Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 13, 2025 14:49

Back to list

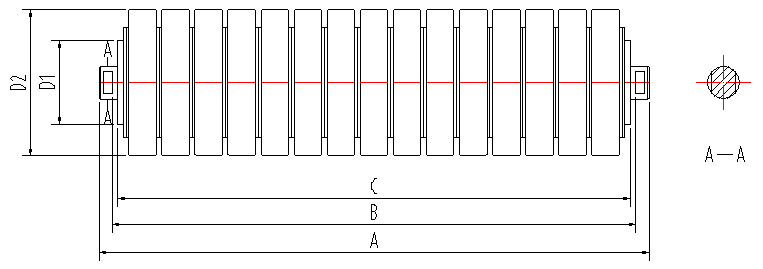

polyurethane idler rollers

Polyurethane drive rollers have emerged as the go-to solution in numerous industrial applications, offering unparalleled performance, durability, and adaptability. As experts in the realm of industrial components, the adoption and integration of polyurethane drive rollers can significantly enhance operational efficiency, product longevity, and cost-effectiveness.

Chemical resistance is a notable characteristic of polyurethane that extends its applicability across industries dealing with corrosive substances. Polyurethane’s resistance to oils, solvents, and other chemicals means that drive rollers composed of this material can withstand the harshest environments. This resilience minimizes the risk of chemical degradation that could compromise roller integrity or performance. In terms of trustworthiness and authoritativeness, polyurethane drive rollers have earned their repute through rigorous testing and adherence to stringent industry standards. They are engineered with precision, ensuring consistency and reliability in performance metrics. Leading manufacturers subject these rollers to comprehensive quality controls, assessing parameters such as tensile strength, elongation, and hardness to guarantee superior performance. Environmental considerations are becoming increasingly vital in product selection. Polyurethane drive rollers stand out for their eco-friendliness since they are commonly manufactured through processes that emit fewer pollutants than traditional rubber or plastic counterparts. Moreover, their longevity reduces waste and the frequency of replacements, which complements sustainability objectives. A key experience shared by industries utilizing polyurethane drive rollers is the dramatic improvement in system efficiency and productivity. Feedback from industry leaders emphasizes not only the cost savings associated with reduced maintenance and downtime but also the operational enhancements through improved material handling and throughput. Companies that have transitioned to polyurethane solutions frequently report a higher return on investment, asserting that the initial cost premium is quickly offset by the ensuing operational benefits. As industrial processes advance, the demand for resilient, efficient, and cost-effective solutions like polyurethane drive rollers continues to grow. These components represent a confluence of innovation and practicality, offering bespoke solutions that cater to the diverse demands of modern industries. Instituting polyurethane drive rollers within your operational setup is likely to yield significant performance enhancements, contributing to smoother processes, extended equipment lifespan, and overall improved industrial outcomes. Hence, the choice of this material extends beyond mere application; it is an investment in the future efficiency and sustainability of industrial operations.

Chemical resistance is a notable characteristic of polyurethane that extends its applicability across industries dealing with corrosive substances. Polyurethane’s resistance to oils, solvents, and other chemicals means that drive rollers composed of this material can withstand the harshest environments. This resilience minimizes the risk of chemical degradation that could compromise roller integrity or performance. In terms of trustworthiness and authoritativeness, polyurethane drive rollers have earned their repute through rigorous testing and adherence to stringent industry standards. They are engineered with precision, ensuring consistency and reliability in performance metrics. Leading manufacturers subject these rollers to comprehensive quality controls, assessing parameters such as tensile strength, elongation, and hardness to guarantee superior performance. Environmental considerations are becoming increasingly vital in product selection. Polyurethane drive rollers stand out for their eco-friendliness since they are commonly manufactured through processes that emit fewer pollutants than traditional rubber or plastic counterparts. Moreover, their longevity reduces waste and the frequency of replacements, which complements sustainability objectives. A key experience shared by industries utilizing polyurethane drive rollers is the dramatic improvement in system efficiency and productivity. Feedback from industry leaders emphasizes not only the cost savings associated with reduced maintenance and downtime but also the operational enhancements through improved material handling and throughput. Companies that have transitioned to polyurethane solutions frequently report a higher return on investment, asserting that the initial cost premium is quickly offset by the ensuing operational benefits. As industrial processes advance, the demand for resilient, efficient, and cost-effective solutions like polyurethane drive rollers continues to grow. These components represent a confluence of innovation and practicality, offering bespoke solutions that cater to the diverse demands of modern industries. Instituting polyurethane drive rollers within your operational setup is likely to yield significant performance enhancements, contributing to smoother processes, extended equipment lifespan, and overall improved industrial outcomes. Hence, the choice of this material extends beyond mere application; it is an investment in the future efficiency and sustainability of industrial operations.

Latest news

-

Wing Pulley Conveyor for Conveyor Belt MaintenanceNewsJun.16,2025

-

Self Cleaning Spiral Idler for Conveyor DesignNewsJun.16,2025

-

Pulley Lagging for Conveyor Belt AlignmentNewsJun.16,2025

-

Impact Idlers Used in Belt Conveyor for PerformanceNewsJun.16,2025

-

Ceramic Lagging Conveyor Pulley for Conveyor Belt SystemsNewsJun.16,2025

-

Belt Conveyor Idler for Heavy-Duty ApplicationsNewsJun.16,2025

OUR PRODUCTS