Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Analysis of Bearing Housing Pricing Trends and Market Influences

Understanding Bearing Housing Prices An Essential Guide

Bearing housings play a crucial role in various machinery and equipment, providing support and protection for bearings, which are vital components in reducing friction and wear. The price of bearing housings can fluctuate significantly based on several factors, and understanding these can help businesses make informed purchasing decisions.

Materials and Design

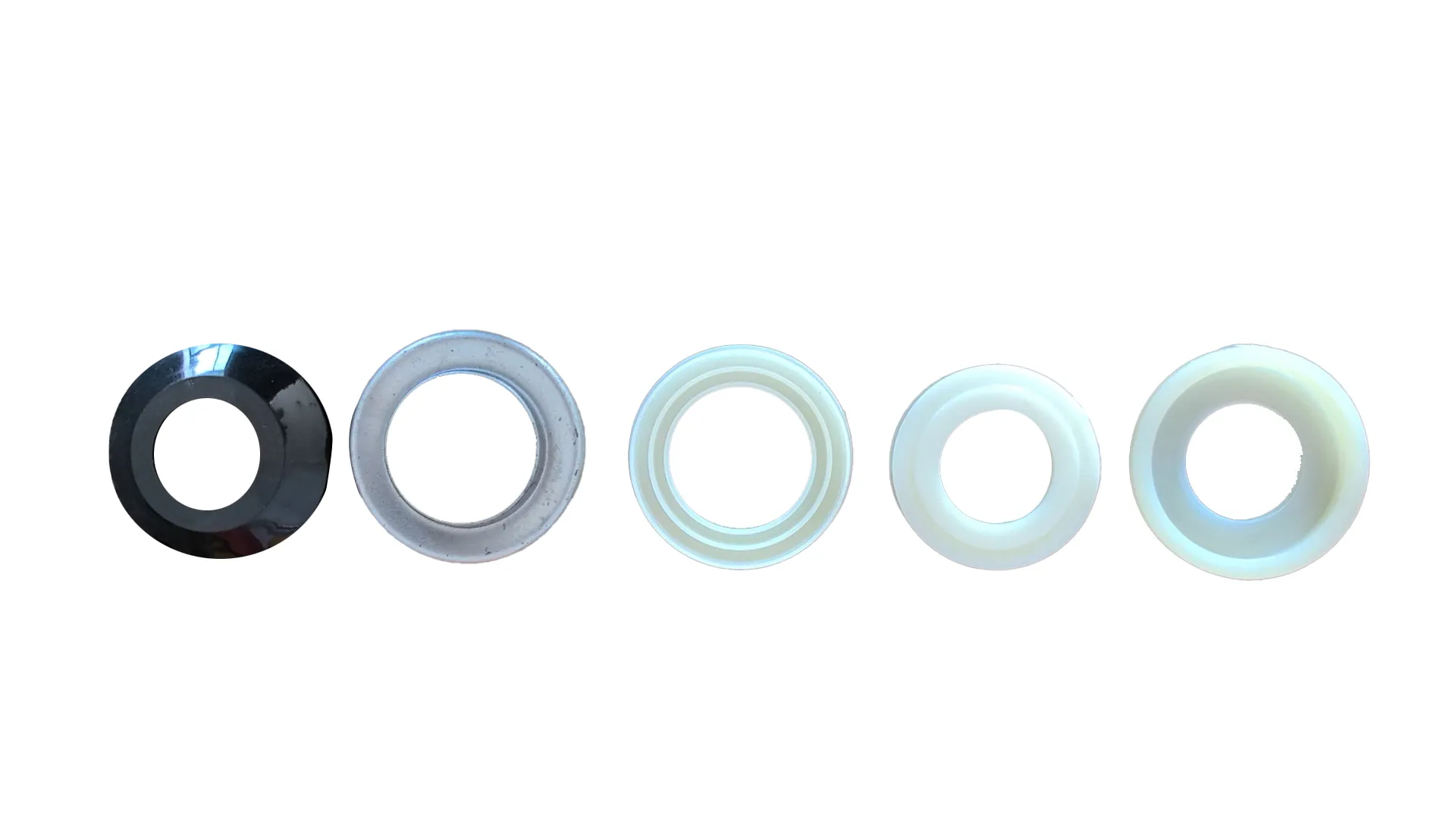

One of the primary determinants of bearing housing prices is the material used in their manufacturing. Common materials include cast iron, steel, and plastic, each with its own cost implications. For instance, cast iron is durable and corrosion-resistant but may be more expensive than basic plastics. Moreover, specialized designs, such as those incorporating features for enhanced lubrication or cooling, can also drive up costs. Tailored solutions, while ensuring longevity and productivity, can be a significant investment.

Manufacturing Processes

The way bearing housings are manufactured affects their final price. Precision machining, often required for high-performance applications, can lead to higher costs due to the intricate processes involved. Conversely, mass-produced units may offer lower prices. The trade-off between cost and quality is a key consideration for procurement decisions. Buyers must evaluate whether a lower initial price could lead to higher maintenance or replacement costs down the line.

bearing housing price

Market Demand and Trends

Supply and demand dynamics significantly influence bearing housing prices. In sectors experiencing rapid growth—like renewable energy or electric vehicles—the demand for specialized bearing housings can surge, leading to price increases. Conversely, economic downturns can lead to reduced demand and consequently lower prices. Staying informed about market trends is crucial for companies aiming to optimize their expenditures.

Brand and Supplier Reputation

The brand and reputation of suppliers also contribute to pricing. Established manufacturers with a history of producing high-quality products may command higher prices due to perceived reliability and performance. In contrast, lesser-known brands might offer more competitive pricing but could come with risks regarding quality and after-sales support. It is essential for buyers to conduct thorough research and weigh the benefits of buying from reputable sources against potential savings from lower-cost alternatives.

Conclusion

In conclusion, several factors influence bearing housing prices, including materials, manufacturing processes, market dynamics, and supplier reputation. By understanding these elements, businesses can make more strategic purchasing decisions, ensuring that they balance cost with quality and performance. As technology advances and industries evolve, staying informed about these factors will be essential for maintaining operational efficiency and competitiveness.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025