Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Bearing Housing Manufacturer for High-Quality Precision Components and Custom Solutions

Understanding Bearing Housing Manufacturers A Key Component in Mechanical Engineering

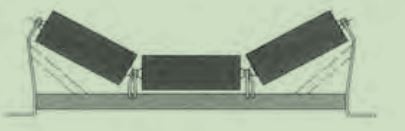

Bearing housings play a pivotal role in various mechanical systems, providing stability, alignment, and protection for bearings used in rotating machinery. As the backbone of many industrial operations, the significance of bearing housing manufacturers cannot be overstated. These specialized manufacturers design and produce housings that not only support bearings but also ensure optimal performance and longevity in various applications.

What is Bearing Housing?

Bearing housing, also known as a bearing pedestal or bearing support, is a component that encases and secures a bearing within a machine. Its primary function is to provide a mount for the bearing, preventing misalignment and housing contamination. The design of bearing housings may vary based on the application, but key features often include rigidity, resistance to wear, and the ability to accommodate thermal expansion.

The Role of Bearing Housing Manufacturers

Bearing housing manufacturers are crucial in the production of these vital components. They work closely with engineering teams to design housings that meet specific requirements tailored to the machinery they will support. This includes considering the loads the bearing will endure, the environmental conditions it will face, and any specific operational demands.

The manufacturing process involves selecting appropriate materials, which could range from cast iron and steel to advanced composites, depending on the application. Manufacturers must also use precise machining techniques to ensure that the housings fit perfectly with the bearings they support. The quality of the bearing housing directly affects the performance, reliability, and lifespan of the entire machinery.

Key Factors to Consider When Choosing a Bearing Housing Manufacturer

bearing housing manufacturer

1. Quality and Standards The reputation of a manufacturer often hinges on the quality of their products. It's essential to choose a company that adheres to industry standards and certifications, ensuring that the bearing housings produced meet safety and performance regulations.

2. Customization Options Not all applications are the same, and the ability to customize bearing housings to fit specific needs is crucial. A good manufacturer should offer a range of customization options, such as different materials, sizes, and design modifications.

3. Technical Support An experienced manufacturer will provide valuable technical support during the selection and installation process. Their expertise can help in choosing the right bearing housing for a particular application, thus enhancing overall operational efficiency.

4. Research and Development Manufacturers that invest in R&D can offer advanced solutions that incorporate the latest technologies. This is especially important in industries like aerospace and automotive, where performance and safety are paramount.

5. Delivery and Logistics Timely delivery is vital to maintaining production schedules. A reliable manufacturer should have a well-established logistics plan to ensure that products reach customers promptly and in good condition.

Conclusion

Bearing housing manufacturers are integral to the success of many industrial processes. Their ability to create high-quality, reliable bearing housings ensures mechanical systems operate smoothly and efficiently. By focusing on quality, customization, and customer support, these manufacturers help engineers and businesses achieve their operational goals.

For those looking to partner with a bearing housing manufacturer, careful consideration of these key factors can lead to a fruitful collaboration. Ultimately, choosing the right partner in this aspect of mechanical engineering can lead to enhanced performance, reduced downtime, and increased productivity in varied applications. As industries continue to evolve and demand more precision and efficiency, the role of bearing housing manufacturers will only become more critical in shaping the future of engineering solutions.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025