Mar . 07, 2025 07:27

Back to list

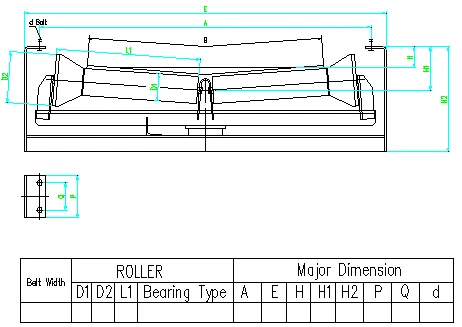

Customized Roller

Heavy-duty conveyor belt rollers serve as the backbone of bulk material handling in industries ranging from mining to manufacturing. Their importance in maintaining the efficiency and reliability of conveyor systems cannot be overstated. With decades of evolution, these components have become indispensable, owing to their inherent ability to support heavy loads and extend the lifespan of conveyor systems.

Trustworthiness in the realm of heavy-duty conveyor belt rollers can be quantified through factors like the longevity of product life cycles and the consistency of performance across various industrial conditions. Reputable manufacturers offer warranties that attest to the durability of their rollers, providing end-users with the assurance of value and reliability. Moreover, third-party certifications and compliance with international safety and quality standards bolster the trust clients place in these products. From a practical perspective, the installation of heavy-duty conveyor rollers involves a strategic selection process. Factors such as load weight, conveyor speed, and environmental conditions must be considered to ensure optimal performance. An experienced installer will also analyze factors such as roller spacing and alignment to prevent premature failure, demonstrating the intricate relationship between expertise and equipment reliability. Ultimately, heavy-duty conveyor belt rollers represent a blend of cutting-edge technology and practical know-how. They embody the principles of Experience, Expertise, Authoritativeness, and Trustworthiness, delivering unmatched reliability and efficiency. Whether in industries that demand robustness, like mining and steel production, or those requiring precision, such as automotive manufacturing, these rollers are engineered to handle the most demanding conditions while preserving the integrity of the conveyor systems they support. This advanced knowledge and commitment to quality elevate the role of heavy-duty conveyor belt rollers from mere components to pivotal elements that propel whole industries forward. As technology continues to advance, their evolution will remain aligned with the emerging needs of industries, setting new benchmarks in durability and performance.

Trustworthiness in the realm of heavy-duty conveyor belt rollers can be quantified through factors like the longevity of product life cycles and the consistency of performance across various industrial conditions. Reputable manufacturers offer warranties that attest to the durability of their rollers, providing end-users with the assurance of value and reliability. Moreover, third-party certifications and compliance with international safety and quality standards bolster the trust clients place in these products. From a practical perspective, the installation of heavy-duty conveyor rollers involves a strategic selection process. Factors such as load weight, conveyor speed, and environmental conditions must be considered to ensure optimal performance. An experienced installer will also analyze factors such as roller spacing and alignment to prevent premature failure, demonstrating the intricate relationship between expertise and equipment reliability. Ultimately, heavy-duty conveyor belt rollers represent a blend of cutting-edge technology and practical know-how. They embody the principles of Experience, Expertise, Authoritativeness, and Trustworthiness, delivering unmatched reliability and efficiency. Whether in industries that demand robustness, like mining and steel production, or those requiring precision, such as automotive manufacturing, these rollers are engineered to handle the most demanding conditions while preserving the integrity of the conveyor systems they support. This advanced knowledge and commitment to quality elevate the role of heavy-duty conveyor belt rollers from mere components to pivotal elements that propel whole industries forward. As technology continues to advance, their evolution will remain aligned with the emerging needs of industries, setting new benchmarks in durability and performance.

Next:

Latest news

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025

OUR PRODUCTS