Jan . 16, 2025 03:04

Back to list

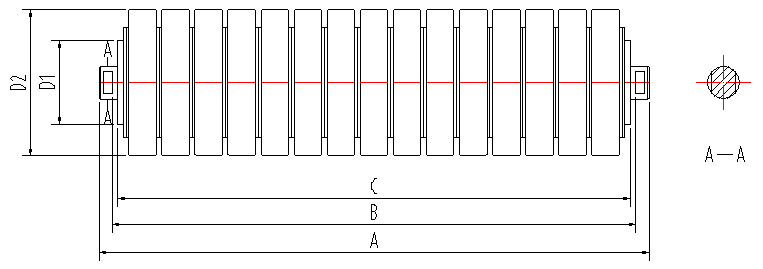

v belt drive pulley

Drive pulley shafts are pivotal components in various industrial machines and equipment, serving as the bridge that transmits power from a motor to a pulley system. With intricate mechanical interactions, selecting the right drive pulley shaft involves a blend of experience, expertise, and a keen understanding of engineering principles. Here we delve into the essential aspects of drive pulley shafts that ensure optimal performance, longevity, and reliability.

Trustworthiness in the manufacture and supply of drive pulley shafts is demonstrated through rigorous testing and quality assurance processes. Reputable manufacturers implement comprehensive testing procedures such as non-destructive testing (NDT) and fatigue analysis to verify the integrity and longevity of each shaft. Ensuring that every product batch meets stringent quality criteria builds confidence among users and positions the supplier as a reliable partner in operational success. For industries relying on conveyors, fans, pumps, and other equipment, choosing the right drive pulley shaft can lead to significant improvements in efficiency and downtime reduction. Moreover, partnering with providers who offer expert installation, maintenance advice, and responsive customer support ensures that any unforeseen challenges are swiftly addressed, maintaining seamless operations. In conclusion, the drive pulley shaft is more than just a mechanical component; it is a critical element that affects the performance and reliability of entire systems. Leveraging experience and expertise in material selection, design, and engineering can lead to enhanced performance and longevity. With a focus on authoritativeness and trustworthiness, businesses can ensure that their selection of drive pulley shafts translates into tangible operational benefits, solidifying their standing in competitive industrial landscapes.

Trustworthiness in the manufacture and supply of drive pulley shafts is demonstrated through rigorous testing and quality assurance processes. Reputable manufacturers implement comprehensive testing procedures such as non-destructive testing (NDT) and fatigue analysis to verify the integrity and longevity of each shaft. Ensuring that every product batch meets stringent quality criteria builds confidence among users and positions the supplier as a reliable partner in operational success. For industries relying on conveyors, fans, pumps, and other equipment, choosing the right drive pulley shaft can lead to significant improvements in efficiency and downtime reduction. Moreover, partnering with providers who offer expert installation, maintenance advice, and responsive customer support ensures that any unforeseen challenges are swiftly addressed, maintaining seamless operations. In conclusion, the drive pulley shaft is more than just a mechanical component; it is a critical element that affects the performance and reliability of entire systems. Leveraging experience and expertise in material selection, design, and engineering can lead to enhanced performance and longevity. With a focus on authoritativeness and trustworthiness, businesses can ensure that their selection of drive pulley shafts translates into tangible operational benefits, solidifying their standing in competitive industrial landscapes.

Next:

Latest news

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025

OUR PRODUCTS