TR Seal & Bearing Housings - Durable, Sealed, OEM Supply

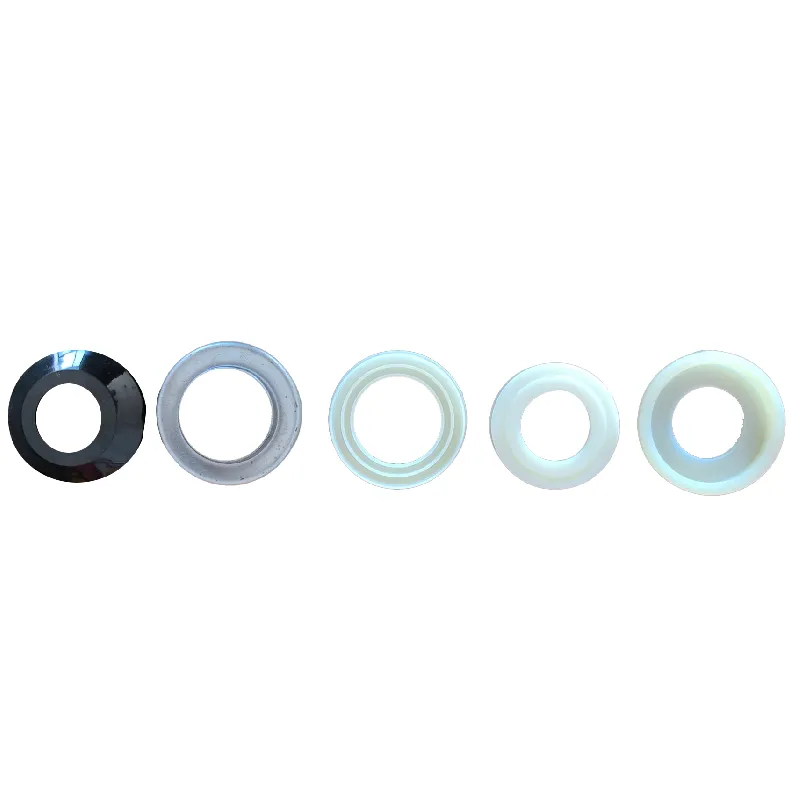

Field Notes on the tr seal: harsh‑environment protection for 6204–6310 bearings

If you run conveyors or rollers anywhere dusty, wet, or frankly unforgiving, you’ve probably wrestled with premature bearing failures. I’ve spent enough time in quarries and cement plants to know: keep the contaminants out and your downtime drops fast. That’s exactly where a tr seal earns its keep.

What it is and why it’s trending

This tr seal line from Cangzhou (East Outer Ring Road, Yanshan County, Hebei, China) combines Nylon/ABS polymers with Q235 steel elements, tailored for common deep-groove bearings: 6204, 6205, 6305, 6306, 6307, 6308, 6309, 6310, and more. The industry shift I’m seeing lately is toward ruggedized labyrinth geometries with tighter press fits, seeking IP-rated dust/water protection without adding much torque drag. In fact, many customers say the latest revisions run cooler and last noticeably longer than the old caps they used to stockpile.

Typical applications

- Mining and aggregate conveyors, transfer points, and feeders

- Cement and bulk materials handling (bad washdown zones)

- Port logistics, grain terminals, and recycling plants

- Outdoor return rollers where a tr seal must resist spray and fines

Product specifications (key data)

| Parameter | Value |

|---|---|

| Materials | Nylon, ABS, Q235 steel |

| Applicable bearings | 6204–6310 series (others on request) |

| Protection | Dustproof, waterproof; target ≈ IP65 in assemblies (real‑world use may vary) |

| Operating temp | -20°C to +90°C continuous (short peaks ≈ +100°C) |

| Typical rpm range | Up to 3,000 rpm for 62/63 series housings |

| Estimated service life | ≈ 15,000–25,000 h in harsh duty; maintenance and sealing geometry affect outcome |

| Certifications | Factory ISO 9001; IP testing per IEC 60529 in typical assemblies |

How it’s made (quick process flow)

Materials: Nylon/ABS pellets and Q235 sheet. Methods: precision injection molding of polymer rings, Q235 stamping and machining, then press-fit assembly of the tr seal with controlled interference. Grease channel and labyrinth features are checked via gauges. Testing standards: ingress checks to IEC 60529 (IP5X/IPX5), salt-spray to ISO 9227 or ASTM B117 for coated steel parts, torque and run-in tests on bearing fixtures, and dimensional checks to drawing tolerances. I guess the secret sauce is consistency; variance here kills longevity.

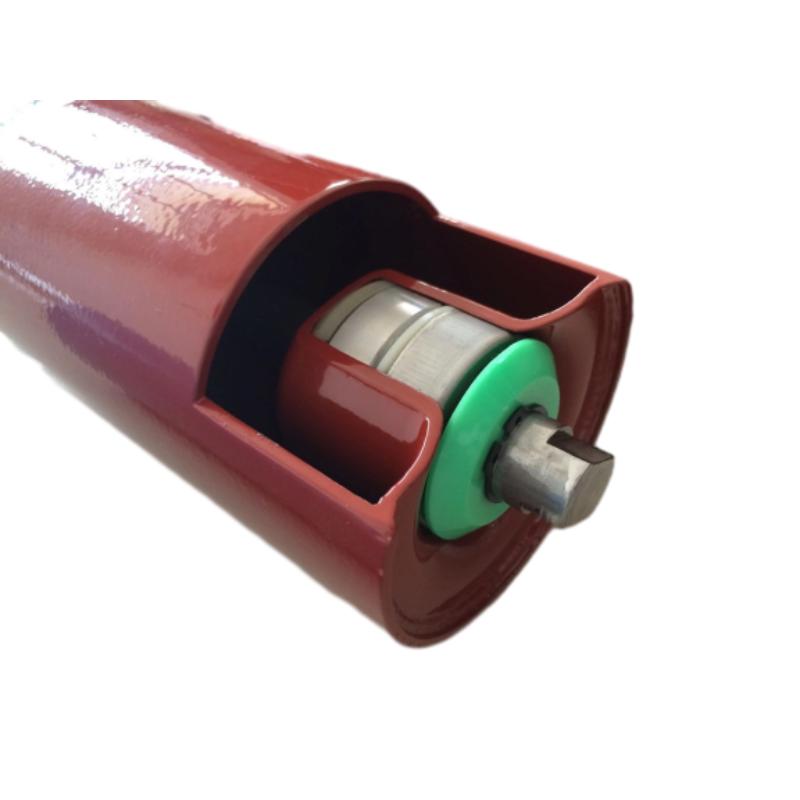

Real-world case

A Hebei limestone quarry swapped legacy caps for this tr seal on 6307 bearings in return rollers. Downtime logs showed mean time between replacements going from 6–8 months to roughly 14 months. Not a lab miracle—just better ingress control during rainy season, according to their maintenance lead.

Vendor snapshot (what buyers compare)

| Vendor | Lead time | Customization | Unit price (≈) | Certs |

|---|---|---|---|---|

| RaoHua (Cangzhou, China) | 10–20 days | Bore/OD, materials, logo | $1.2–$3.8 | ISO 9001; IP tests |

| Local fabricator (regional) | 2–6 weeks | Moderate | $2.5–$5.0 | Varies |

| Global brand | Stock/4–8 weeks | Limited SKUs | $4.0–$8.0 | ISO 9001, traceability |

Buying tips and customization

- Match the tr seal to bearing series and housing depth; ask for a torque curve if energy is critical.

- For saline or fertilizer exposure, request coated steel or full polymer variants plus ISO 9227 test data.

- Consider laser-marked lot traceability and grease purge paths if you over-grease (we all do sometimes).

Test data snapshot: IP5X dust test passed on assembled roller fixtures; water jet per IPX5 with no visible ingress; 96 h neutral salt-spray on coated Q235 with no red rust (representative sample; your environment may differ).

Standards and references

- IEC 60529: Degrees of protection provided by enclosures (IP Code).

- ISO 9227: Corrosion tests in artificial atmospheres—Salt spray tests; ASTM B117 comparable practice.

- ISO 281: Rolling bearings—Dynamic load ratings and rating life (context for bearing life alongside sealing).

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025