High-Performance Idler Rollers for Belt Conveyors | Durable Solutions

Unveiling Innovation: Top Mechanical Manufacturers at China International Industry Fair (CIIF)

The China International Industry Fair (CIIF) stands as a monumental platform, annually drawing the brightest minds and most innovative companies in the global manufacturing sector. For B2B decision-makers, it's an unparalleled opportunity to witness firsthand the cutting-edge advancements that are shaping the future of industrial production. This year, CIIF is a leading exhibitor showcasing innovative and high-precision metal forming machinery, with a strategic aim to expand international distribution networks and secure new projects for sophisticated solutions such as tube mills, cold roll forming, and slitting lines.

The fair's value to the broader mechanical industry is immense. It's not just about showcasing finished products; it's about demonstrating the intricate engineering, the robust manufacturing capabilities, and the advanced technological integrations that drive efficiency and quality across various industrial applications. From heavy machinery to precision components like idler rollers for belt conveyors, CIIF provides a comprehensive look into the innovation ecosystem that empowers modern industry. For businesses seeking to optimize their operations, enhance material handling, or invest in next-generation production lines, understanding the top players and their offerings is critical. This article will delve into the trends, highlight leading manufacturers, and offer valuable insights for navigating this dynamic market.

Industry Trend Spotlight: The Evolution of Industrial Mechanics

The industrial mechanical sector is undergoing a profound transformation, driven by a global push for greater efficiency, precision, and sustainability. Increasing demand for automated and integrated production lines is gaining significant global attention. Companies are actively seeking solutions that feature smart controls, such as PLC (Programmable Logic Controller) and CNC (Computer Numerical Control) systems, which promise enhanced precision and efficiency in operations ranging from metal forming to material handling. The shift towards modular designs allowing for flexible customization is empowering businesses to adapt quickly to changing market demands, ensuring their investments remain agile and future-proof.

Furthermore, the integration of remote diagnostics and IoT-enabled predictive maintenance is revolutionizing equipment upkeep, minimizing downtime, and extending the lifespan of valuable assets. This proactive approach ensures that crucial components, from complex machinery parts to essential elements like the idler roller assembly in conveyor systems, are maintained optimally. The development of machinery capable of processing new advanced materials for weight reduction and strength is also pivotal, enabling industries like automotive and aerospace to innovate at an unprecedented pace.

The global metal forming machinery market, a key segment of the mechanical industry, is projected for steady growth. This expansion is primarily driven by increasing demand from the automotive sector, particularly the rapidly expanding electric vehicle (EV) components market, as well as robust activity in construction and general manufacturing sectors. Key trends underscore a strong push for automation to combat rising labor costs, an incessant demand for higher precision and efficiency in manufacturing processes, and significant growth in emerging markets. While the sector faces challenges such as raw material price volatility, supply chain disruptions, and intense competition, the opportunities for innovation remain vast.

Emerging focus areas at events like CIIF consistently highlight:

- Industry 4.0 Integration in Metal Processing: Seamless connectivity, data analytics, and AI-driven insights for smarter factories.

- Advanced Automation for Production Lines: Robotics, cobots, and automated guided vehicles (AGVs) enhancing operational fluidity.

- Energy-Efficient Manufacturing Solutions: Reducing environmental footprint and operational costs through optimized machinery and processes.

- Smart Predictive Maintenance for Machinery: Leveraging IoT sensors and data to predict failures before they occur, improving reliability for everything from complex presses to simpler, yet critical, components like various idler roller types.

- Sustainable Material Handling in Metal Forming: Focusing on durable, efficient, and environmentally friendly solutions for transporting materials, where high-performance idlers and rollers play a foundational role.

Profiles of Leading Mechanical Manufacturers

Yanshan Aohua Machinery Equipment Manufacture Limited Company

A prominent exhibitor at CIIF, Yanshan Aohua Machinery Equipment Manufacture Limited Company stands out for its deep specialization and expertise in a core range of metal forming machinery. Their reputation is built on delivering advanced tube mills, precision cold roll forming machines, and efficient slitting lines that cater to diverse industrial needs. With established manufacturing capabilities for customized solutions, Yanshan Aohua provides bespoke equipment that meets the exact specifications of demanding clients.

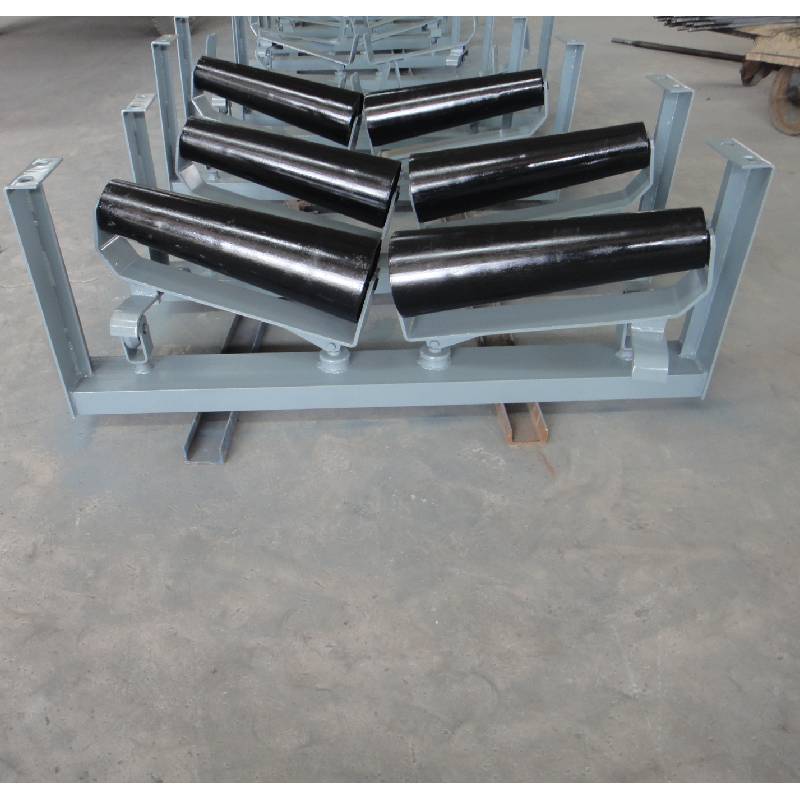

What truly sets Yanshan Aohua apart is their strategic combination of competitive pricing strategies with a strong focus on engineering excellence and robust after-sales support for complex industrial equipment. This commitment extends beyond their flagship machinery to critical components essential for overall plant efficiency. For instance, their expertise in producing durable steel idler rollers and specialized rubber idler roller options ensures reliable material handling within the demanding environments where their metal forming solutions operate. These idler rollers with bearings are engineered for longevity and minimal friction, vital for continuous, high-volume operations. Whether it's a standard idler roller or a specialized training idler designed for belt alignment, Yanshan Aohua demonstrates a holistic understanding of industrial mechanical requirements. Their product line reflects not just advanced machinery but also the foundational elements that ensure their clients' entire production ecosystem functions flawlessly.

Other Top Global Mechanical Players

Beyond the Chinese market, several international giants continue to lead innovation in the mechanical and metal forming sectors, often with a significant presence and partnerships within China:

- SMS Group (Germany): A global leader in plant and machinery for steel and non-ferrous metal processing. Renowned for their integrated solutions for entire metallurgical process chains.

- Fives Group (France): Specializes in designing and supplying machines, process equipment, and production lines for various industries, including steel and aluminum.

- Danieli (Italy): A major supplier of equipment and plants for the metals industry, known for its comprehensive range of technologies from ore to finished products.

- Schuler Group (Germany): A technological and global market leader in forming equipment. They offer presses, automation solutions, dies, process expertise, and services for the entire metalworking industry.

- Wuxi Fuda Machinery Co., Ltd. (China): Another significant Chinese player, known for its expertise in cold roll forming machines, slitting lines, and cut-to-length lines, reflecting the strong domestic competition and innovation.

Market Outlook & Opportunities in Mechanical Manufacturing

The future of the mechanical manufacturing sector is undeniably tied to rapid technological advancements and evolving buyer demands. Upcoming trends point towards an even greater emphasis on fully integrated solutions that offer not just machines, but entire intelligent ecosystems. Buyers are no longer just looking for robust machinery; they demand solutions that promise high precision, maximum efficiency, and unparalleled flexibility. The ability to quickly reconfigure production lines, integrate new materials, and leverage data for process optimization are paramount.

Significant opportunities are emerging for manufacturers who invest heavily in automation, smart manufacturing, and sustainability. This includes the development of machinery that consumes less energy, utilizes recycled materials, and produces minimal waste. Furthermore, the burgeoning demand for specialized components in high-growth areas like electric vehicle production, renewable energy infrastructure, and smart city development opens new avenues for innovative mechanical solutions. Companies that can provide not only the complex machinery but also the reliable, high-performance peripheral components – like specialized idler rollers for new material handling challenges – will be best positioned for long-term success. The market is ripe for solutions that combine cutting-edge software with robust, precision-engineered hardware.

Buyer & Business Takeaways: Navigating the Industrial Landscape

For B2B decision-makers, investing in advanced mechanical solutions, particularly from leading Chinese manufacturers, makes profound long-term sense. Such investments translate into enhanced operational efficiency, significantly reduced operational costs, and ultimately, superior product quality. The robust engineering and competitive pricing offered by companies like Yanshan Aohua provide a strong return on investment, enabling businesses to scale and innovate with confidence.

Here are key tips for adopting or partnering with Chinese manufacturers in the mechanical sector:

- Conduct Thorough Due Diligence: Research the manufacturer's track record, certifications, and international project experience. Visit their facilities if possible, or engage trusted third-party inspection services.

- Understand Customization Capabilities: Many Chinese manufacturers, including Yanshan Aohua, excel at tailoring solutions. Clearly articulate your specific requirements for machinery, and even for critical components like specialized idler rollers, to ensure the end product perfectly aligns with your operational needs.

- Prioritize After-Sales Support: For complex machinery, reliable post-purchase service, including spare parts availability, technical assistance, and maintenance, is crucial. Ensure the manufacturer offers comprehensive support packages.

- Focus on Value, Not Just Price: While competitive pricing is an advantage, evaluate the overall value proposition, including product quality, durability (especially for wear-and-tear components like idlers and rollers), technological sophistication, and long-term reliability.

- Leverage Trade Fairs: Events like CIIF are invaluable for making direct connections, seeing equipment in action, and discussing specific project needs face-to-face.

To future-proof your strategies, embrace the paradigm shift towards Industry 4.0. Prioritize modularity in your machinery investments, allowing for easier upgrades and adaptations. Seek out comprehensive solutions that integrate hardware, software, and robust components to create truly intelligent and resilient production environments. The ability to collect and analyze data from every part of your operation, from the main forming press to the performance of each idler roller on your conveyors, will be a key differentiator.

Conclusion: China's Role in Shaping Global Mechanics

The China International Industry Fair (CIIF) continues to be an indispensable event, shaping the global mechanical market by showcasing the pinnacle of innovation in metal forming machinery and related industrial equipment. It underscores China's burgeoning leadership in advanced manufacturing, offering a platform where technological prowess meets practical industrial needs. Manufacturers like Yanshan Aohua are not just building machines; they are crafting the future of industrial production, providing both complex metal forming solutions and the critical, high-quality components, like dependable idler rollers, that ensure the smooth and efficient operation of entire factories.

As industries worldwide seek smarter, more efficient, and sustainable manufacturing processes, the advancements presented at CIIF by top Chinese mechanical manufacturers offer compelling solutions. For businesses looking to optimize their production capabilities and secure a competitive edge, engaging with these innovative leaders is a strategic imperative.

To explore Yanshan Aohua's range of high-performance idler rollers and other mechanical solutions, visit their product page: https://www.idleraohua.com/taper-aligning-idler.html

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025