Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

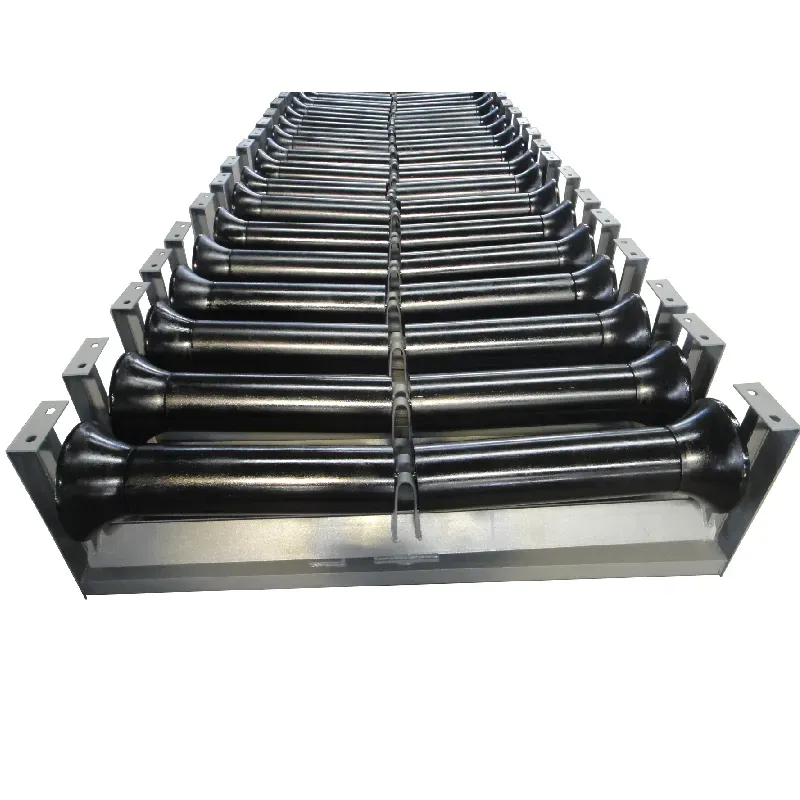

Zulu conveyor side guide

Understanding Conveyor Side Guides Importance and Applications

Conveyors are indispensable components in modern industrial and manufacturing processes. They facilitate the efficient movement of materials and products across various stages of production or assembly. An essential element in ensuring the smooth and effective operation of conveyors is the side guide. Side guides play a crucial role in maintaining product alignment and preventing misalignment during transit along the conveyor system. This article explores the significance, types, and applications of conveyor side guides.

What is a Conveyor Side Guide?

Conveyor side guides are structures attached to the sides of conveyor belts or systems that help to keep items in place as they move along the conveyor. They are instrumental in preventing products from falling off the conveyor or becoming misaligned, which could lead to jams, damaged goods, or inefficient operations. Side guides can be made from various materials, including plastic, rubber, metal, and other durable substances, tailored to withstand the specific demands of the industrial environment.

Importance of Side Guides

1. Improved Product Alignment One of the primary functions of side guides is to keep products aligned as they travel along the conveyor. Misaligned products can lead to significant inefficiencies, increased downtime for adjustments, and potential damage to both the goods and conveyor equipment.

2. Safety Enhancement Side guides help prevent items from falling off the conveyor, which is crucial in maintaining a safe working environment. They help reduce the risk of injuries to personnel and damage to equipment, which could result from unrestrained items.

3. Reduced Maintenance and Downtime By ensuring proper alignment and preventing jams, side guides contribute to reducing the frequency of maintenance and repairs needed for the conveyor system. This leads to minimal downtime, allowing companies to optimize productivity and improve overall operational efficiency.

4. Customization and Flexibility Side guides can be customized to accommodate different product sizes, shapes, and weights. This adaptability ensures that even in dynamic production environments, conveyors can maintain their efficiency regardless of the variations in the items being transported.

Types of Side Guides

Conveyor side guides come in various designs, each suited to specific applications. The two main types include

conveyor side guide

1. Fixed Side Guides These are permanently attached to the conveyor system. They are commonly used in applications where the product dimensions and shapes are consistent, allowing for a stable and reliable guiding solution.

2. Adjustable Side Guides These guides can be repositioned to accommodate different products. Adjustable side guides are ideal for conveyor systems that handle a broad range of products or where the product specifications can frequently change.

Applications of Conveyor Side Guides

Conveyor side guides find applications across various industries, including

- Food and Beverage In this sector, products like bottles, cans, and packaged foods must remain properly aligned to prevent spills and contamination. Side guides ensure the seamless movement of these items.

- Automotive The automotive industry relies on conveyor systems for assembling various components. Side guides help in directing parts accurately through different phases of production.

- Pharmaceuticals In the pharmaceutical field, strict alignment is critical, especially for packaging processes that involve different sized containers. Side guides support the hygienic and organized transport of pharmaceutical products.

- Logistics and Warehousing With the rise of e-commerce, conveyor systems in warehouses and distribution centers help manage inventory efficiently. Side guides play a vital role in preventing items from shifting during transit.

Conclusion

Conveyor side guides may seem like a minor component in the conveyor system, but their role in ensuring efficiency, safety, and productivity is invaluable. By understanding their importance, types, and applications, businesses can better appreciate how these systems contribute to streamlined operations and enhanced industry standards. Investing in the right side guide solutions will ultimately support operational excellence and lead to substantial long-term benefits.

-

Trusted Conveyor Solutions from Leading Conveyor Idler Roller ManufacturersNewsJun.27,2025

-

Reliable Return Idler Solutions for Efficient Belt Conveyor SystemsNewsJun.27,2025

-

Precision Conveyor Accessories for Streamlined Material HandlingNewsJun.27,2025

-

High-Quality Belt Conveyor Idler Solutions for Efficient Material HandlingNewsJun.27,2025

-

High-Performance Belt Conveyor Pulleys for Reliable Material HandlingNewsJun.27,2025

-

Enhancing Material Handling EfficiencyNewsJun.27,2025