Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu troughing rolls

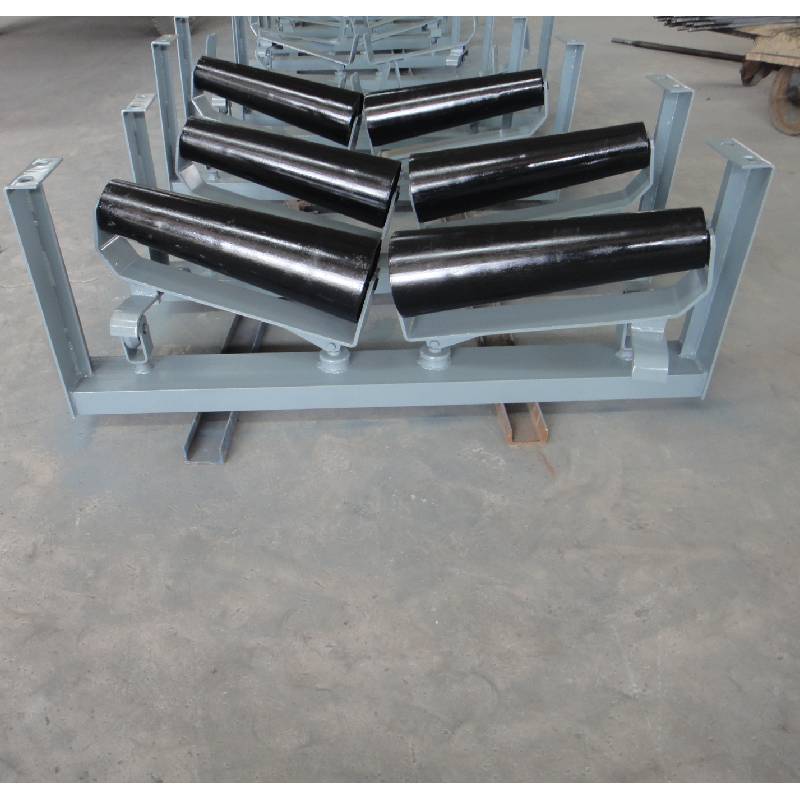

Understanding Troughing Rolls in Conveyor Systems

Troughing rolls are a fundamental component in the design and operation of conveyor systems, particularly in bulk material handling operations. These specialized rollers play a crucial role in ensuring efficiency, durability, and safety in various industries, including mining, agriculture, and logistics.

What are Troughing Rolls?

Troughing rolls are designed to support and shape the conveyor belt as it moves materials from one point to another. The name “troughing” refers to the rollers being positioned in a way that creates a trough-like shape, typically with three or more rollers forming the bottom and sides, which helps contain the material on the belt. This design is intrinsic to managing the transportation of materials effectively, minimizing spillage, and ensuring smooth movement.

Types of Troughing Rolls

There are several types of troughing rolls available, each catering to specific applications and material types. The most common configurations are the three-roll trough, which is standard for general applications, and the five-roll trough, which is often used for larger or heavier loads. The angle of the trough can vary as well, typically being set at 20, 30, or 45 degrees, depending on the material being transported and the conveyor’s operational requirements.

Benefits of Troughing Rolls

1. Material Containment The trough design keeps materials securely on the belt, reducing the risk of spillage and ensuring a cleaner workspace. This is particularly vital in industries where product loss can lead to significant economic ramifications.

2. Enhanced Stability Troughing rolls provide better support to the conveyor belt, enhancing its stability during operation. This is essential when transporting uneven loads, as it minimizes wear and tear on both the belt and the rollers themselves.

troughing rolls

3. Reduced Wear and Tear With the correct installation and maintenance, troughing rolls can minimize friction and wear on the conveyor system. This is critical for extending the lifespan of the belts and components, ultimately leading to lower maintenance costs.

4. Orientation and Alignment Troughing rolls help maintain the alignment of the belt as it moves, which is crucial for both safety and efficiency. Proper orientation prevents the belt from drifting off-course or becoming misaligned, which could result in operational disruptions.

5. Versatility Troughing rolls can be used in a wide range of applications, accommodating various materials, from grains to rocks to packaged goods. This versatility makes them a preferred choice across multiple industries.

Challenges and Considerations

While troughing rolls offer numerous advantages, certain challenges must be addressed. Overloading the conveyor can lead to premature failure of the rolls or the belt itself. Regular maintenance checks are essential to ensuring the system operates efficiently and to prevent potential downtime caused by mechanical failure.

Additionally, the choice of material for the troughing rolls must align with the specific type of material being transported. For instance, using rubberized or coated rollers can help reduce noise and provide additional grip for slippery materials.

Conclusion

Troughing rolls are an integral part of modern conveyor systems, facilitating the efficient and safe transport of bulk materials in various industries. Their design not only aids in material containment and stabilization but also enhances the overall productivity of operations. Understanding the importance of troughing rolls and their appropriate application can significantly improve the reliability and efficiency of conveyor systems, thereby contributing to the success of industrial operations. As industries continue to evolve, the role of troughing rolls will remain pivotal, adapting to new material handling challenges and advancements in technology.

-

Taper Centering Idler Set for Conveyor SystemsNewsJun.25,2025

-

Small Idler Rollers for Industrial ConveyorsNewsJun.25,2025

-

Guide Training Idler Set for Conveyor MaintenanceNewsJun.25,2025

-

Friction Offset Idler Set for Industrial UseNewsJun.25,2025

-

Double-Center-Roller Idler AlignmentNewsJun.25,2025

-

Channel Inset Impact Troughing Idler Set for Heavy LoadsNewsJun.25,2025