impact roller for sale

Impact Rollers for Sale A Comprehensive Guide

In industries ranging from construction to manufacturing, impact rollers play a crucial role in ensuring efficiency and productivity. As essential equipment for many applications, including material handling and transportation, the demand for high-quality impact rollers is ever-increasing. If you are in the market for impact rollers for sale, understanding their features, benefits, and considerations can help you make an informed decision.

What are Impact Rollers?

Impact rollers are specialized components designed to absorb shock and reduce the impact of materials during transportation on various surfaces, such as conveyor belts. They are typically used in systems that handle bulk materials, like gravel, sand, or coal, and serve to minimize wear and tear on the equipment while ensuring a smooth flow of materials.

Features of Quality Impact Rollers

When searching for impact rollers for sale, it is essential to look for specific features that guarantee performance and durability

1. Material Composition High-quality rollers are often made from robust materials such as steel or high-strength polymers that withstand heavy loads and harsh working conditions.

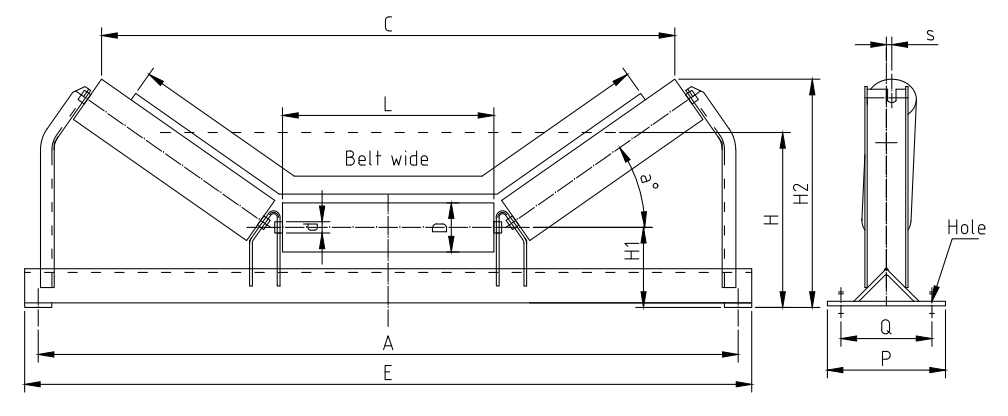

2. Design and Engineering Impact rollers should be designed with a focus on shock absorption. A well-engineered roller can significantly reduce vibrations, enhancing equipment lifespan and operational efficiency.

3. Sealed Bearings To prevent contamination from dust and debris, look for rollers with sealed bearings, which require less maintenance and improve the overall reliability of the roller.

4. Customization Options Many manufacturers offer customizable impact rollers that can be tailored to meet specific operational needs, including size, load-bearing capacity, and additional features like rubber coverings for extra impact absorption.

Benefits of Using Impact Rollers

Investing in quality impact rollers comes with several advantages

impact roller for sale

1. Enhanced Durability With superior shock absorption capabilities, impact rollers prolong the life of both the roller itself and the equipment they are used with.

2. Improved Material Flow The right rollers facilitate smoother transportation processes, reducing the risk of material spillage and operational downtime.

3. Reduced Maintenance Costs Durability and effective shock absorption translate to less frequent repairs and maintenance, which can significantly lower operational costs in the long run.

4. Safety Impact rollers contribute to creating a safer working environment by minimizing slips and falls, as they help maintain stable material flow.

Considerations When Buying Impact Rollers

Before making a purchase, consider the following aspects

1. Application Requirements Assess the specific needs of your operation to determine the type and specifications of the impact rollers that will best suit your requirements.

2. Manufacturer Reputation Research manufacturers to ensure you are buying from a reputable source known for quality and reliability.

3. Cost vs. Quality While it may be tempting to go for the cheapest option, investing in high-quality impact rollers can yield better long-term savings and efficiency.

4. Warranty and Support Check if the manufacturer offers a warranty or post-sale support. A solid warranty can provide peace of mind regarding your investment.

Conclusion

Purchasing impact rollers for sale is a crucial step in optimizing material handling processes within various industries. By understanding the features, benefits, and considerations associated with impact rollers, you can make informed choices that enhance your operational efficiency and reduce long-term costs. Whether you are upgrading your existing systems or starting new projects, quality impact rollers can play an indispensable role in your success.

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025