Jan . 16, 2025 03:48

Back to list

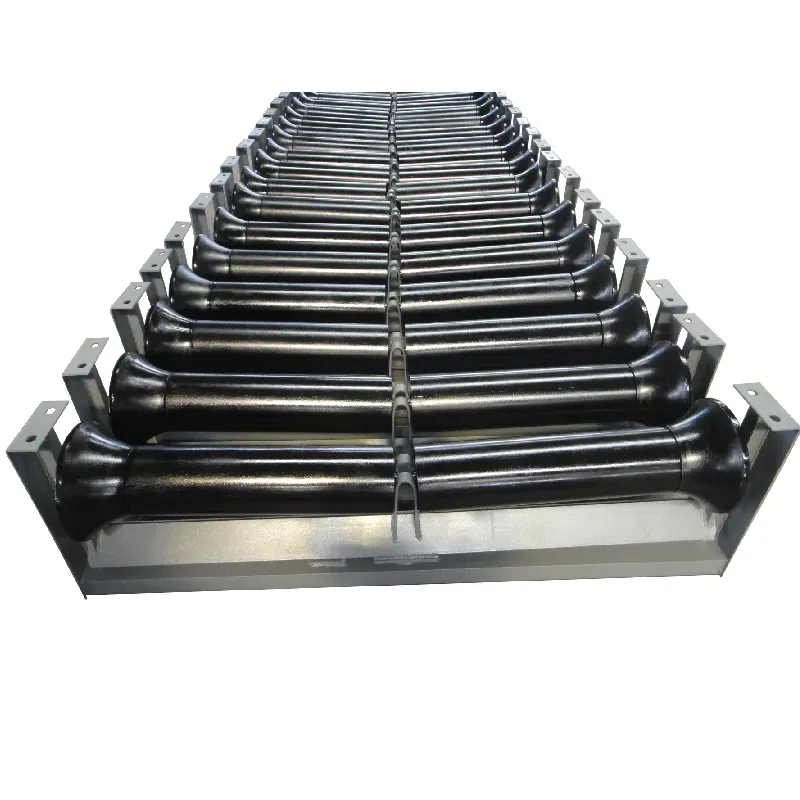

v belt drive pulley

Rubber drive pulleys are essential components in many industrial applications, playing a crucial role in power transmission systems. With their versatility and adaptability, these components are central to enhancing the efficiency of machinery across various sectors. Over the years, my experience and expertise working with rubber drive pulleys have shown how crucial they are in multiple applications, from conveyor systems to automation technologies.

A trusted manufacturer of these pulleys often provides customizable solutions to cater to specific industrial needs. They offer variations in the durometer of the rubber, surface texture, and crown or flat-face designs, each serving different purposes depending on load requirements and belt material. Expertise in designing these variations ensures that industries have tailored solutions that address specific challenges, thereby increasing machinery uptime and reducing maintenance costs. Professional assessment and testing are paramount to ensure the optimal performance of rubber drive pulleys. Accreditation from reputable industry standards and thorough scrutiny through performance assessments during the production phase ensure the credibility and authoritative standing of these components. Leading manufacturers employ rigorous quality control measures, including dynamic balancing and vibration analysis, reinforcing trust and dependability in their offerings. In conclusion, the intricate role that rubber drive pulleys play in mechanical and industrial systems cannot be understated. Their expert design, quality assurance, and customizability make them invaluable to sectors requiring precision and efficiency. As industries evolve with more complex mechanical demands, the reliance on rubber drive pulleys will undoubtedly continue to grow, backed by their proven expertise, authority, and trustworthy performance in diverse applications.

A trusted manufacturer of these pulleys often provides customizable solutions to cater to specific industrial needs. They offer variations in the durometer of the rubber, surface texture, and crown or flat-face designs, each serving different purposes depending on load requirements and belt material. Expertise in designing these variations ensures that industries have tailored solutions that address specific challenges, thereby increasing machinery uptime and reducing maintenance costs. Professional assessment and testing are paramount to ensure the optimal performance of rubber drive pulleys. Accreditation from reputable industry standards and thorough scrutiny through performance assessments during the production phase ensure the credibility and authoritative standing of these components. Leading manufacturers employ rigorous quality control measures, including dynamic balancing and vibration analysis, reinforcing trust and dependability in their offerings. In conclusion, the intricate role that rubber drive pulleys play in mechanical and industrial systems cannot be understated. Their expert design, quality assurance, and customizability make them invaluable to sectors requiring precision and efficiency. As industries evolve with more complex mechanical demands, the reliance on rubber drive pulleys will undoubtedly continue to grow, backed by their proven expertise, authority, and trustworthy performance in diverse applications.

Next:

Latest news

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025

OUR PRODUCTS