Why Choose Our Return Idler Bracket for Heavy Conveyors?

What industry folks really mean when they talk about a return idler bracket

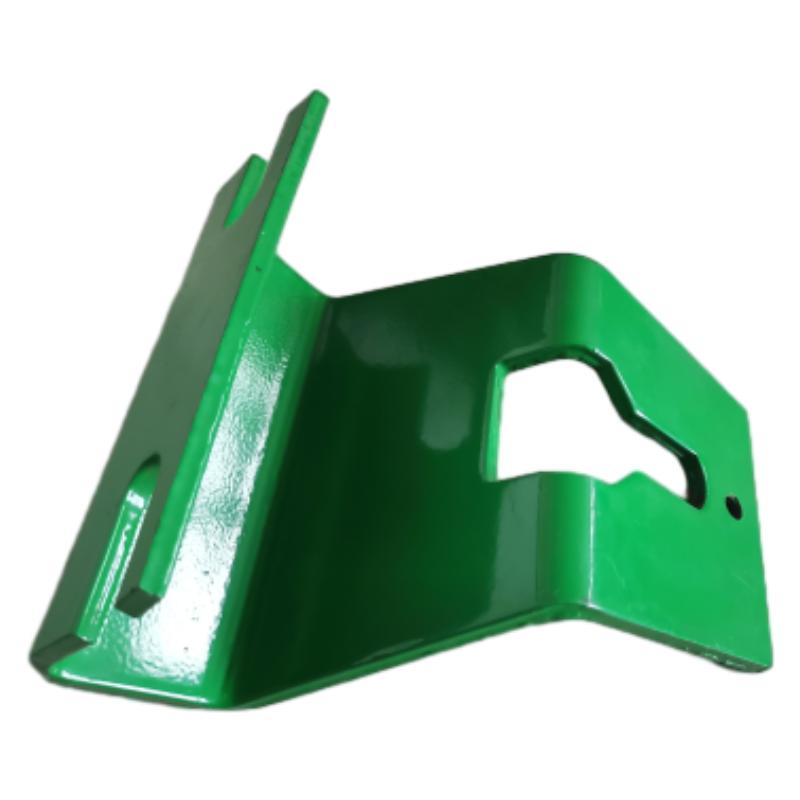

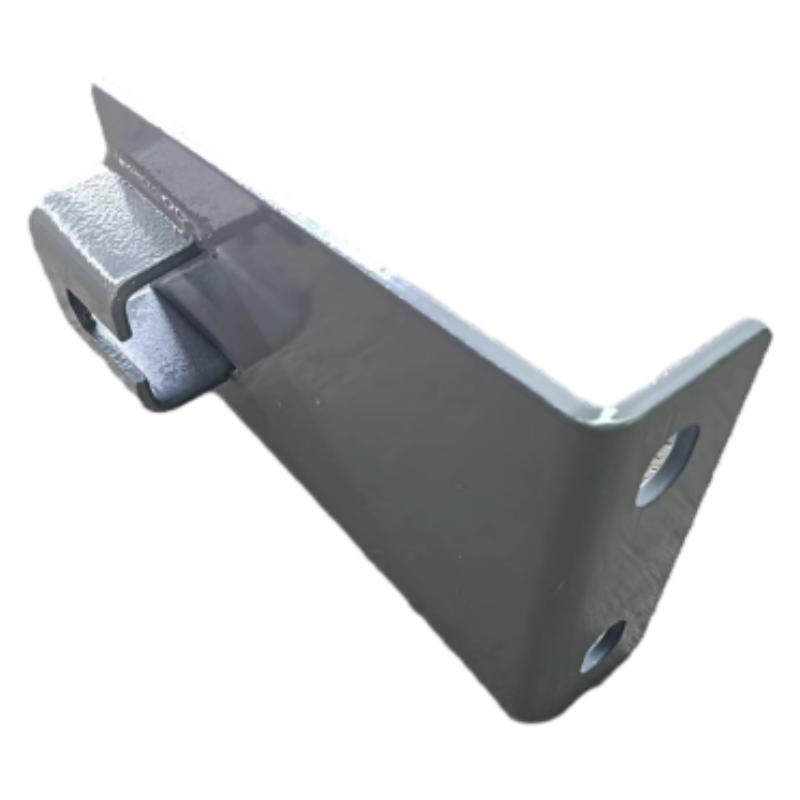

It rarely gets the headline, but in most belt conveyors the quiet hero is the bracket under the return roller. I spent a day at a quarry watching crews swap a dozen of these and, to be honest, you only notice them when they’re wrong. Origin matters too: this model comes out of East Outer Ring Road, Yanshan County, Cangzhou, Hebei—an area that’s been fabricating conveyor hardware for decades. It’s only used on the return side, yes, but the way it holds alignment makes or breaks belt tracking.

What it is, where it fits

The return idler bracket supports the roller on the empty belt side. That’s it—and that’s enough. Proper geometry keeps the belt centered, reduces flap, and avoids those “mystery” edge frays. Many customers say the slotted holes are a lifesaver during changeouts; I agree.

Typical specifications (field-proven, not just brochure promises)

| Parameter | Spec (≈ real-world) |

|---|---|

| Material | Q235 / mild steel; optional Q345 for heavy duty |

| Thickness | 4–6 mm plate, laser cut |

| Finish | Powder coat or hot-dip galvanized (80–120 μm) |

| Belt widths | 500–1600 mm standard; wider on request |

| Hole tolerance | Pitch ±0.5 mm; slot length ±0.8 mm |

| Interchangeability | ISO 1537 main dims; CEMA-compatible roller seats |

| Service life | ≈ 5–10 years in aggregates with proper coating |

Process, testing, and the nerdy stuff

Materials are batch-verified (Mill Certs), then laser cut, CNC-bent, and MIG welded to AWS D1.1. Jigs control squareness so the return idler bracket seats the roller coaxially—sounds fussy, but it prevents belt wandering.

- Shot blasting to Sa 2.5 before coating; DFT checked by ISO 2178 gauge.

- Salt-spray testing 240–500 h (ASTM B117), depending on finish.

- Dimensional audits: slot position Cpk ≥ 1.33; bracket parallelism ≤ 0.6 mm/300 mm.

- Compliance aim: ISO 1537 (idler dims), CEMA 502 alignment guidelines.

Where it’s used

Mining and aggregates, cement plants, ports and terminals, biomass lines, even recycling MRFs. The return idler bracket is only used on the return idlers, but its reliability influences the whole line’s availability.

Vendor snapshot (what buyers actually compare)

| Vendor | Certs | Coating | Lead time | Customization |

|---|---|---|---|---|

| Aohua (Hebei) | ISO 9001, material MTRs | Powder or HDG, 80–120 μm | ≈ 15–25 days | Holes, angles, branding |

| Generic import | Varies | Painted, 40–70 μm | 30–45 days | Limited |

| Local fabricator | Shop QC | Paint per job | 7–21 days | High, cost varies |

Customization tips

Ask for match-drilled holes to your stringer pattern, anti-drop lugs if you service from the walkway side, and welded nameplates. For corrosive sites, the return idler bracket with HDG plus topcoat pays off—surprisingly more than lab data suggests.

Field note: a quick win

A cement line in Southeast Asia swapped 420 brackets during a planned shutdown. Post-change, belt wander incidents fell by ≈18% and cleanup hours dropped noticeably. The maintenance lead told me, “alignment took minutes, not an afternoon.” That’s the return idler bracket doing quiet work.

Why it matters

- Faster alignment thanks to slotted geometry

- Reduced belt edge wear and carryback streaks

- Predictable service intervals; fewer nuisance stops

Citations

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025