Mar . 07, 2025 06:21

Back to list

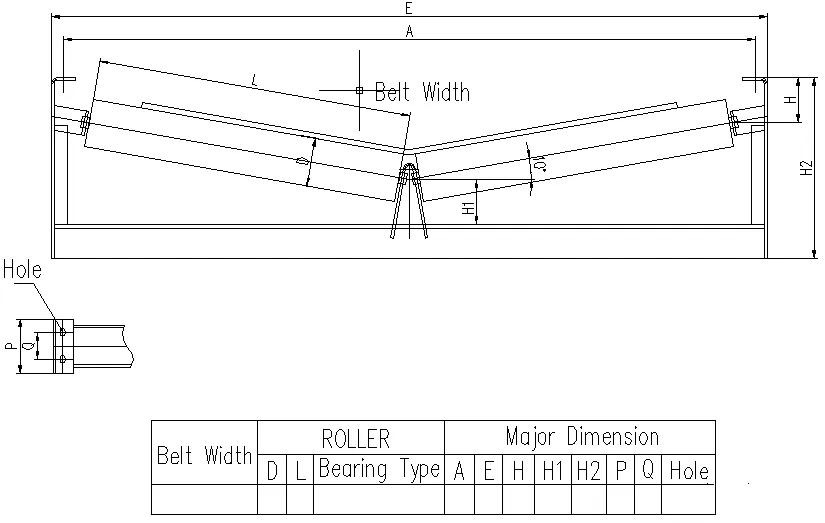

Guide Roller

In the world of industrial handling and conveyor systems, belt guide rollers stand as silent sentinels ensuring smooth, efficient, and safe operations. These crucial components play a pivotal role in various sectors, ranging from manufacturing to logistics, each demanding precision and reliability to maintain operational efficiency. This article delves into the intricacies of belt guide rollers — exploring their integral functions, design innovations, and the benefits they bring to industries worldwide.

An essential aspect of belt guide roller systems is their maintenance, which ensures longevity and consistent functionality. Scheduled inspections complemented by comprehensive maintenance protocols can preempt potential issues, safeguarding an operation’s uptime. Companies must foster a proactive maintenance culture, training operators to recognize early signs of wear and facilitating swift interventions that prevent major breakdowns. Case studies demonstrate the exemplary impact of strategically implemented belt guide rollers. For instance, in a case involving a major logistics company, the integration of advanced guide rollers resulted in a 30% increase in throughput efficiency and a significant decrease in maintenance costs. Such tangible outcomes underscore the value of investing in top-tier components and highlight the expertise of manufacturers who set standards in roller technology. When it comes to industry best practices, collaboration with certified suppliers is paramount to ensure the acquisition of dependable belt guide rollers. Suppliers with a proven track record of compliance with international standards bolster the trust in their products, offering reassurance through warranties and post-sale support. Their standing influence and reliability reinforce the trustworthiness factor, which is indispensable in product selection. The role of belt guide rollers cannot be overstated. They are instrumental in enhancing operational efficiency, safeguarding against unscheduled downtimes, and driving cost-effective solutions. As industries evolve, the demand for refined guide roller systems continues to surge, pushing manufacturers to innovate and supply products that meet tomorrow’s challenges. In conclusion, belt guide rollers are not just components—they are pivotal players in the seamless functioning of conveyor systems. Their contribution to the efficiency, safety, and sustainability of industrial operations is incontrovertible, anchoring their position as essential investments for industry players seeking robust and reliable solutions. By embracing innovation and prioritizing maintenance, businesses can harness the full potential of these vital components, ensuring perpetual growth and success.

An essential aspect of belt guide roller systems is their maintenance, which ensures longevity and consistent functionality. Scheduled inspections complemented by comprehensive maintenance protocols can preempt potential issues, safeguarding an operation’s uptime. Companies must foster a proactive maintenance culture, training operators to recognize early signs of wear and facilitating swift interventions that prevent major breakdowns. Case studies demonstrate the exemplary impact of strategically implemented belt guide rollers. For instance, in a case involving a major logistics company, the integration of advanced guide rollers resulted in a 30% increase in throughput efficiency and a significant decrease in maintenance costs. Such tangible outcomes underscore the value of investing in top-tier components and highlight the expertise of manufacturers who set standards in roller technology. When it comes to industry best practices, collaboration with certified suppliers is paramount to ensure the acquisition of dependable belt guide rollers. Suppliers with a proven track record of compliance with international standards bolster the trust in their products, offering reassurance through warranties and post-sale support. Their standing influence and reliability reinforce the trustworthiness factor, which is indispensable in product selection. The role of belt guide rollers cannot be overstated. They are instrumental in enhancing operational efficiency, safeguarding against unscheduled downtimes, and driving cost-effective solutions. As industries evolve, the demand for refined guide roller systems continues to surge, pushing manufacturers to innovate and supply products that meet tomorrow’s challenges. In conclusion, belt guide rollers are not just components—they are pivotal players in the seamless functioning of conveyor systems. Their contribution to the efficiency, safety, and sustainability of industrial operations is incontrovertible, anchoring their position as essential investments for industry players seeking robust and reliable solutions. By embracing innovation and prioritizing maintenance, businesses can harness the full potential of these vital components, ensuring perpetual growth and success.

Next:

Latest news

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025

OUR PRODUCTS