Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jun . 27, 2024 00:53

Back to list

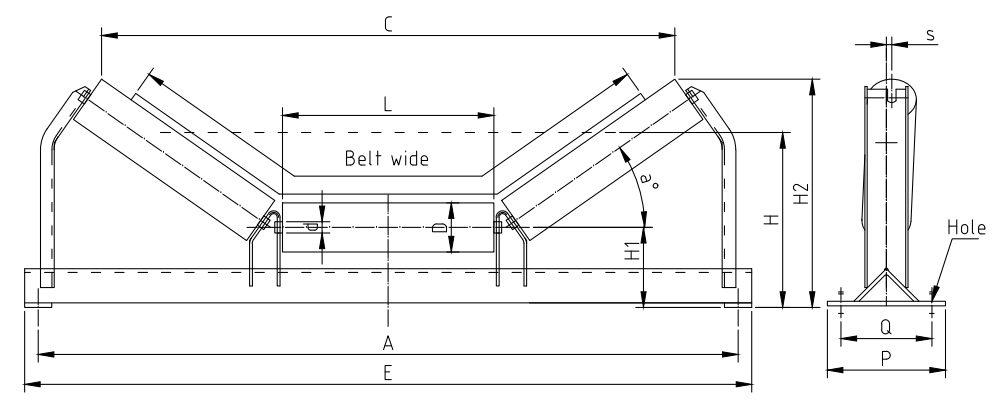

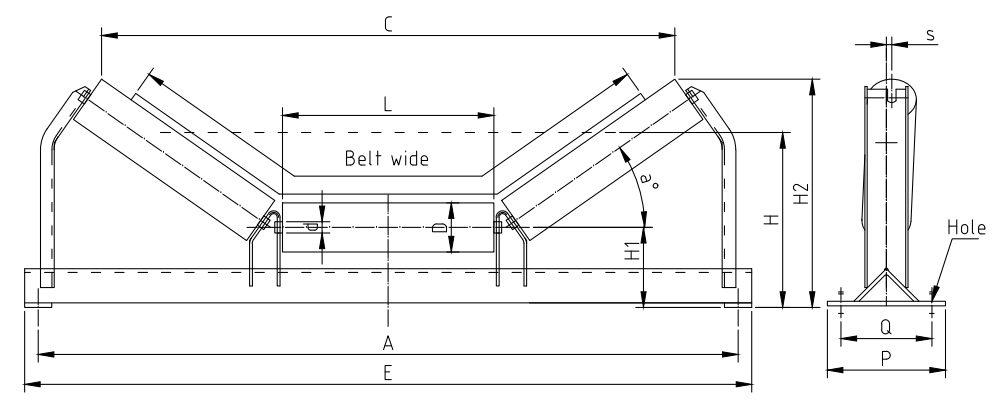

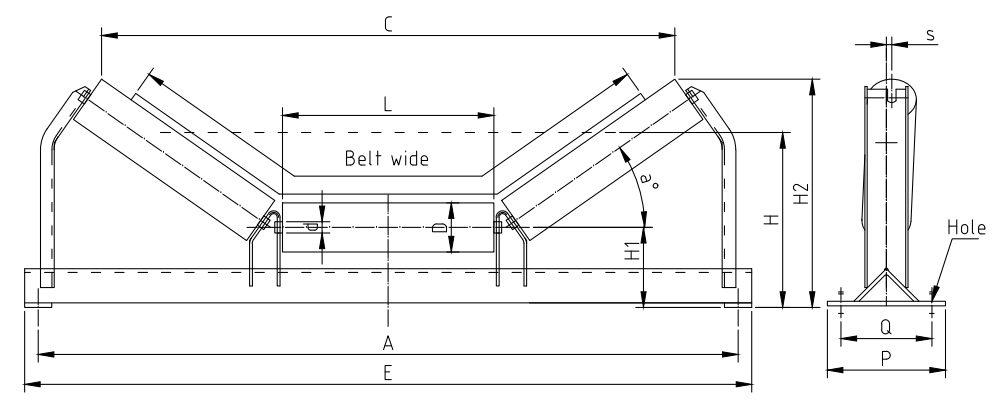

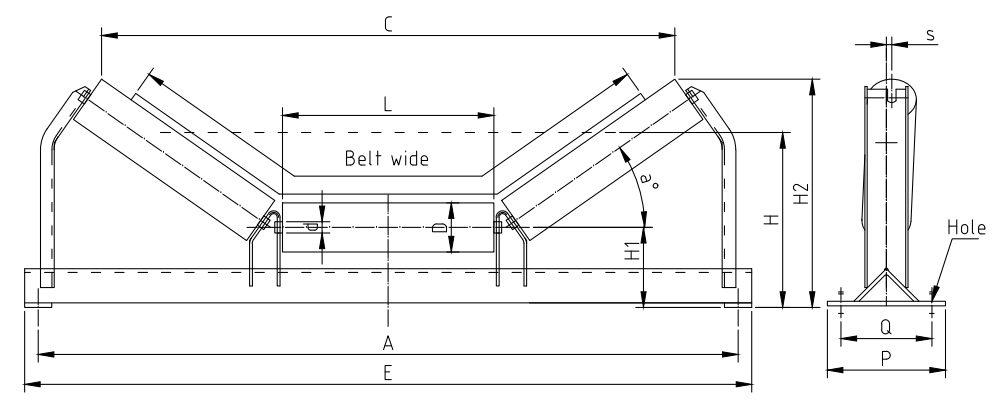

3. Belt Conveyor Roller Selection

Belt Conveyor Roller Types A Comprehensive Guide

Belt conveyors are integral in various industries for transporting materials over long distances efficiently and reliably. These systems consist of a continuous loop of belt that is powered by rollers to move materials from one point to another. The type of roller used in a belt conveyor can significantly impact its performance, longevity, and overall cost-effectiveness. In this article, we will delve into the different types of belt conveyor rollers available and their respective applications.

1. idler rollers These rollers are the most common type and are responsible for supporting the belt and providing the necessary traction to keep it moving. Idler rollers come in various sizes and shapes, including straight, curved, and tapered designs, and can be made from a variety of materials such as steel, aluminum, or plastic.

2. take-up rollers These rollers are used to tension the belt and ensure that it remains in proper alignment. Take-up rollers are typically located at the head or tail of the conveyor system and can be adjusted manually or automatically to accommodate changes in belt length due to wear or changes in material load.

3. return rollers As the name suggests, these rollers guide the belt back to the head of the conveyor system after it has passed over the load zone. Return rollers are usually smaller than idler rollers and are often mounted on brackets or frames to allow for easy adjustment.

4. impact rollers Impact rollers are designed to withstand the force of materials being transported over the belt impact rollers Impact rollers are designed to withstand the force of materials being transported over the belt impact rollers Impact rollers are designed to withstand the force of materials being transported over the belt impact rollers Impact rollers are designed to withstand the force of materials being transported over the belt

impact rollers Impact rollers are designed to withstand the force of materials being transported over the belt impact rollers Impact rollers are designed to withstand the force of materials being transported over the belt belt conveyor roller types. They are typically made from high-strength materials such as cast iron or alloy steel and are often used in areas where the belt may encounter heavy loads or sharp objects.

5. gravity rollers Gravity rollers rely on the force of gravity to move materials down the conveyor belt. These rollers are commonly used in inclined conveyor systems and can be either horizontal or inclined to control the speed of the belt.

6. pneumatic rollers Pneumatic rollers use compressed air to create a cushion of air between the belt and the roller surface, reducing friction and wear. These rollers are often used in applications where the belt must navigate tight curves or bends.

7. motorized rollers Motorized rollers are powered by electric motors and are used to drive the belt directly. These rollers are commonly used in high-speed conveyor systems and can be either individual units or part of a larger drive system.

In conclusion, selecting the right type of belt conveyor roller is crucial for ensuring the optimal performance and longevity of your conveyor system. By understanding the different types of rollers available and their specific applications, you can make an informed decision that meets your unique needs and requirements.

belt conveyor roller types. They are typically made from high-strength materials such as cast iron or alloy steel and are often used in areas where the belt may encounter heavy loads or sharp objects.

5. gravity rollers Gravity rollers rely on the force of gravity to move materials down the conveyor belt. These rollers are commonly used in inclined conveyor systems and can be either horizontal or inclined to control the speed of the belt.

6. pneumatic rollers Pneumatic rollers use compressed air to create a cushion of air between the belt and the roller surface, reducing friction and wear. These rollers are often used in applications where the belt must navigate tight curves or bends.

7. motorized rollers Motorized rollers are powered by electric motors and are used to drive the belt directly. These rollers are commonly used in high-speed conveyor systems and can be either individual units or part of a larger drive system.

In conclusion, selecting the right type of belt conveyor roller is crucial for ensuring the optimal performance and longevity of your conveyor system. By understanding the different types of rollers available and their specific applications, you can make an informed decision that meets your unique needs and requirements.

impact rollers Impact rollers are designed to withstand the force of materials being transported over the belt impact rollers Impact rollers are designed to withstand the force of materials being transported over the belt

impact rollers Impact rollers are designed to withstand the force of materials being transported over the belt impact rollers Impact rollers are designed to withstand the force of materials being transported over the belt belt conveyor roller types. They are typically made from high-strength materials such as cast iron or alloy steel and are often used in areas where the belt may encounter heavy loads or sharp objects.

5. gravity rollers Gravity rollers rely on the force of gravity to move materials down the conveyor belt. These rollers are commonly used in inclined conveyor systems and can be either horizontal or inclined to control the speed of the belt.

6. pneumatic rollers Pneumatic rollers use compressed air to create a cushion of air between the belt and the roller surface, reducing friction and wear. These rollers are often used in applications where the belt must navigate tight curves or bends.

7. motorized rollers Motorized rollers are powered by electric motors and are used to drive the belt directly. These rollers are commonly used in high-speed conveyor systems and can be either individual units or part of a larger drive system.

In conclusion, selecting the right type of belt conveyor roller is crucial for ensuring the optimal performance and longevity of your conveyor system. By understanding the different types of rollers available and their specific applications, you can make an informed decision that meets your unique needs and requirements.

belt conveyor roller types. They are typically made from high-strength materials such as cast iron or alloy steel and are often used in areas where the belt may encounter heavy loads or sharp objects.

5. gravity rollers Gravity rollers rely on the force of gravity to move materials down the conveyor belt. These rollers are commonly used in inclined conveyor systems and can be either horizontal or inclined to control the speed of the belt.

6. pneumatic rollers Pneumatic rollers use compressed air to create a cushion of air between the belt and the roller surface, reducing friction and wear. These rollers are often used in applications where the belt must navigate tight curves or bends.

7. motorized rollers Motorized rollers are powered by electric motors and are used to drive the belt directly. These rollers are commonly used in high-speed conveyor systems and can be either individual units or part of a larger drive system.

In conclusion, selecting the right type of belt conveyor roller is crucial for ensuring the optimal performance and longevity of your conveyor system. By understanding the different types of rollers available and their specific applications, you can make an informed decision that meets your unique needs and requirements. Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS