Durable Idler Rollers for Belt Conveyors | All Types, High Efficiency

The Crucial Role of Idler Rollers in Modern Material Handling

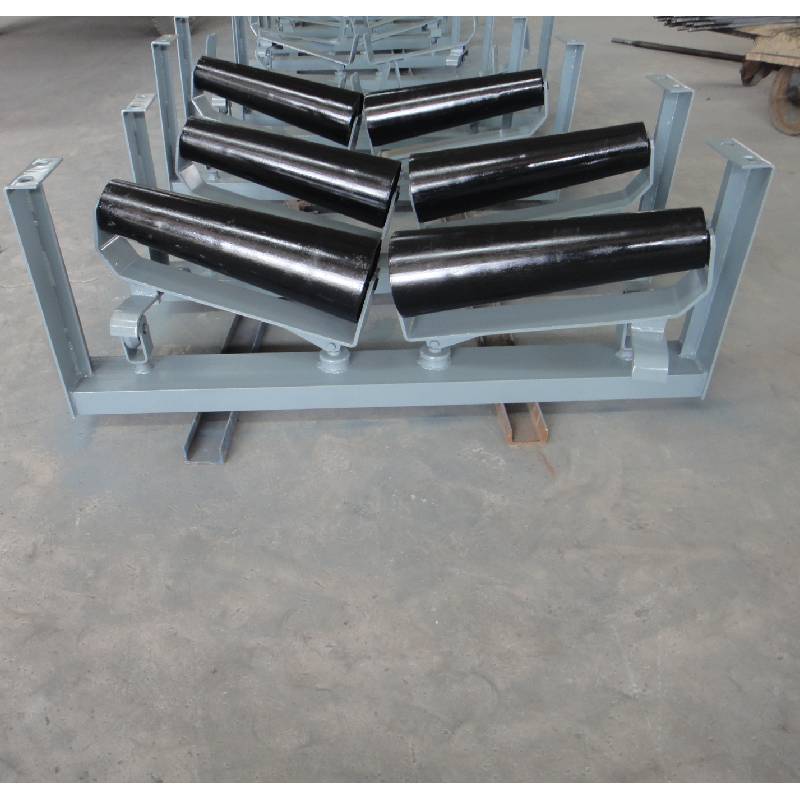

In the vast landscape of industrial material handling, conveyor systems stand as the backbone, facilitating the efficient transport of bulk materials across diverse sectors. At the heart of these robust systems are the idler rollers for belt conveyors, components critical for supporting the conveyor belt and the conveyed material, while minimizing friction and ensuring smooth, reliable operation. These unsung heroes prevent belt sag, guide its path, and contribute significantly to the overall system's efficiency and longevity. From mining and aggregates to power generation and port logistics, the performance of these rollers directly impacts productivity, energy consumption, and maintenance costs. Understanding their design, manufacturing, and application is paramount for any B2B decision-maker focused on optimizing operational throughput and reducing total cost of ownership in their bulk material handling operations.

Beyond mere support, modern idler rollers for belt conveyors are engineered to address specific operational challenges. For instance, specialized training idler units are designed to prevent belt misalignment, a common issue that can lead to material spillage and premature belt wear. The selection of the right idler roller assembly is a strategic decision, influenced by factors such as material characteristics, environmental conditions, and desired service life. Manufacturers are continuously innovating, introducing advanced materials and designs to enhance durability, reduce noise, and lower power consumption, aligning with the industry's drive towards more sustainable and efficient solutions.

Manufacturing Precision: Crafting Superior Idler Rollers

The production of high-performance idler roller components is a testament to precision engineering and stringent quality control. The journey typically begins with the selection of premium materials, primarily high-grade carbon steel or specialized alloys for steel idler rollers, chosen for their exceptional strength-to-weight ratio and resistance to wear. For demanding applications or those requiring impact absorption, a rubber idler roller variant, often with a steel core, is utilized, providing excellent cushioning properties. The manufacturing process involves several critical stages, each meticulously controlled to ensure product integrity and performance.

Key manufacturing processes include high-precision CNC machining for bearing housings and shafts, ensuring tight tolerances for optimal idler rollers with bearings performance. Tube forming and welding are executed with advanced techniques to guarantee concentricity and structural integrity. Surface treatments, such as powder coating or hot-dip galvanizing, are applied to enhance corrosion resistance, particularly for rollers destined for harsh environments. Throughout the process, adherence to international standards like ISO 9001 and ANSI B105.1 is paramount. Rigorous quality checks, including static and dynamic balancing tests, axial load testing, and seal effectiveness verification, are performed on every batch to ensure a consistent service life and reliability. These comprehensive measures ensure that each idler roller delivers optimal performance in its intended application, contributing to reduced operational downtime and extended conveyor system lifespan in industries such as petrochemicals, metallurgy, and water treatment, where durability and efficiency are non-negotiable.

Technical Specifications and Performance Benchmarks

Selecting the appropriate idler rollers for belt conveyors requires a thorough understanding of their technical specifications and performance benchmarks. These parameters directly influence the roller's suitability for specific applications, its durability, and overall operational efficiency. Key specifications include roller diameter, shell thickness, shaft diameter, bearing type, and seal design. For instance, larger roller diameters often translate to lower rotational speeds for a given belt speed, reducing bearing wear and extending roller life. Shell thickness is crucial for impact resistance and structural integrity, especially when handling heavy or abrasive materials.

The bearing type in idler rollers with bearings significantly impacts frictional resistance and load capacity. Deep groove ball bearings are common due to their versatility and moderate load capabilities, while specialized sealed bearings are preferred for dusty or wet environments to prevent contamination. Seal design, such as labyrinth seals, plays a critical role in protecting the bearings from ingress of dust, moisture, and other contaminants, thereby prolonging the life of the idler roller assembly. Manufacturers also provide data on dynamic and static load ratings, rotational resistance, and expected service life under various operating conditions, all of which are essential for engineering a reliable and efficient conveyor system.

Typical Idler Rollers for Belt Conveyors - Parameter Overview

| Parameter | Typical Range/Value | Significance |

|---|---|---|

| Roller Diameter (D) | 89mm - 219mm | Affects rotational speed, bearing life, and belt contact. |

| Shell Thickness | 4mm - 10mm | Impact resistance and structural integrity. |

| Shaft Diameter (d) | 20mm - 40mm | Load bearing capacity and rigidity. |

| Bearing Type | 6204-2RS to 6310-2RS (Deep Groove Ball) | Frictional resistance, load capacity, and lifespan. |

| Seal Design | Multi-labyrinth seal, Rubber contact seal | Protection against dust, moisture, and contaminants. |

| Material | Q235 Carbon Steel, ASTM A36, Stainless Steel | Strength, wear resistance, and corrosion resistance. |

| Operating Temperature | -20°C to +80°C | Suitability for various environmental conditions. |

| Radial Run-out | ≤ 0.5mm | Indicates manufacturing precision and smooth operation. |

Application Scenarios and Strategic Advantages of Idler Rollers

The versatility of idler rollers for belt conveyors makes them indispensable across a wide spectrum of heavy industries. In the mining sector, robust steel idler rollers and impact rubber idler roller variants are crucial for handling abrasive ores and absorbing the shock of material loading. For power plants, particularly those relying on coal, specialized idlers and rollers must withstand high temperatures and dusty environments while maintaining low rotational resistance for energy efficiency. In port operations, where high throughput and continuous operation are critical, heavy-duty troughing and return idlers ensure stable belt operation, even with irregular loads, leading to minimal downtime and maximized material transfer rates.

Beyond supporting the belt, certain idler roller types offer specific strategic advantages. Taper aligning idlers, such as the Taper Aligning Idler, are designed to automatically correct belt misalignment, preventing costly spillage and belt edge damage. This proactive alignment reduces wear on the belt and other conveyor components, significantly extending their lifespan. The choice of idler roller assembly can also impact energy consumption; well-designed rollers with low friction bearings and effective seals reduce the power required to drive the conveyor, contributing to substantial energy savings over time. Furthermore, corrosion-resistant idlers are vital in environments exposed to moisture, chemicals, or saltwater, such as in fertilizer plants or coastal terminals, preventing premature failure and ensuring long-term operational integrity. These targeted solutions underscore the importance of selecting the right idlers and rollers to achieve specific operational goals, from enhanced safety to improved sustainability and reduced operational costs.

Choosing Your Partner: Manufacturer Comparison and Custom Solutions

When investing in idler rollers for belt conveyors, selecting the right manufacturer is as crucial as selecting the right product. A reputable manufacturer offers not only a comprehensive range of standard and specialized idler roller types but also possesses the expertise to provide tailored solutions. Key differentiators include a proven track record, adherence to international quality certifications (e.g., ISO 9001, CEMA standards), and extensive experience in diverse industry applications. Manufacturers who prioritize research and development, continuously introducing innovations like improved sealing systems for idler rollers with bearings or advanced materials for rubber idler roller applications, demonstrate a commitment to long-term performance and customer satisfaction. An example of this commitment is our own specialization in providing highly durable and efficient idler roller assembly units, designed for challenging industrial environments and backed by extensive real-world performance data.

Beyond standard offerings, the ability to provide custom solutions is a significant advantage. This includes designing idlers and rollers to meet unique conveyor dimensions, specialized load requirements, extreme environmental conditions, or specific integration needs. Our engineering team, leveraging years of experience, collaborates closely with clients to develop bespoke steel idler rollers and other roller solutions, ensuring optimal fit and maximum efficiency for their unique bulk material handling challenges. This consultative approach, combined with robust manufacturing capabilities, allows us to deliver solutions that not only meet but exceed performance expectations, translating into tangible operational benefits for our partners.

Real-World Impact: Case Studies and Client Successes

The true measure of quality for idler rollers for belt conveyors lies in their performance in real-world applications and the feedback from satisfied clients. For instance, in a large-scale iron ore mining operation, the replacement of standard idlers with our specially designed steel idler rollers featuring enhanced bearing protection resulted in a documented 25% reduction in unplanned downtime related to roller failures over a 12-month period. This directly translated into increased operational throughput and significant cost savings. Another compelling case involved a major petrochemical facility experiencing frequent belt mistracking due to corrosive conditions. By implementing our Taper Aligning Idler, specifically engineered with advanced corrosion-resistant coatings, the client achieved consistent belt alignment, virtually eliminating spillage and extending the lifespan of their costly conveyor belts by over 30%.

Our commitment extends beyond product delivery to comprehensive after-sales support and long-term partnerships. A client in the aggregate industry reported a remarkable 15% reduction in overall conveyor system energy consumption after upgrading to our low-friction idler rollers with bearings. This improvement was attributed to our precise manufacturing tolerances and advanced seal designs, which minimize rotational resistance. These examples underscore our dedication to providing idlers and rollers that not only meet rigorous technical specifications but also deliver tangible economic and operational benefits, reinforcing our position as a trusted partner in the bulk material handling industry.

Ensuring Reliability: Trustworthiness & Support

Frequently Asked Questions (FAQ)

-

Q: What factors influence the lifespan of idler rollers for belt conveyors?

A: Key factors include bearing quality, seal design effectiveness, shell material and thickness, environmental conditions (dust, moisture, temperature), and proper installation and maintenance practices. Our rollers are designed with multi-labyrinth seals and high-quality bearings to maximize longevity, even in challenging environments.

-

Q: How do I choose the correct idler roller type for my application?

A: Selection depends on material handled (abrasive, heavy, sticky), belt width, belt speed, environmental conditions, and specific operational needs (e.g., impact absorption, belt alignment). We offer various idler roller types, including troughing, return, impact, and training idlers. Our technical experts are available to provide tailored recommendations based on your unique requirements.

-

Q: Are your steel idler rollers suitable for corrosive environments?

A: Yes, we offer steel idler rollers with specialized surface treatments like hot-dip galvanizing or epoxy powder coating, along with stainless steel options, designed to resist corrosion in harsh and chemically aggressive environments such as those found in chemical processing plants or coastal port facilities.

Delivery Timelines and Warranty Information

We understand the critical need for timely delivery in industrial operations. Our standard manufacturing and delivery cycles for common idler roller assembly configurations typically range from 2 to 4 weeks, depending on order volume and customization requirements. For urgent projects, expedited options may be available. All our idlers and rollers come with a comprehensive warranty of 12 to 24 months from the date of installation or 18 to 30 months from the date of shipment, whichever comes first. This warranty covers defects in material and workmanship, underscoring our confidence in the durability and quality of our products and providing peace of mind to our clients regarding their investment in idler rollers with bearings.

Dedicated Customer Support

Our commitment to customer satisfaction extends throughout the product lifecycle. We provide comprehensive technical support, from initial consultation and product selection to installation guidance and troubleshooting. Our team of experienced engineers and support staff is readily available to address any inquiries, ensuring that your idler rollers for belt conveyors perform optimally and contribute effectively to your operational goals. We also offer maintenance recommendations and spare parts availability to ensure minimal disruption and maximum uptime for your conveyor systems.

References

- Belt Conveyors for Bulk Materials. Conveyor Equipment Manufacturers Association (CEMA), 7th Edition.

- ISO 9001:2015 Quality Management Systems – Requirements. International Organization for Standardization.

- Standards for Idlers for Belt Conveyors. American National Standards Institute (ANSI) / CEMA B105.1.

- The Engineering of Conveyor Systems. International Journal of Mining and Mineral Engineering.

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025