Premium Idler Rollers for Belt Conveyors: Durable & Efficient

The China International Industry Fair (CIIF) stands as a monumental event, a vibrant crucible where the future of industrial technology is forged and showcased. For B2B decision-makers worldwide, it’s a critical destination for discovering groundbreaking innovations in material handling and mechanical components. CIIF serves as a leading platform, offering a window into high-precision solutions for optimizing industrial operations. It's where manufacturers unveil their latest advancements, aiming to expand international distribution networks and secure new projects for sophisticated material transport systems, particularly in the realm of conveyor components like idler rollers for belt conveyors. This fair offers unparalleled value for the mechanical industry, spotlighting the ingenuity driving efficiency and productivity across sectors.

Industry Trend Spotlight: The Evolution of Material Handling

In today's rapidly evolving industrial landscape, the demand for sophisticated material handling solutions is surging. We are witnessing an increasing global attention on automated and integrated production lines, which necessitate reliable and high-performance components. Smart controls, often integrating PLC/CNC systems, are no longer a luxury but a necessity for enhancing the precision and efficiency of conveyor systems. Imagine idler rollers equipped with intelligent sensors for real-time monitoring – that's the direction we're heading.

Modular designs are gaining traction, allowing for flexible customization of conveyor configurations to adapt to diverse operational needs. Furthermore, the advent of remote diagnostics and IoT-enabled predictive maintenance is revolutionizing how we manage assets like steel idler rollers, drastically reducing downtime and maintenance costs. Manufacturers are also heavily invested in the development of components capable of processing new advanced materials, focusing on weight reduction, increased strength, and enhanced durability – crucial for handling abrasive or heavy loads with specific idler roller types.

Market Data & Key Trends:

The global conveyor systems market, including critical components like idler rollers for belt conveyors, is projected for steady growth. This expansion is primarily driven by increasing demand from vital sectors such as mining, logistics, general manufacturing (especially automotive and food processing), and construction. Key trends fueling this growth include:

- The persistent push for automation to combat rising labor costs and enhance operational efficiency.

- A growing demand for higher precision and efficiency in material transport, ensuring consistent product quality and throughput.

- Significant growth opportunities in emerging markets, where industrialization is accelerating.

However, the industry also faces challenges, including raw material price volatility, supply chain disruptions, and intense competition, making innovation and strategic partnerships more vital than ever.

Emerging Focus Areas:

- Industry 4.0 Integration: Seamless connectivity and data exchange in material handling systems.

- Advanced Automation: Robotics and AI-driven solutions for conveyor lines, optimizing everything from loading to sorting.

- Energy-Efficient Transport: Innovations in motor technologies, lubrication, and friction reduction for idler rollers with bearings.

- Smart Predictive Maintenance: IoT sensors on idler roller assemblies providing early warnings for wear and tear.

- Sustainable Material Handling: Utilizing eco-friendly materials and processes in manufacturing components like rubber idler rollers.

Profiles of Leading Manufacturers at CIIF

CIIF provides a unique opportunity to engage with global leaders in industrial equipment. Among them, several Chinese manufacturers are carving out a significant niche with their innovative solutions and commitment to quality.

Yanshan Aohua Machinery Equipment Manufacture Limited Company

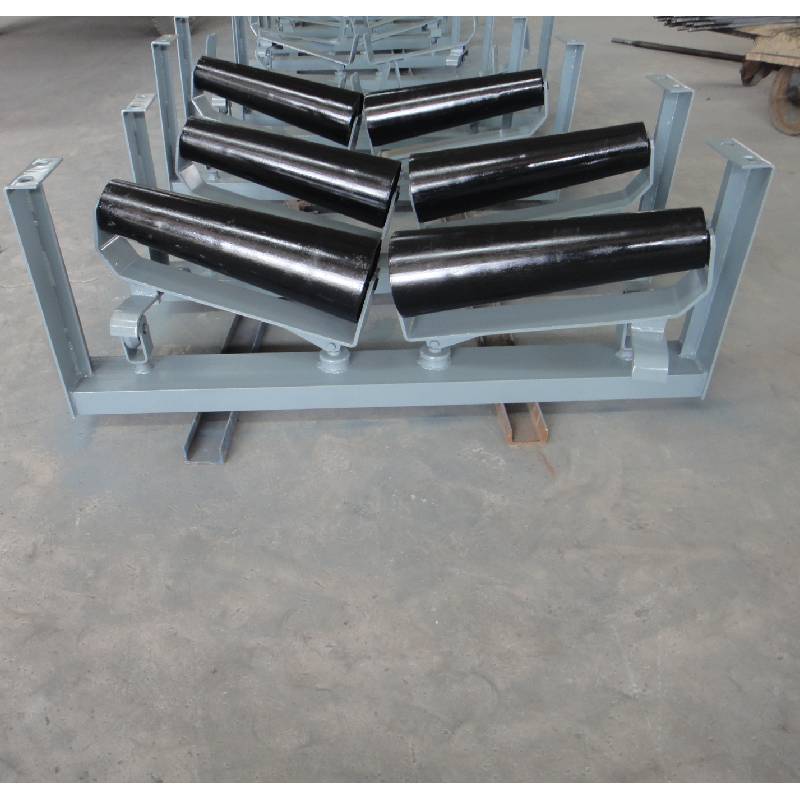

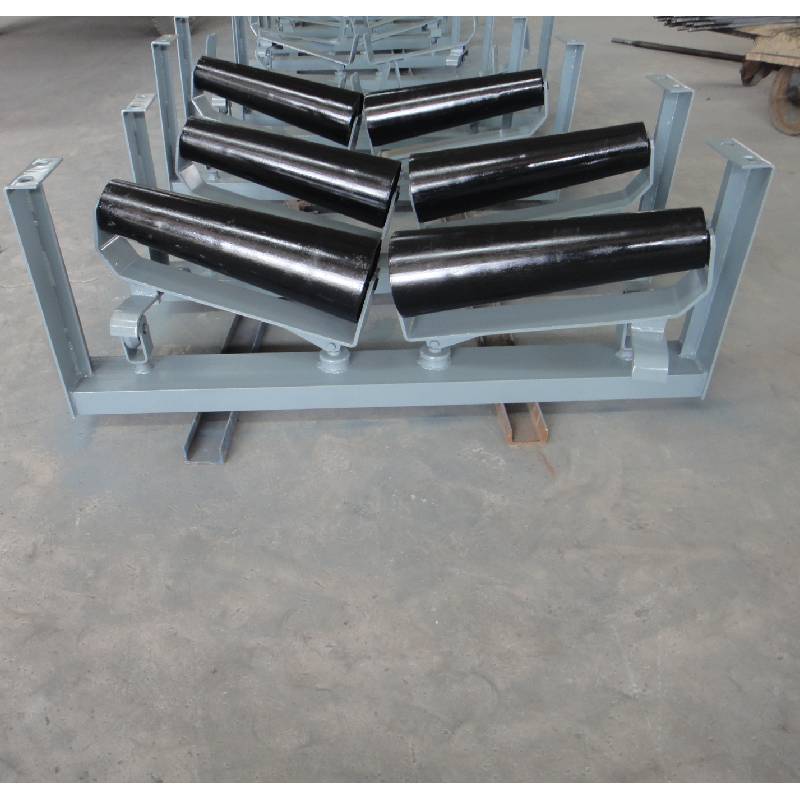

Yanshan Aohua Machinery Equipment Manufacture Limited Company stands out as a leading specialist in high-quality conveyor components. Their core expertise lies in manufacturing a comprehensive range of idler rollers, essential for efficient and reliable belt conveyor systems. This includes specialized products like taper aligning idlers, designed to keep conveyor belts running true and prevent costly spillage.

They boast established manufacturing capabilities, enabling them to provide highly customized solutions tailored to the unique demands of various industries, from heavy mining to precise logistics. Yanshan Aohua is known for its competitive pricing strategies without compromising on the robust engineering and durability of their steel idler rollers, rubber idler rollers, and comprehensive idler roller assemblies. Their strong focus on engineering excellence and dedicated after-sales support makes them a reliable partner for integrating complex industrial equipment and ensuring long-term operational success for their clients. Whether you need standard idlers and rollers or specialized training idlers to enhance belt tracking, Yanshan Aohua offers a solution.

Other Noteworthy Industrial Equipment Manufacturers

While Yanshan Aohua excels in conveyor components, the broader industrial machinery landscape at CIIF is populated by giants whose operations and products often interact with or necessitate advanced material handling solutions. These companies represent the pinnacle of engineering in various heavy industries, relying on robust, efficient, and precise mechanical components throughout their operations:

- SMS Group: A global leader in plant and machinery for the steel and non-ferrous metals industry, known for its extensive range of innovative solutions from raw material processing to finished products. Their massive operations demand unparalleled efficiency in material movement.

- Fives Group: An international engineering group that designs and supplies machines, process equipment, and production lines for a diverse range of industries, including aluminum, steel, glass, and logistics. Their integrated solutions often feature advanced conveyor technologies.

- Danieli: One of the world's foremost suppliers of plant and equipment to the metal industry, offering innovative and reliable solutions from ore to finished products. High-performance material handling is critical to their large-scale plants.

- Schuler Group: A technological and global market leader in forming technology, supplying state-of-the-art presses, automation solutions, dies, process know-how, and services for the entire metalworking industry. Efficient internal logistics are paramount for their high-speed production lines.

- Wuxi Fuda Machinery Co., Ltd.: A prominent Chinese manufacturer with diverse machinery offerings, often serving as a key supplier for various industrial equipment needs, contributing to the robust manufacturing ecosystem that supports material handling innovations.

Market Outlook & Opportunities in Material Handling

The future of material handling is bright, driven by relentless innovation and evolving buyer demands. Upcoming trends indicate a strong emphasis on smart, connected, and sustainable solutions. Buyers are increasingly looking for systems that not only move materials efficiently but also provide real-time data, reduce energy consumption, and minimize environmental impact. This creates significant opportunities for manufacturers of idler rollers and other conveyor components that can meet these advanced requirements.

Key opportunities include:

- Advanced Automation: Integrating idler rollers with bearings that offer low friction and high precision, compatible with automated systems.

- Smart Manufacturing: Developing idler roller assemblies with embedded sensors for condition monitoring, allowing for predictive maintenance and extended lifespan.

- Sustainability: Designing rubber idler rollers and other components from recycled or recyclable materials, and focusing on energy-efficient designs.

- Customization & Modularity: The ability to quickly adapt conveyor systems with different idler roller types to specific operational challenges.

Buyer & Business Takeaways: Partnering for Future-Proof Success

For B2B decision-makers, understanding these trends and selecting the right partners is paramount. Investing in high-quality idler rollers for belt conveyors and other critical mechanical components isn't just about operational efficiency; it's about securing a competitive edge, ensuring safety, and extending the lifespan of your entire material handling infrastructure.

Why Invest in High-Quality Idler Rollers?

- Reduced Downtime: Superior idler rollers, like steel idler rollers designed for durability, minimize unexpected failures.

- Lower Operating Costs: Efficient idler rollers with bearings reduce friction, leading to less energy consumption and lower maintenance.

- Enhanced Belt Lifespan: Properly functioning idler rollers, including training idlers and taper aligning idlers, prevent belt misalignment and premature wear.

- Improved Safety: Reliable idler roller assemblies contribute to a safer working environment by preventing system failures.

Tips for Adopting or Partnering with Chinese Manufacturers:

- Due Diligence: Thoroughly research potential partners, checking their certifications, quality control processes, and client testimonials.

- Clear Specifications: Provide precise technical specifications for your idler rollers, including materials, dimensions, and performance requirements.

- Focus on R&D: Prioritize manufacturers like Yanshan Aohua who demonstrate ongoing investment in research and development for new idler roller types and technologies.

- Long-Term Relationships: Seek partners interested in long-term collaboration, offering consistent quality and responsive after-sales support for your idlers and rollers.

Future-Proof Strategies:

- Embrace Digitalization: Integrate IoT-enabled idler rollers for real-time monitoring and predictive maintenance.

- Prioritize Modularity: Choose conveyor systems and components that allow for easy upgrades and reconfigurations.

- Sustainable Sourcing: Opt for manufacturers committed to environmentally responsible production and materials, such as those producing durable rubber idler rollers.

Conclusion: The Road Ahead for Material Handling

The China International Industry Fair (CIIF) continues to be an indispensable event, shaping the global mechanical and material handling market. It's where innovation in components like idler rollers for belt conveyors meets industrial demand, driving advancements in efficiency, automation, and sustainability. For B2B decision-makers, CIIF offers a unique opportunity to connect with leading manufacturers, explore cutting-edge solutions, and forge partnerships that will define the future of their operations. Companies like Yanshan Aohua are at the forefront, providing the reliable, high-performance idler rollers that are the backbone of modern industrial transport.

To explore Yanshan Aohua's innovative taper aligning idlers and other premium conveyor components, visit our product page today!

The China International Industry Fair (CIIF) stands as a monumental event, a vibrant crucible where the future of industrial technology is forged and showcased. For B2B decision-makers worldwide, it’s a critical destination for discovering groundbreaking innovations in material handling and mechanical components. CIIF serves as a leading platform, offering a window into high-precision solutions for optimizing industrial operations. It's where manufacturers unveil their latest advancements, aiming to expand international distribution networks and secure new projects for sophisticated material transport systems, particularly in the realm of conveyor components like idler rollers for belt conveyors. This fair offers unparalleled value for the mechanical industry, spotlighting the ingenuity driving efficiency and productivity across sectors.

Industry Trend Spotlight: The Evolution of Material Handling

In today's rapidly evolving industrial landscape, the demand for sophisticated material handling solutions is surging. We are witnessing an increasing global attention on automated and integrated production lines, which necessitate reliable and high-performance components. Smart controls, often integrating PLC/CNC systems, are no longer a luxury but a necessity for enhancing the precision and efficiency of conveyor systems. Imagine idler rollers equipped with intelligent sensors for real-time monitoring – that's the direction we're heading.

Modular designs are gaining traction, allowing for flexible customization of conveyor configurations to adapt to diverse operational needs. Furthermore, the advent of remote diagnostics and IoT-enabled predictive maintenance is revolutionizing how we manage assets like steel idler rollers, drastically reducing downtime and maintenance costs. Manufacturers are also heavily invested in the development of components capable of processing new advanced materials, focusing on weight reduction, increased strength, and enhanced durability – crucial for handling abrasive or heavy loads with specific idler roller types.

Market Data & Key Trends:

The global conveyor systems market, including critical components like idler rollers for belt conveyors, is projected for steady growth. This expansion is primarily driven by increasing demand from vital sectors such as mining, logistics, general manufacturing (especially automotive and food processing), and construction. Key trends fueling this growth include:

- The persistent push for automation to combat rising labor costs and enhance operational efficiency.

- A growing demand for higher precision and efficiency in material transport, ensuring consistent product quality and throughput.

- Significant growth opportunities in emerging markets, where industrialization is accelerating.

However, the industry also faces challenges, including raw material price volatility, supply chain disruptions, and intense competition, making innovation and strategic partnerships more vital than ever.

Emerging Focus Areas:

- Industry 4.0 Integration: Seamless connectivity and data exchange in material handling systems.

- Advanced Automation: Robotics and AI-driven solutions for conveyor lines, optimizing everything from loading to sorting.

- Energy-Efficient Transport: Innovations in motor technologies, lubrication, and friction reduction for idler rollers with bearings.

- Smart Predictive Maintenance: IoT sensors on idler roller assemblies providing early warnings for wear and tear.

- Sustainable Material Handling: Utilizing eco-friendly materials and processes in manufacturing components like rubber idler rollers.

Profiles of Leading Manufacturers at CIIF

CIIF provides a unique opportunity to engage with global leaders in industrial equipment. Among them, several Chinese manufacturers are carving out a significant niche with their innovative solutions and commitment to quality.

Yanshan Aohua Machinery Equipment Manufacture Limited Company

Yanshan Aohua Machinery Equipment Manufacture Limited Company stands out as a leading specialist in high-quality conveyor components. Their core expertise lies in manufacturing a comprehensive range of idler rollers, essential for efficient and reliable belt conveyor systems. This includes specialized products like taper aligning idlers, designed to keep conveyor belts running true and prevent costly spillage.

They boast established manufacturing capabilities, enabling them to provide highly customized solutions tailored to the unique demands of various industries, from heavy mining to precise logistics. Yanshan Aohua is known for its competitive pricing strategies without compromising on the robust engineering and durability of their steel idler rollers, rubber idler rollers, and comprehensive idler roller assemblies. Their strong focus on engineering excellence and dedicated after-sales support makes them a reliable partner for integrating complex industrial equipment and ensuring long-term operational success for their clients. Whether you need standard idlers and rollers or specialized training idlers to enhance belt tracking, Yanshan Aohua offers a solution.

Other Noteworthy Industrial Equipment Manufacturers

While Yanshan Aohua excels in conveyor components, the broader industrial machinery landscape at CIIF is populated by giants whose operations and products often interact with or necessitate advanced material handling solutions. These companies represent the pinnacle of engineering in various heavy industries, relying on robust, efficient, and precise mechanical components throughout their operations:

- SMS Group: A global leader in plant and machinery for the steel and non-ferrous metals industry, known for its extensive range of innovative solutions from raw material processing to finished products. Their massive operations demand unparalleled efficiency in material movement.

- Fives Group: An international engineering group that designs and supplies machines, process equipment, and production lines for a diverse range of industries, including aluminum, steel, glass, and logistics. Their integrated solutions often feature advanced conveyor technologies.

- Danieli: One of the world's foremost suppliers of plant and equipment to the metal industry, offering innovative and reliable solutions from ore to finished products. High-performance material handling is critical to their large-scale plants.

- Schuler Group: A technological and global market leader in forming technology, supplying state-of-the-art presses, automation solutions, dies, process know-how, and services for the entire metalworking industry. Efficient internal logistics are paramount for their high-speed production lines.

- Wuxi Fuda Machinery Co., Ltd.: A prominent Chinese manufacturer with diverse machinery offerings, often serving as a key supplier for various industrial equipment needs, contributing to the robust manufacturing ecosystem that supports material handling innovations.

Market Outlook & Opportunities in Material Handling

The future of material handling is bright, driven by relentless innovation and evolving buyer demands. Upcoming trends indicate a strong emphasis on smart, connected, and sustainable solutions. Buyers are increasingly looking for systems that not only move materials efficiently but also provide real-time data, reduce energy consumption, and minimize environmental impact. This creates significant opportunities for manufacturers of idler rollers and other conveyor components that can meet these advanced requirements.

Key opportunities include:

- Advanced Automation: Integrating idler rollers with bearings that offer low friction and high precision, compatible with automated systems.

- Smart Manufacturing: Developing idler roller assemblies with embedded sensors for condition monitoring, allowing for predictive maintenance and extended lifespan.

- Sustainability: Designing rubber idler rollers and other components from recycled or recyclable materials, and focusing on energy-efficient designs.

- Customization & Modularity: The ability to quickly adapt conveyor systems with different idler roller types to specific operational challenges.

Buyer & Business Takeaways: Partnering for Future-Proof Success

For B2B decision-makers, understanding these trends and selecting the right partners is paramount. Investing in high-quality idler rollers for belt conveyors and other critical mechanical components isn't just about operational efficiency; it's about securing a competitive edge, ensuring safety, and extending the lifespan of your entire material handling infrastructure.

Why Invest in High-Quality Idler Rollers?

- Reduced Downtime: Superior idler rollers, like steel idler rollers designed for durability, minimize unexpected failures.

- Lower Operating Costs: Efficient idler rollers with bearings reduce friction, leading to less energy consumption and lower maintenance.

- Enhanced Belt Lifespan: Properly functioning idler rollers, including training idlers and taper aligning idlers, prevent belt misalignment and premature wear.

- Improved Safety: Reliable idler roller assemblies contribute to a safer working environment by preventing system failures.

Tips for Adopting or Partnering with Chinese Manufacturers:

- Due Diligence: Thoroughly research potential partners, checking their certifications, quality control processes, and client testimonials.

- Clear Specifications: Provide precise technical specifications for your idler rollers, including materials, dimensions, and performance requirements.

- Focus on R&D: Prioritize manufacturers like Yanshan Aohua who demonstrate ongoing investment in research and development for new idler roller types and technologies.

- Long-Term Relationships: Seek partners interested in long-term collaboration, offering consistent quality and responsive after-sales support for your idlers and rollers.

Future-Proof Strategies:

- Embrace Digitalization: Integrate IoT-enabled idler rollers for real-time monitoring and predictive maintenance.

- Prioritize Modularity: Choose conveyor systems and components that allow for easy upgrades and reconfigurations.

- Sustainable Sourcing: Opt for manufacturers committed to environmentally responsible production and materials, such as those producing durable rubber idler rollers.

Conclusion: The Road Ahead for Material Handling

The China International Industry Fair (CIIF) continues to be an indispensable event, shaping the global mechanical and material handling market. It's where innovation in components like idler rollers for belt conveyors meets industrial demand, driving advancements in efficiency, automation, and sustainability. For B2B decision-makers, CIIF offers a unique opportunity to connect with leading manufacturers, explore cutting-edge solutions, and forge partnerships that will define the future of their operations. Companies like Yanshan Aohua are at the forefront, providing the reliable, high-performance idler rollers that are the backbone of modern industrial transport.

To explore Yanshan Aohua's innovative taper aligning idlers and other premium conveyor components, visit our product page today!

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025