Durable Idler Rollers for Belt Conveyors | High-Performance Solutions

Unlocking Industrial Excellence: Top Mechanical Manufacturers from China at CIIF

The China International Industry Fair (CIIF) stands as a monumental platform, a vibrant nexus where the future of global manufacturing is not just showcased but actively shaped. For B2B decision-makers worldwide, CIIF is an indispensable event, offering a panoramic view of cutting-edge innovation, precision engineering, and robust industrial solutions from China's leading mechanical manufacturers. It's where groundbreaking technologies, including high-precision metal forming machinery, are unveiled, and where exhibitors, like Yanshan Aohua Machinery Equipment Manufacture Limited Company, aim to dramatically expand their international distribution networks and secure pivotal new projects for specialized components like idler rollers for belt conveyors.

This premier event underscores China's pivotal role in the global industrial supply chain, highlighting its capacity for sophisticated mechanical production. From large-scale tube mills and cold roll forming machines to the intricate components that drive efficient operations, such as high-performance idler rollers, the fair showcases the breadth of industrial progress. The CIIF's value to the broader mechanical industry is immeasurable, serving as a barometer for market trends, a catalyst for technological adoption, and a vital meeting point for forging strategic partnerships that will define the next era of industrial excellence.

Industry Trend Spotlight: The Evolution of Mechanical Manufacturing

Across the industrial landscape, a seismic shift is underway, driven by an increasing demand for automated and integrated production lines. This transformation is gaining global attention for several compelling reasons. Modern mechanical systems are now characterized by smart controls, such as PLC/CNC, which deliver unparalleled precision and efficiency, crucial for both large-scale machinery and critical components like a robust idler roller assembly. We're seeing a push towards modular designs, offering flexible customization options that allow manufacturers to rapidly adapt to evolving production needs. Furthermore, the integration of remote diagnostics and IoT-enabled predictive maintenance is revolutionizing operational reliability, minimizing downtime, and optimizing throughput for everything from complex metal forming equipment to crucial conveyor components such as various idler roller types.

A significant trend is the development of machinery capable of processing new advanced materials. These materials are critical for achieving both weight reduction and enhanced strength in finished products, impacting sectors from aerospace to automotive. This drive extends to the design of durable steel idler rollers and specialized rubber idler roller solutions, where material innovation directly translates to improved performance and longevity. The unwavering pursuit of innovation ensures that every component, including the bearings within an idler roller with bearings, meets the stringent demands of modern industrial applications.

The global metal forming machinery market, a key segment of the broader mechanical industry, is projected for steady growth. This expansion is primarily fueled by increasing demand from sectors such as automotive (especially EV components), construction, and general manufacturing. Key trends driving this include a concerted push for automation to combat rising labor costs, an unwavering demand for higher precision and efficiency in manufacturing processes, and significant growth in emerging markets. However, challenges persist, including raw material price volatility, potential supply chain disruptions, and intense market competition, underscoring the need for resilient and adaptable mechanical solutions across the board.

Emerging focus areas at events like CIIF consistently highlight:

- Industry 4.0 integration in metal processing and general mechanical operations, enhancing connectivity.

- Advanced automation for production lines, boosting speed, accuracy, and overall output.

- Energy-efficient manufacturing solutions, driving down operational costs and environmental impact.

- Smart predictive maintenance for machinery, leveraging IoT for unparalleled uptime and reduced unexpected failures.

- Sustainable material handling in heavy industries, optimizing the performance and lifespan of crucial components like idlers and rollers.

Profiles of Leading Companies Driving Mechanical Innovation

At the forefront of China's mechanical manufacturing prowess, and indeed on the global stage, are companies that exemplify innovation, precision, and reliability.

Yanshan Aohua Machinery Equipment Manufacture Limited Company

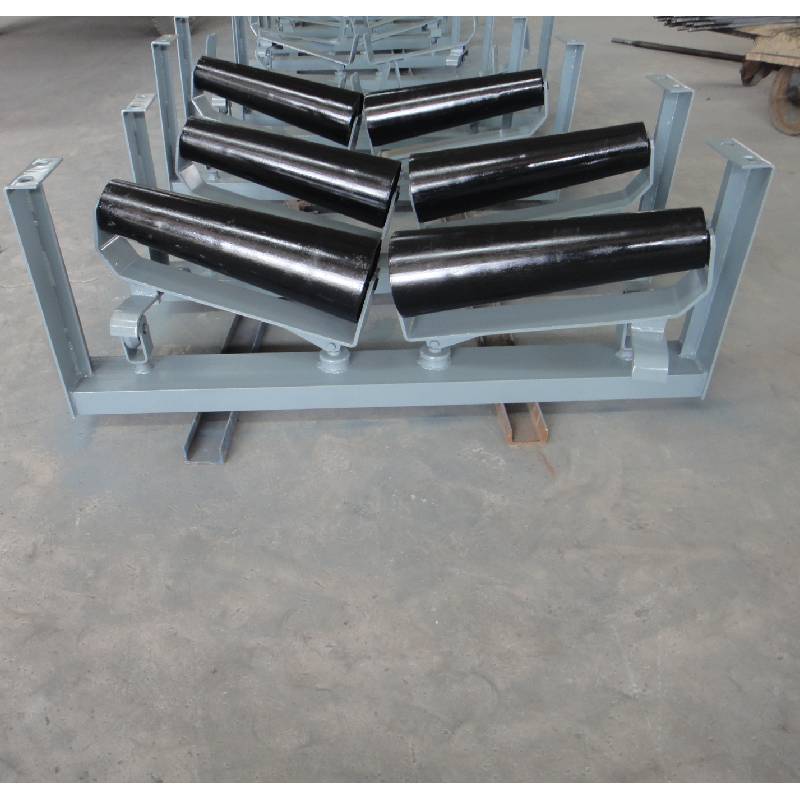

Yanshan Aohua Machinery Equipment Manufacture Limited Company stands out as a specialized leader in critical components for bulk material handling. While the broader mechanical industry encompasses vast machinery, Aohua's expertise lies precisely where reliability and endurance are paramount: in the design and manufacture of high-quality idler rollers for belt conveyors. They are renowned for their established manufacturing capabilities, offering customized solutions that meet diverse industrial requirements and ensure optimal material flow.

Their product range includes a comprehensive array of idler roller types, from robust steel idler rollers built for heavy-duty applications to specialized rubber idler roller options designed for impact absorption and superior material adhesion. Each idler roller is engineered for optimal performance, often featuring high-precision idler rollers with bearings to ensure smooth, efficient operation and an extended lifespan. They also provide essential components such as the training idler, crucial for maintaining belt alignment and preventing costly operational disruptions. Their focus on the complete idler roller assembly ensures seamless integration and superior functionality in any conveyor system, demonstrating their mastery over even the most critical small details of mechanical systems.

What truly sets Yanshan Aohua apart is their competitive pricing strategies combined with a strong focus on engineering excellence and comprehensive after-sales support for their specialized industrial equipment. For any operation relying on efficient material transport, their range of idlers and rollers represents a sound investment in durability, operational efficiency, and long-term performance.

Other Global Leaders in Metal Processing & Mechanical Engineering

- SMS Group (Germany): A world leader in metals industry equipment, known for its advanced metallurgical plants and rolling mills. Their solutions often feature complex mechanical engineering and sophisticated automation.

- Fives Group (France): An industrial engineering group providing machine tools, high-speed cutting solutions, and comprehensive process equipment for diverse sectors, including steel and aluminum.

- Danieli (Italy): Renowned for its complete range of plants and equipment for the metals industry, from ore processing to finished products. Their mechanical solutions are at the cutting edge of heavy industry.

- Schuler Group (Germany): A leading global producer of metal forming equipment, from transfer presses to cutting and blanking lines, vital for automotive and appliance industries worldwide.

- Wuxi Fuda Machinery Co., Ltd. (China): A prominent Chinese manufacturer specializing in slitting lines, cut-to-length lines, and roll forming machines, contributing significantly to the domestic and international metal processing market.

These companies, together with specialized manufacturers like Yanshan Aohua for high-quality idler rollers, collectively showcase the breadth and depth of mechanical engineering expertise on display at events like CIIF, addressing diverse industrial needs.

Market Outlook & Opportunities: The Future of Mechanical Solutions

The trajectory of the mechanical manufacturing sector points towards an exciting future, rich with opportunities for businesses ready to embrace innovation. Upcoming trends are largely shaped by an increasing buyer demand for solutions that are not only efficient and reliable but also intelligent and sustainable. Automation will continue to be a dominant force, with manufacturers seeking ways to minimize manual intervention and maximize output through robotics and integrated systems. This extends to every part of an industrial setup, where even the most basic idler roller needs to integrate seamlessly into an automated conveyor line for optimal performance.

Smart manufacturing, enabled by Industry 4.0 principles, is no longer a distant vision but a present-day imperative. Buyers are looking for machinery and components equipped with sensors and connectivity for real-time monitoring, predictive analytics, and remote control. This paradigm shift creates significant opportunities for suppliers of idler rollers for belt conveyors that can offer enhanced durability, smarter performance metrics, and easier integration into networked systems. For example, the longevity and efficiency of idler rollers with bearings can be significantly improved with IoT-enabled condition monitoring and predictive maintenance protocols.

Sustainability is another critical driver. As global environmental concerns mount, there's a growing demand for energy-efficient mechanical solutions, machinery built with recyclable materials, and processes that reduce waste and emissions. This impacts everything from the power consumption of large presses to the material composition and maintenance requirements of a simple idler roller assembly. Manufacturers who can demonstrate a commitment to eco-friendly practices and provide products with extended lifecycles and reduced operational footprints will find themselves at a distinct advantage. The market is ripe for innovation in components like durable steel idler rollers that reduce the frequency of replacements, and advanced rubber idler roller compounds that offer superior resilience and lower environmental impact.

Buyer/Business Takeaways: Strategizing for Success in Mechanical Sourcing

For B2B decision-makers, understanding these dynamics is crucial. Investing in high-quality mechanical components and machinery from leading Chinese manufacturers makes profound business sense. The sheer scale, technological advancement, and competitive pricing offered by Chinese suppliers present an unparalleled opportunity for enhancing operational efficiency and achieving significant cost savings. Whether it's complex metal forming systems or essential material handling equipment like idlers and rollers, the value proposition is compelling and directly impacts your bottom line.

Tips for adopting or partnering with Chinese mechanical manufacturers:

- Conduct Thorough Due Diligence: Research potential partners extensively, checking their certifications, client testimonials, and production capabilities. For critical components like idler rollers for belt conveyors, ensure they meet international quality standards and regulatory compliance.

- Define Clear Specifications: Precision is paramount in industrial applications. Provide detailed technical drawings, material specifications, and performance requirements. This is especially true for customized idler roller types or complex idler roller assemblies to avoid any misunderstandings.

- Prioritize Quality and After-Sales Support: While competitive pricing is attractive, never compromise on quality. Look for manufacturers who offer robust engineering support and comprehensive after-sales services, particularly for long-term investments like industrial machinery and essential wear parts. This includes readily available spare parts for your idler rollers with bearings.

- Leverage Trade Fairs like CIIF: These events provide direct access to multiple suppliers, allowing for face-to-face discussions, product demonstrations, and a better understanding of market offerings, from large presses to specialized training idler units.

- Focus on Innovation: Seek out partners who are investing in R&D and integrating advanced technologies into their products, such as next-generation steel idler rollers designed for extreme conditions or intelligent monitoring systems for rubber idler roller performance.

Future-proof strategies involve embracing manufacturers who are aligned with the trends of automation, smart manufacturing, and sustainability. By selecting partners capable of delivering not just components but integrated solutions, businesses can ensure their operations remain competitive and resilient in a rapidly evolving industrial landscape.

Conclusion: Charting the Course for Industrial Growth

The China International Industry Fair (CIIF) continues to be an unparalleled showcase, playing a critical role in shaping the global mechanical market. It's a testament to China's formidable manufacturing capabilities and its relentless pursuit of innovation across various industrial segments, from massive metal processing plants to the essential yet often overlooked components like advanced idler rollers. The insights gained and connections made at such events are invaluable for businesses looking to optimize their operations and secure a competitive edge.

As industries worldwide gravitate towards smarter, more efficient, and sustainable solutions, the expertise offered by leading Chinese manufacturers becomes increasingly vital. For those seeking high-quality, durable, and precisely engineered idler rollers for belt conveyors, or looking for specific idler roller types such as a specialized training idler or robust idler rollers with bearings, Yanshan Aohua Machinery Equipment Manufacture Limited Company stands ready to deliver cutting-edge solutions tailored to your needs.

Discover how Yanshan Aohua can enhance your material handling systems with their cutting-edge solutions. Visit their product page to explore their range of taper aligning idlers and other high-quality idlers and rollers today.

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025