High-Quality Carbon Steel Rollers for Industrial Applications

The Significance of Carbon Steel Rollers in Industrial Applications

Carbon steel rollers are essential components in various industrial processes, serving a multitude of functions across different sectors. Known for their excellent mechanical properties and cost-effectiveness, these rollers have become a staple in manufacturing, construction, and transportation industries.

Carbon steel, an alloy of iron and carbon, boasts a variety of properties that enhance its performance. The carbon content in the steel typically ranges from 0.05% to 2.0%, and it plays a critical role in determining the hardness and tensile strength of the material. In applications that require high durability and resistance to wear, carbon steel rollers are often the preferred choice. They provide superior strength compared to other materials, making them ideal for heavy-duty tasks.

One of the primary applications of carbon steel rollers is in the manufacturing of conveyors. These rollers facilitate the smooth movement of materials along conveyor belts, allowing for efficient handling during production processes. Various industries, including mining, food processing, and logistics, utilize carbon steel rollers to optimize their operations. Their ability to withstand harsh environments and heavy loads contributes significantly to productivity and operational efficiency.

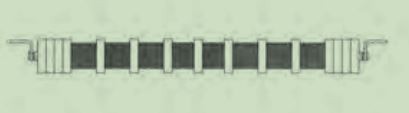

carbon steel roller

In addition to conveyors, carbon steel rollers are also integral in the fabrication of machinery and equipment. They are used in machines for shaping, cutting, and rolling metal sheets and other materials. The robustness of carbon steel ensures that these rollers can endure significant stress and maintain precision in their operations. This capability is crucial in industries where the quality and accuracy of the final products are paramount.

Moreover, carbon steel rollers are employed in construction applications, particularly in scaffolding and formwork systems. Their strength and durability make them ideal for supporting structures during the building process. By ensuring the stability of scaffolding, carbon steel rollers contribute to the safety of construction workers and the overall integrity of the construction site.

Maintenance of carbon steel rollers is crucial to ensure their longevity and performance. Regular inspection and lubrication can prevent excessive wear and tear, thereby extending their service life. Additionally, proper handling during installation and operation can minimize the risk of damage, further enhancing their reliability.

In summary, carbon steel rollers play a vital role in various industrial applications, providing durability, strength, and efficiency. Their versatility makes them suitable for a wide range of tasks, from material handling in conveyor systems to supporting construction projects. As industries continue to evolve and demand higher performance materials, carbon steel rollers will remain an indispensable component in ensuring operational excellence.

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025