorporating housing units with pre-assembled mechanical components. This integration allows rapid installation and minimal technical skill requirements. Ideal for industries facing skilled labor shortages, these units decrease installation errors and promote immediate operational readiness. There are also custom housings crafted for specific applications where standard solutions are inadequate. These tailor-made solutions leverage advanced materials and design principles to meet niche requirements. Real-world application highlights the efficacy of these solutions in aerospace and cutting-edge automotive sectors where precision engineering is paramount. For organizational leaders and maintenance professionals invested in prolonging equipment lifespan and enhancing operational efficiency, understanding these bearing housing types is crucial. Leveraging the right housing design for the specific application can translate to significant cost savings, improved machine performance, and enhanced reliability. In sum, bearing housings are more than mere support structures; they are critical components in the optimization of mechanical systems. Professionals armed with a deep understanding of bearing housing types can drive innovation and operational excellence by matching the right housing type to the right application. This knowledge, steeped in experience and expertise, empowers industry professionals to make informed decisions, establish authoritative practices, and build trust within their respective fields.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS