Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

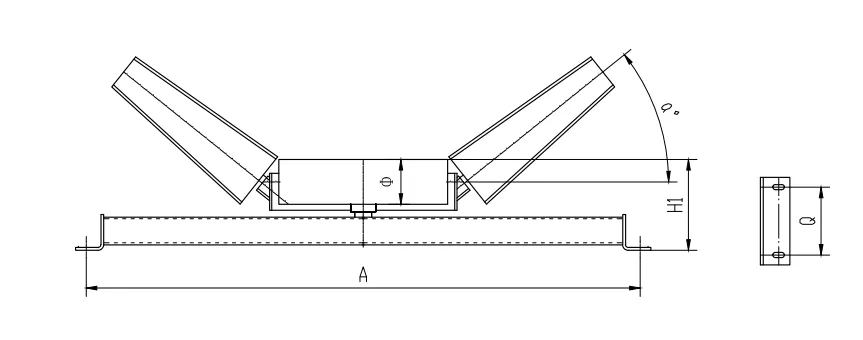

Zulu Design and Specifications of Bearing Housing for Idler Roller Components

Bearing Housing for Idler Roller An Overview

In the world of mechanical engineering, the efficiency and longevity of machinery heavily depend on the precision and integrity of its components. Among these components, the bearing housing for idler rollers plays a crucial role. This article delves into the significance, design, materials, and maintenance considerations associated with bearing housings for idler rollers.

Introduction to Idler Rollers

Idler rollers are widely used in various industries, especially in conveyor systems. Their primary function is to support the movement of belts and ensure the smooth operation of machinery. Unlike drive rollers, idler rollers do not transmit power but instead guide and stabilize the conveyor belts, making them essential for effective material handling.

Importance of Bearing Housings

The bearing housing is a critical component that houses the bearing itself—an element that reduces friction between moving parts and supports radial and axial loads. The design of bearing housings for idler rollers directly impacts the performance and lifespan of the roller. A well-designed bearing housing contributes to reduced wear, noise, and vibration, which enhances the overall efficiency of the conveyor system.

Design Considerations

When designing a bearing housing for idler rollers, several factors must be taken into account

1. Load Capacity The bearing housing must be designed to withstand the static and dynamic loads imposed by the materials being transported. This includes considering the weight of the belt, the idler roller, and any additional loads from the materials being conveyed.

2. Environmental Conditions The operating environment significantly influences the choice of materials and design. For instance, in humid or corrosive environments, materials resistant to rust and deterioration, such as stainless steel or specialized plastics, are advisable.

3. Alignment and Tolerances Proper alignment of the bearing housing is crucial for minimizing wear and tear. High precision in manufacturing tolerances ensures that the roller operates smoothly and efficiently.

4. Lubrication Adequate lubrication supports the bearing and reduces friction. Designers should incorporate features that facilitate easy access for maintenance and lubrication, whether through grease fittings or sealed units.

Material Selection

bearing housing for idler roller

The choice of material for bearing housings is crucial to ensure durability and performance. Common materials include

- Cast Iron Known for its excellent castability and damping properties, cast iron is a popular choice for heavy-duty applications due to its high strength and ability to absorb vibrations.

- Aluminium Lightweight and resistant to corrosion, aluminium is often used in applications where weight reduction is paramount.

- Plastics Engineering plastics, such as nylon and polyurethane, provide excellent corrosion resistance and reduce weight. However, these materials may not be suitable for high-load applications.

- Steel Carbon steel is preferred for its strength and toughness, especially in aggressive environments. It can be treated to enhance corrosion resistance or strength.

Maintenance and Best Practices

To ensure the longevity of bearing housings for idler rollers, regular maintenance is essential. Here are some best practices

1. Regular Inspections Conduct routine inspections to check for signs of wear, misalignment, and damage. Early detection of issues can prevent catastrophic failures.

2. Lubrication Establish a lubrication schedule based on operational hours and environmental conditions. Use the appropriate type and amount of lubricant to avoid excessive friction and overheating.

3. Cleaning Keep the bearing housings clean to prevent dirt and debris from entering the bearings, which can lead to premature failure.

4. Alignment Checks Regularly verify the alignment of the idler rollers and adjust as necessary. Misalignment can lead to increased wear and reduced efficiency.

Conclusion

The bearing housing for idler rollers is a pivotal component in ensuring the smooth operation of various machinery used in industries such as mining, manufacturing, and logistics. Its design, material choice, and maintenance practices are vital for optimizing performance and extending the lifespan of the entire conveyor system. By paying attention to these factors, engineers and maintenance professionals can enhance the reliability and efficiency of idler rollers, ultimately leading to improved operational outcomes and reduced downtime.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025