Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 25, 2025 22:36

Back to list

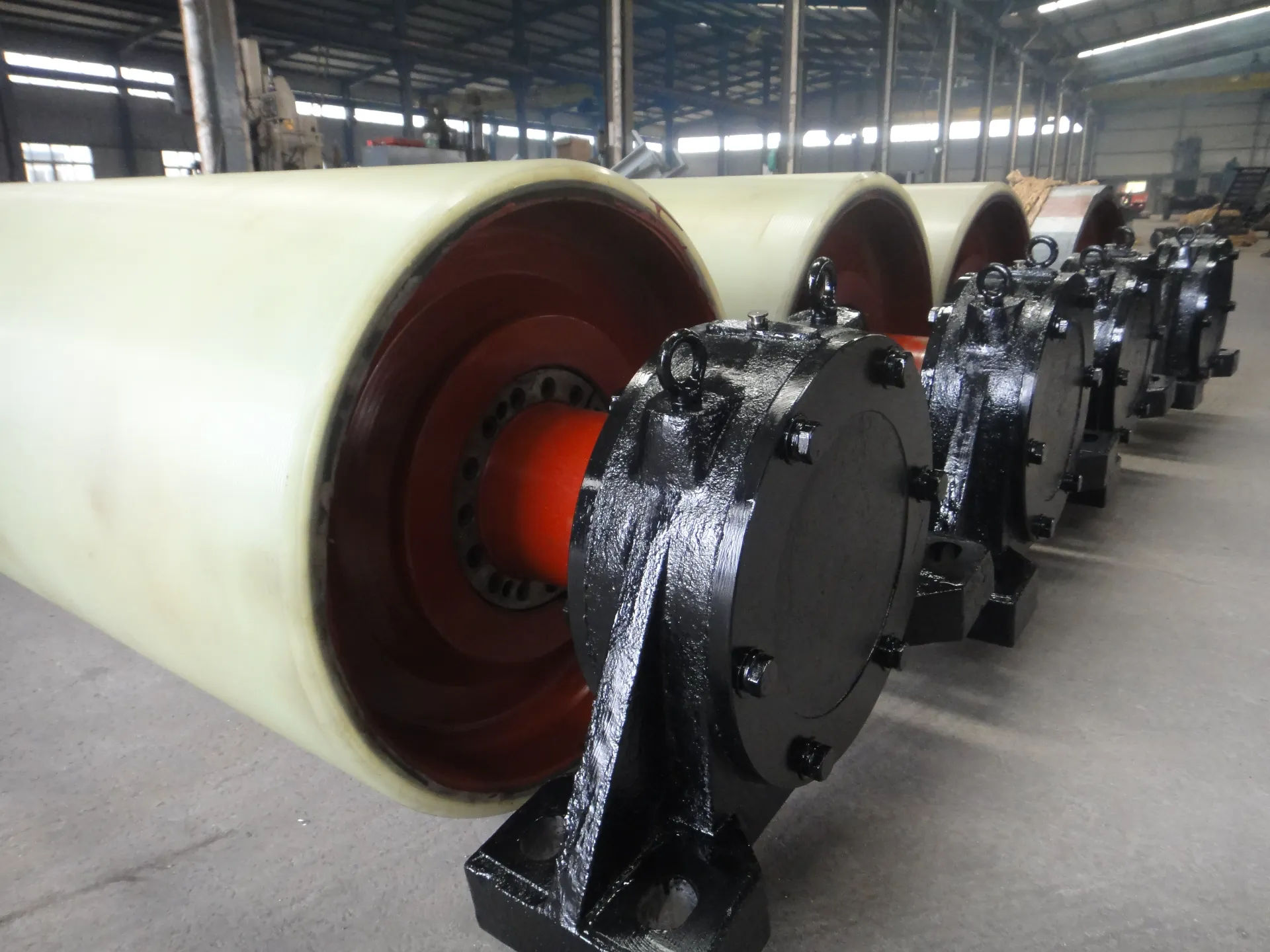

conveyor bearing housing

The bearing housing, an integral component in countless industrial applications, serves as the protective environment for bearings, ensuring their steady performance and enhanced longevity. In recent years, evaluating the price of bearing housings has become crucial for businesses aiming to maintain cost-effectiveness without compromising on quality. Understanding the factors influencing bearing housing prices empowers companies to make informed purchasing decisions, balancing budget constraints with performance requirements.

Volume purchase agreements and long-term partnerships with suppliers can significantly affect pricing structures. Businesses committing to bulk purchases or establishing enduring relationships with vendors can leverage discounts. Such arrangements foster mutual trust and can lead to beneficial auxiliary services such as on-site support or extended warranty periods without additional costs. Technological enhancements in bearing housings are progressively shaping price trends. The integration of IoT-enabled devices allows for smart housings capable of self-assessment, offering considerable operational efficiencies. While upfront costs are higher, the return on investment through minimized downtime and maintenance creates tangible long-term benefits. In evaluating such technologies, a comprehensive cost-benefit analysis tailored to specific operational contexts is crucial for optimal procurement strategies. Finally, sustainability considerations are emerging as key pricing determinants. With increasing regulatory and consumer pressure towards eco-friendliness, housings manufactured using sustainable practices or recyclable materials are in demand. Companies with environmental stewardship objectives may willingly accept higher costs for sustainably sourced housings, integrating them into their corporate social responsibility goals and market positioning strategies. In summary, understanding the multifaceted factors that contribute to the pricing of bearing housings is essential for businesses aiming to optimize both performance and expenditure. Material choice, manufacturing complexity, global supply dynamics, brand reputation, purchase volume, technological innovations, and sustainability all converge to influence price structures. An informed approach, balancing these variables against operational objectives and financial frameworks, will ensure that investments in bearing housings are strategically sound, fostering both immediate and long-term industrial success.

Volume purchase agreements and long-term partnerships with suppliers can significantly affect pricing structures. Businesses committing to bulk purchases or establishing enduring relationships with vendors can leverage discounts. Such arrangements foster mutual trust and can lead to beneficial auxiliary services such as on-site support or extended warranty periods without additional costs. Technological enhancements in bearing housings are progressively shaping price trends. The integration of IoT-enabled devices allows for smart housings capable of self-assessment, offering considerable operational efficiencies. While upfront costs are higher, the return on investment through minimized downtime and maintenance creates tangible long-term benefits. In evaluating such technologies, a comprehensive cost-benefit analysis tailored to specific operational contexts is crucial for optimal procurement strategies. Finally, sustainability considerations are emerging as key pricing determinants. With increasing regulatory and consumer pressure towards eco-friendliness, housings manufactured using sustainable practices or recyclable materials are in demand. Companies with environmental stewardship objectives may willingly accept higher costs for sustainably sourced housings, integrating them into their corporate social responsibility goals and market positioning strategies. In summary, understanding the multifaceted factors that contribute to the pricing of bearing housings is essential for businesses aiming to optimize both performance and expenditure. Material choice, manufacturing complexity, global supply dynamics, brand reputation, purchase volume, technological innovations, and sustainability all converge to influence price structures. An informed approach, balancing these variables against operational objectives and financial frameworks, will ensure that investments in bearing housings are strategically sound, fostering both immediate and long-term industrial success.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS