Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Advantages of Using Polyurethane Pipe Rollers in Industrial Applications

The Versatility of Polyurethane Pipe Rollers An Essential Tool in Industries

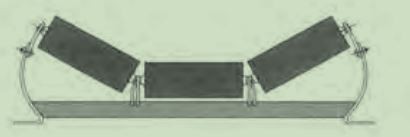

Polyurethane pipe rollers have gained significant traction across various industries due to their unique properties that enhance performance, durability, and efficiency. These specialized rollers are designed to support the movement and installation of pipes, making them indispensable in manufacturing plants, construction sites, and infrastructure development projects.

What are Polyurethane Pipe Rollers?

Polyurethane pipe rollers are cylindrical tools made from polyurethane, a versatile synthetic elastomer known for its resilience and flexibility. Unlike traditional metal or rubber rollers, polyurethane offers greater resistance to abrasion, wear, and tear, making it ideal for heavy-duty applications where the transport of pipes is a constant requirement. These rollers can be customized in various sizes and shapes to accommodate different pipe diameters and weights, catering to a wide array of industries.

Advantages of Polyurethane Pipe Rollers

1. Durability and Strength One of the main advantages of polyurethane pipe rollers is their superior durability. The material can withstand harsh environmental conditions such as extreme temperatures, chemicals, and exposure to UV light. This longevity reduces the need for frequent replacements, contributing to lower operational costs.

2. Reduced Friction The smooth surface of polyurethane rollers minimizes friction, allowing pipes to glide with ease during transportation and installation. This feature is particularly important in industrial settings where time efficiency is crucial.

3. Noise Reduction Polyurethane's ability to dampen vibrations and noise makes it an excellent choice for environments where sound control is necessary. Utilizing these rollers can lead to a quieter workplace, enhancing the overall working conditions for employees.

4. Customizability The versatility of polyurethane allows for the production of rollers in various shapes, sizes, and hardness levels. This means that industries can find or develop rollers that fit their specific needs, whether it’s for large pipelines in oil and gas sectors or smaller fittings in plumbing applications.

polyurethane pipe rollers

5. Safety Features Polyurethane is less likely to chip or break compared to metal rollers, reducing the risk of accidents in a workplace. Furthermore, their lightweight nature makes it easier for workers to handle and maneuver, leading to safer working conditions.

Applications of Polyurethane Pipe Rollers

Polyurethane pipe rollers are utilized in various sectors

- Construction and Civil Engineering During the installation of large pipes for water mains, sewer systems, or drainage, these rollers facilitate movement, reducing wear on both the pipes and the machinery handling them.

- Manufacturing and Production They are commonly found in manufacturing plants where pipes are produced, moved, or assembled. Their ability to support significant weight without deformation ensures efficiency in production lines.

- Oil and Gas In the oil and gas industry, pipe rollers play a critical role in laying pipelines over long distances. Their durability in rugged terrains and resistance to various chemicals make them suitable for such demanding environments.

- Agricultural Irrigation In agriculture, large irrigation pipes need to be installed and maintained regularly. Polyurethane rollers allow for easy handling and movement, facilitating efficient installation processes.

Conclusion

In summary, polyurethane pipe rollers are an essential component in many industries, bringing unparalleled advantages such as durability, reduced friction, and safety. Their ability to be customized for various applications makes them a preferred choice for companies aiming to optimize their operations. As industries continue to evolve and demand high-performance tools, polyurethane pipe rollers will undoubtedly remain at the forefront, adapting to meet the ever-changing needs of the market. Investing in these rollers can significantly enhance productivity and efficiency, proving that the right tools make all the difference in achieving success.

-

Taper Centering Idler Set for Conveyor SystemsNewsJun.25,2025

-

Small Idler Rollers for Industrial ConveyorsNewsJun.25,2025

-

Guide Training Idler Set for Conveyor MaintenanceNewsJun.25,2025

-

Friction Offset Idler Set for Industrial UseNewsJun.25,2025

-

Double-Center-Roller Idler AlignmentNewsJun.25,2025

-

Channel Inset Impact Troughing Idler Set for Heavy LoadsNewsJun.25,2025