pressed steel bearing housing

The Importance of Pressed Steel Bearing Housings in Modern Engineering

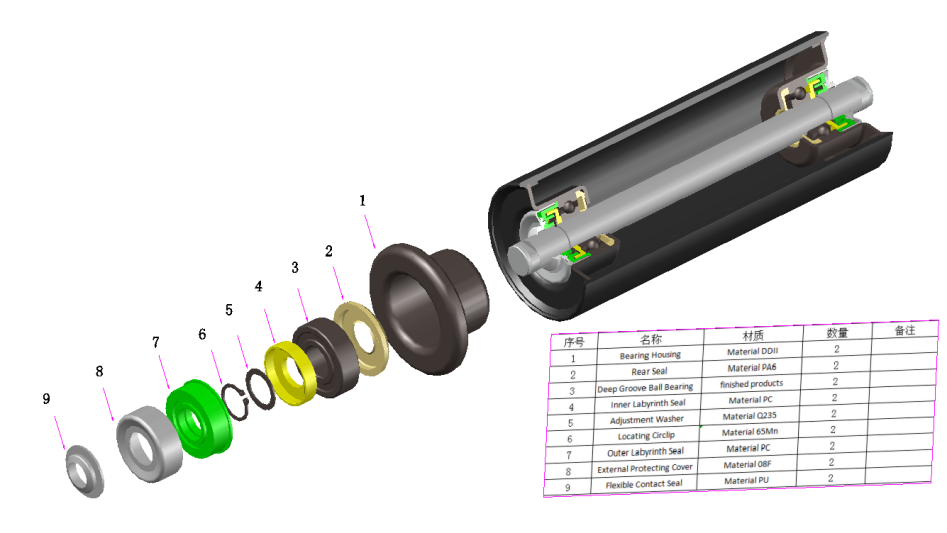

Pressed steel bearing housings play a crucial role in modern engineering, particularly in the design and functionality of various machinery and mechanical systems. These housings provide a robust and reliable framework for supporting bearings, which are critical components in reducing friction and facilitating smooth rotational or linear movement in machines. The choice of material and design in bearing housings can significantly influence the overall performance, longevity, and efficiency of mechanical systems.

One of the primary advantages of using pressed steel for bearing housings is its excellent strength-to-weight ratio. Steel is inherently strong, which allows for the creation of more compact designs that can withstand high loads without adding unnecessary weight to the machinery. This characteristic is especially beneficial in applications such as automotive and aerospace engineering, where every ounce matters. Moreover, the pressed design process allows for precision manufacturing, ensuring that housings fit perfectly with the associated bearings.

In addition to strength, pressed steel bearing housings are resistant to wear and corrosion, making them suitable for a wide range of environmental conditions. This durability is vital in industrial applications where machines are often exposed to harsh conditions, such as humidity, dust, and temperature fluctuations. By choosing a housing made from pressed steel, engineers can significantly enhance the reliability and operational lifespan of their machinery.

pressed steel bearing housing

The cost-effectiveness of pressed steel bearing housings is another compelling reason for their widespread use. The manufacturing process involves using sheet steel that is molded into shape, which reduces material waste and lowers production costs. This cost efficiency does not compromise quality; instead, it allows manufacturers to provide more competitive pricing while maintaining high standards of performance and safety.

Furthermore, advancements in technology are driving innovations in the design of pressed steel bearing housings. Modern techniques such as computer-aided design (CAD) enable the creation of complex and optimized shapes that enhance load distribution and reduce stress concentrations, lowering the risk of failure. These innovations not only improve performance but also respond to the stringent demands of contemporary applications.

In conclusion, pressed steel bearing housings are indispensable components in various mechanical systems, offering a unique blend of strength, durability, cost-effectiveness, and modern design capabilities. As industries continue to evolve and seek more efficient solutions, the role of these components will only grow in importance. Engineers and manufacturers must continue to explore and optimize the use of pressed steel in bearing housings to meet the ever-increasing demands of modern technology and engineering challenges.

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025