Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Types of Bearing Housings and Their Applications in Mechanical Systems

Understanding Bearing Housing Types An Essential Guide

Bearing housings play a crucial role in various industrial applications. They provide support and protection for bearings, ensuring smooth operation and longevity of machines. This article explores different types of bearing housings, their designs, and applications, helping you understand their importance in machinery.

What is a Bearing Housing?

A bearing housing, also known as a bearing pedestal or bearing box, is an assembly that encases a bearing. It is designed to support the bearing while keeping it in alignment during operation. The primary functions of bearing housings include reducing friction, managing heat, and protecting bearings from dust and other contaminants. They are often made from materials like cast iron, steel, or plastic, depending on the application and the environmental conditions they will face.

Types of Bearing Housings

Bearing housings can be classified into several types based on their design and application. Here are some of the most common types

1. Plummer Blocks (Pillow Blocks) Plummer blocks are one of the most widely used types of bearing housings. They provide ease of installation and maintenance and are commonly utilized in heavy machinery applications such as conveyor systems and pumps. Plummer blocks can accommodate various bearing types, including spherical roller bearings and tapered roller bearings. Their design allows for the adjustment of the bearing, which is essential for accommodating misalignment.

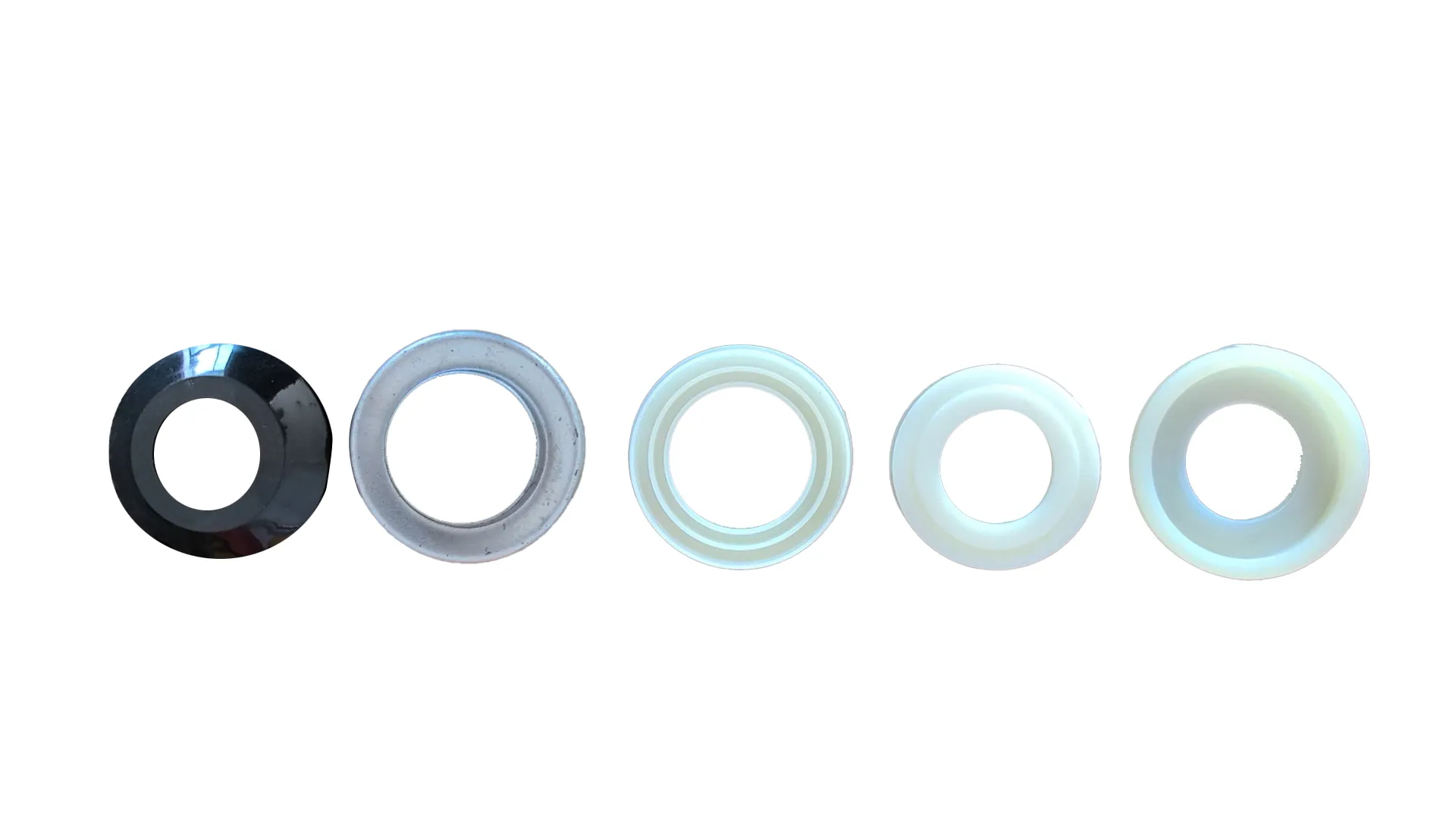

bearing housing types

2. Flange Mounted Bearing Housings Flange mounted bearing housings are designed to be attached to a surface or a frame using bolts. They excel in applications where vertical or horizontal space is limited. These housings are often used in electric motors, fans, and other machinery where alignment and stability are critical. The integrated flange allows for easy mounting and provides a secure and rigid connection.

3. Take-Up Housings Take-up housings are specifically designed to allow for adjustment in tension and alignment. These housings are crucial in systems where conveyor belts or chains are used, as they enable operators to easily tension the drive components. They offer versatility and ease of maintenance, making them essential for various material handling applications.

4. Adapter Housings Adapter housings are used for mounting spherical roller bearings onto a shaft. They allow for misalignment between the shaft and the housing, making them suitable for applications with higher shaft deflection. Adapter housings facilitate easy installation while ensuring that the bearing remains securely positioned.

5. Split Housings Split housings are designed to simplify maintenance and replacement of bearings. This design allows the housing to be split into two halves, enabling easy access to the bearing without needing to remove the entire assembly. Split housings are ideal for large machinery in industries such as mining and heavy manufacturing, where downtime is costly.

Conclusion

Understanding the various types of bearing housings is essential for selecting the right component for your machinery. Each type offers unique advantages, catering to specific application requirements and operational conditions. Choosing the appropriate bearing housing can enhance equipment efficiency, reduce maintenance efforts, and prolong the lifespan of the bearings themselves.

Whether you need a plummer block for a heavy conveyor system or a flange-mounted housing for a compact motor, recognizing the attributes of each type will lead to better performance and reliability in your industrial applications. As technology continues to evolve, manufacturers constantly innovate bearing housing designs, ensuring they meet the demands of modern machinery and industry standards. By staying informed about these developments, engineers and technicians can make more informed decisions and optimize machine performance.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025