Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu bearing housing manufacturer

Understanding Bearing Housing Manufacturers The Cornerstone of Machinery Performance

In the realm of machinery and equipment design, bearing housings play a crucial role in ensuring smooth and efficient operations. These components house the bearings that support rotating shafts, and their design and production are fundamental to the overall performance of mechanical systems. Bearing housing manufacturers specialize in creating these essential components, and understanding their role can provide insights into machinery performance and longevity.

What is Bearing Housing?

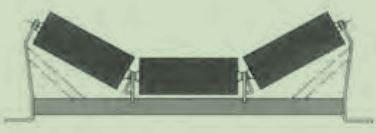

Bearing housings are sturdy enclosures that provide support and protection to bearings within machinery. They serve multiple purposes, including alignment, lubrication, and protection from environmental factors such as dust and moisture. The design of the housing must accommodate the specific type of bearing being used and the conditions under which it will operate. Manufacturers often offer a range of designs, including pillow blocks, flange mounts, and take-up units, each tailored to different applications.

The Role of Manufacturers

Bearing housing manufacturers are integral to the machinery supply chain. They not only produce standard products but also collaborate with engineers and designers to create customized solutions that meet specific project requirements. Their expertise in materials, design, and engineering practices ensures that the bearing housings can withstand various operating conditions, including extreme temperatures, pressure, and loads.

Quality is paramount in the manufacturing of bearing housings. Manufacturers must adhere to stringent industry standards to ensure durability and reliability. This involves sourcing high-quality raw materials, employing advanced manufacturing techniques, and implementing rigorous quality control processes. Many manufacturers also invest in research and development to innovate and improve their products continually.

bearing housing manufacturer

Material Selection

The choice of material for bearing housings is critical, as it directly affects the performance and lifespan of the component. Common materials include cast iron, aluminum, and various plastics. Cast iron is favored for its strength and durability, making it ideal for heavy-duty applications. On the other hand, aluminum offers advantages in weight savings and corrosion resistance, suitable for lighter applications or environments. Some manufacturers may also use composite materials to enhance performance in specific conditions.

Environmental Considerations

With the increasing focus on sustainability, bearing housing manufacturers are also integrating environmentally friendly practices into their operations. This includes using recyclable materials and minimizing waste during production. Furthermore, with the rise of electric and hybrid machinery, manufacturers are adapting their designs to accommodate new technologies and improve energy efficiency.

The Future of Bearing Housing Manufacturing

As industries continue to evolve, so too do the demands placed on bearing housing manufacturers. The proliferation of automation, robotics, and the Internet of Things (IoT) is shaping the future of manufacturing. Manufacturers are now tasked with producing housings that not only perform well but also support intelligent systems capable of monitoring and predicting maintenance needs. This shift towards smart technologies is likely to enhance equipment reliability and reduce downtime.

In conclusion, bearing housing manufacturers play a vital role in the mechanical industry, providing essential components that support the smooth operation of machinery across various applications. Their expertise in design, quality, and sustainability ensures that machinery operates efficiently and effectively. As technology progresses, these manufacturers will be at the forefront of innovation, shaping the future of mechanical design and performance. Understanding their importance allows for better equipment management and ultimately contributes to the reliability of the systems we depend on daily.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025