High-Quality Polyurethane Rollers for Industrial Applications

The Importance of Polyurethane Rollers in Modern Industry

In the realm of industrial applications, polyurethane rollers have emerged as a critical component due to their versatile properties and superior performance. These specialized rollers are made from polyurethane, a polymer known for its durability, flexibility, and resistance to wear and tear. This article explores the significance of polyurethane rollers, their advantages, and their applications across various sectors.

One of the most notable features of polyurethane rollers is their exceptional durability. Unlike traditional rubber rollers, polyurethane offers enhanced resistance to abrasion, which is crucial in environments where machinery is consistently subjected to heavy loads and friction. This longevity translates into reduced downtime and maintenance costs, allowing industries to operate more efficiently.

The flexibility of polyurethane also plays a vital role in its widespread adoption. These rollers can be manufactured in various hardness levels, making them suitable for a wide range of applications. For instance, softer rollers are ideal for delicate processes, such as handling lightweight materials or sensitive products, where gentle contact is necessary. Conversely, harder rollers can manage heavier loads and provide the required grip for demanding environments, like manufacturing and material handling.

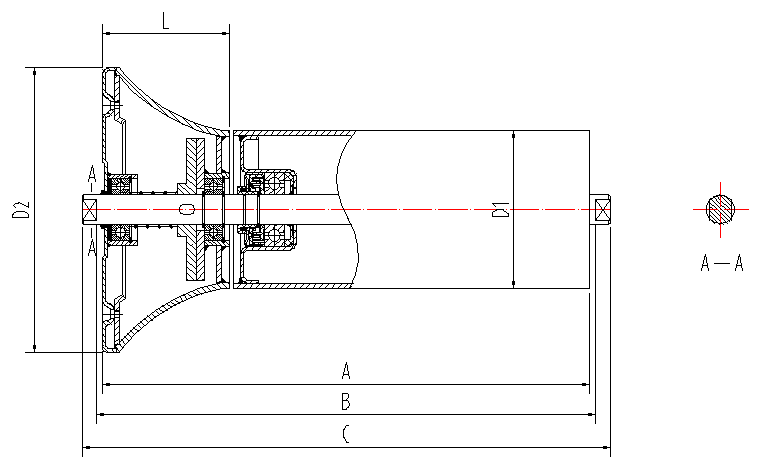

polyurethane roller

Moreover, polyurethane rollers exhibit excellent chemical resistance

. They can withstand exposure to oils, greases, and various solvents, which makes them ideal for use in industries such as food processing, pharmaceuticals, and automotive. This property ensures that the rollers maintain their integrity and performance even in harsh working conditions.In the realm of manufacturing, polyurethane rollers are used in various applications, including conveyor systems, printing machines, and packaging equipment. Their ability to produce a smooth surface finish enhances the quality of the products being processed. Additionally, the noise-dampening characteristics of polyurethane lead to quieter operations, which is a significant advantage in settings where noise reduction is a priority.

The innovation in manufacturing processes has also led to the development of custom polyurethane rollers. These rollers can be designed to meet specific dimensional and performance criteria, making them adaptable to unique machinery and operational needs. Customization allows industries to achieve optimal performance, ensuring that their equipment runs smoothly and efficiently.

In conclusion, polyurethane rollers have become an essential resource in modern industrial operations. Their durability, flexibility, chemical resistance, and adaptability make them invaluable across various sectors. As industries continue to evolve, the demand for high-performance materials like polyurethane will only increase, solidifying the role of these rollers in enhancing productivity and operational efficiency. Investing in high-quality polyurethane rollers ensures that companies can maintain their competitive edge in today's fast-paced market.

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025