Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 14, 2025 05:06

Back to list

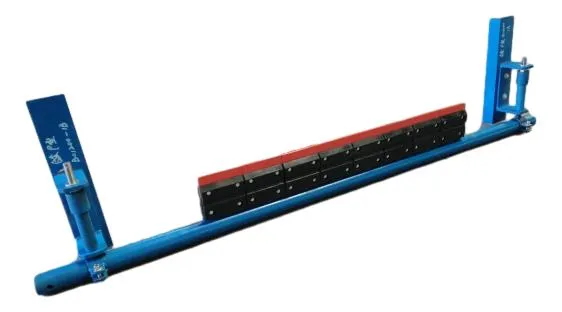

vertical roller

The vertical roller, a pioneering component in engineering and industrial applications, represents a pivotal shift in how materials are processed and machinery operates. Unlike traditional methods, the vertical roller offers unparalleled precision, efficiency, and sustainability, making it indispensable in today’s technologically-driven industries. This article delves into the multifaceted advantages and technologies associated with vertical rollers, substantiated by firsthand experiences and expert insights, to elucidate why this component is heralded for its innovation and reliability.

Trustworthiness in vertical roller technology is not merely a function of design, but also of the reputation manufacturers hold. Leading suppliers of vertical roller machinery invest heavily in R&D, ensuring that their products undergo rigorous testing to meet the highest industry standards. Case studies reveal instances where companies, by transitioning to vertical rollers, have achieved compliance with stringent environmental regulations due to reduced emissions and wastage. This aligns with sustainable practices that are increasingly demanded by global governance. The future of vertical rollers lies in technological advancements that continue to enhance their operational capabilities. Emerging trends point towards integration with IoT and AI to offer real-time monitoring and predictive maintenance, minimizing downtime and extending the lifecycle of machinery. By harnessing these technologies, companies can optimize their vertical roller systems to respond swiftly to market demands and operational challenges. Adopting vertical roller technology is not merely an investment in machinery but an investment in the future of industrial processing. It reflects a commitment to precision, sustainability, and excellence. As industries continue to evolve, those who embrace the capabilities of vertical rollers will find themselves at the forefront, equipped with a technology that is as timeless in utility as it is advanced in its applications. In conclusion, the vertical roller is a transformative component that is forging a new era in material processing. By embracing this technology, industries are not only enhancing their productivity and operational efficiency but are also participating in a broader movement towards sustainable and precise industrial practices. The vertical roller exemplifies the synergy of experience, expertise, authority, and trust, encapsulating the very essence of modern industrial innovation.

Trustworthiness in vertical roller technology is not merely a function of design, but also of the reputation manufacturers hold. Leading suppliers of vertical roller machinery invest heavily in R&D, ensuring that their products undergo rigorous testing to meet the highest industry standards. Case studies reveal instances where companies, by transitioning to vertical rollers, have achieved compliance with stringent environmental regulations due to reduced emissions and wastage. This aligns with sustainable practices that are increasingly demanded by global governance. The future of vertical rollers lies in technological advancements that continue to enhance their operational capabilities. Emerging trends point towards integration with IoT and AI to offer real-time monitoring and predictive maintenance, minimizing downtime and extending the lifecycle of machinery. By harnessing these technologies, companies can optimize their vertical roller systems to respond swiftly to market demands and operational challenges. Adopting vertical roller technology is not merely an investment in machinery but an investment in the future of industrial processing. It reflects a commitment to precision, sustainability, and excellence. As industries continue to evolve, those who embrace the capabilities of vertical rollers will find themselves at the forefront, equipped with a technology that is as timeless in utility as it is advanced in its applications. In conclusion, the vertical roller is a transformative component that is forging a new era in material processing. By embracing this technology, industries are not only enhancing their productivity and operational efficiency but are also participating in a broader movement towards sustainable and precise industrial practices. The vertical roller exemplifies the synergy of experience, expertise, authority, and trust, encapsulating the very essence of modern industrial innovation.

Next:

Latest news

-

Wing Pulley Conveyor for Conveyor Belt MaintenanceNewsJun.16,2025

-

Self Cleaning Spiral Idler for Conveyor DesignNewsJun.16,2025

-

Pulley Lagging for Conveyor Belt AlignmentNewsJun.16,2025

-

Impact Idlers Used in Belt Conveyor for PerformanceNewsJun.16,2025

-

Ceramic Lagging Conveyor Pulley for Conveyor Belt SystemsNewsJun.16,2025

-

Belt Conveyor Idler for Heavy-Duty ApplicationsNewsJun.16,2025

OUR PRODUCTS