Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu rollers and idlers

Rollers and Idlers Essential Components in Conveyor Systems

In the realm of industrial machinery and material handling, rollers and idlers play a crucial role in the efficient operation of conveyor systems. These components are integral to the transport of goods across various sectors, including manufacturing, logistics, and mining. Understanding their functions and types can greatly enhance the efficiency of any conveyor operation.

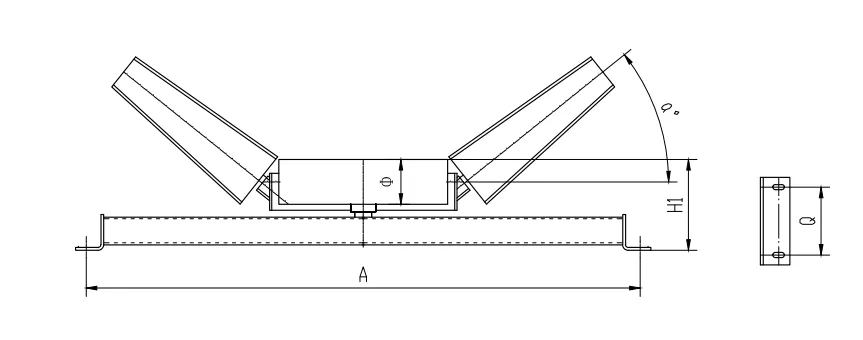

Rollers are cylindrical components that facilitate the movement of materials along the conveyor belt. They are strategically placed at intervals along the conveyor system to support the belt and its load. The primary function of rollers is to reduce friction, allowing materials to move smoothly and efficiently. Available in various designs, such as flat, crowned, or rubber-coated, rollers can be tailored to suit specific operational needs and the type of materials being transported. For instance, crowned rollers are particularly effective at keeping the belt centered, while rubber-coated rollers provide increased grip, particularly for slippery materials.

rollers and idlers

On the other hand, idlers are similar to rollers but serve a slightly different purpose. Idlers are non-powered components that support the weight of the conveyor belt and its load along the return side of the conveyor system. They help maintain the proper tension in the belt, ensuring it remains taut as it moves. Idlers are also essential for minimizing wear and tear on the belt, extending its lifespan, and reducing maintenance costs. Typically, idlers can be categorized into various types, including troughing idlers, which are designed to hold the belt in a concave shape to contain the load, and return idlers, which support the belt as it returns to the loading point.

The selection of appropriate rollers and idlers is critical for optimizing conveyor performance. Factors such as load capacity, speed, environmental conditions, and the nature of the materials being transported must all be considered. Properly installed and maintained rollers and idlers enhance the efficiency of the conveyor system, contributing to overall operational productivity.

In conclusion, rollers and idlers are vital components in the functioning of conveyor systems. Their roles in reducing friction, supporting loads, and maintaining belt tension are essential for the smooth operation of material handling processes. By investing in high-quality rollers and idlers and ensuring their proper maintenance, industries can achieve greater efficiency, reduce downtime, and enhance the longevity of their conveyor systems.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025