Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 07, 2025 05:07

Back to list

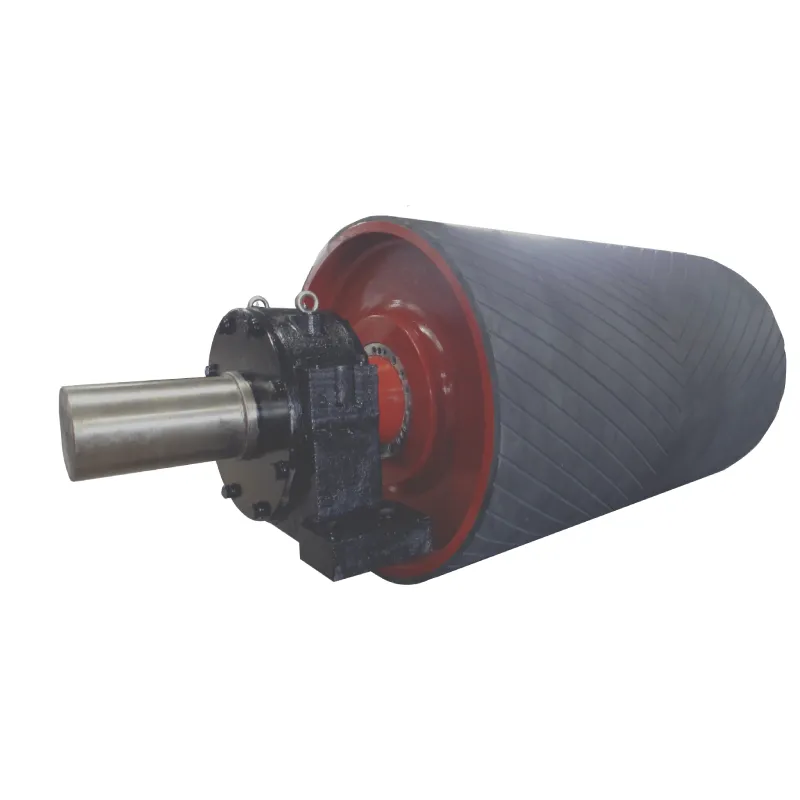

Slagging Pulley(Heavy Duty)

Conveyor belt systems are integral components across numerous industries, driving processes with impeccable efficiency by transporting materials from one point to another. A crucial element in these systems is the pulley, which plays a pivotal role in motion initiation and direction guidance. Understanding the various types of conveyor belt pulleys is essential for optimizing system performance, ensuring reliability, and enhancing safety in operations.

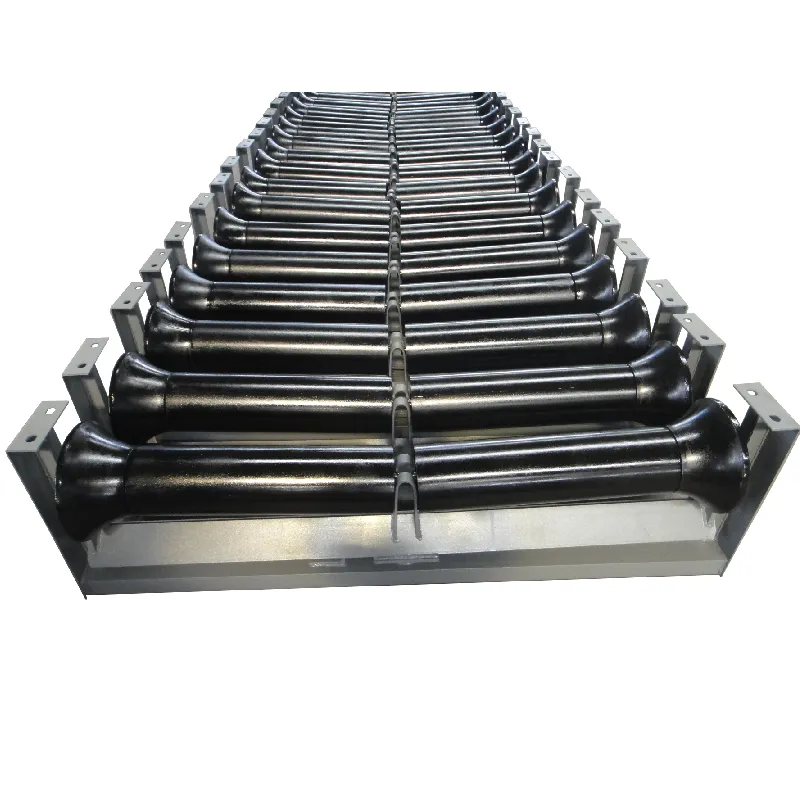

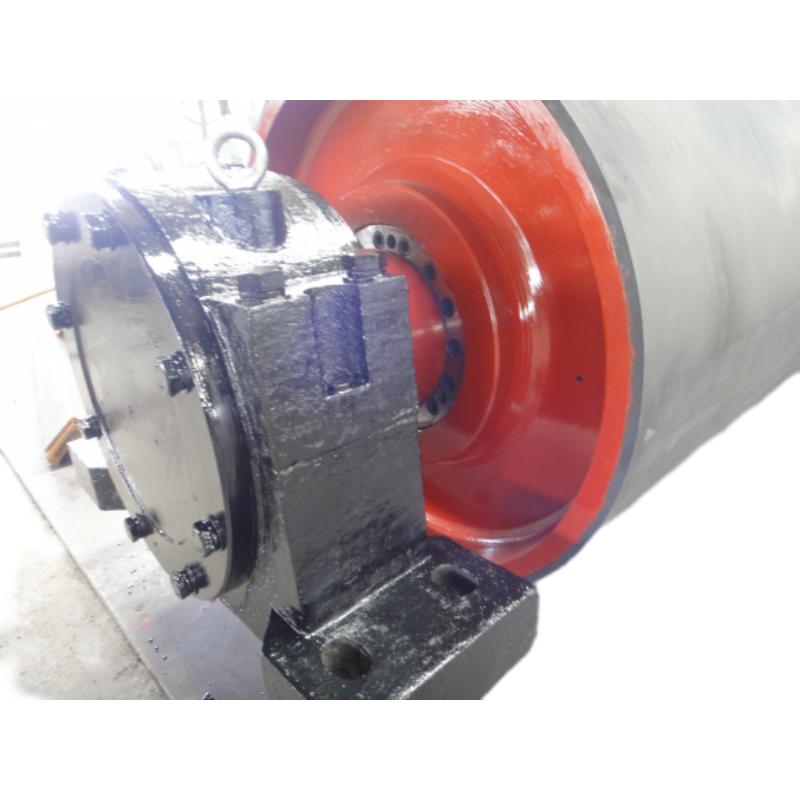

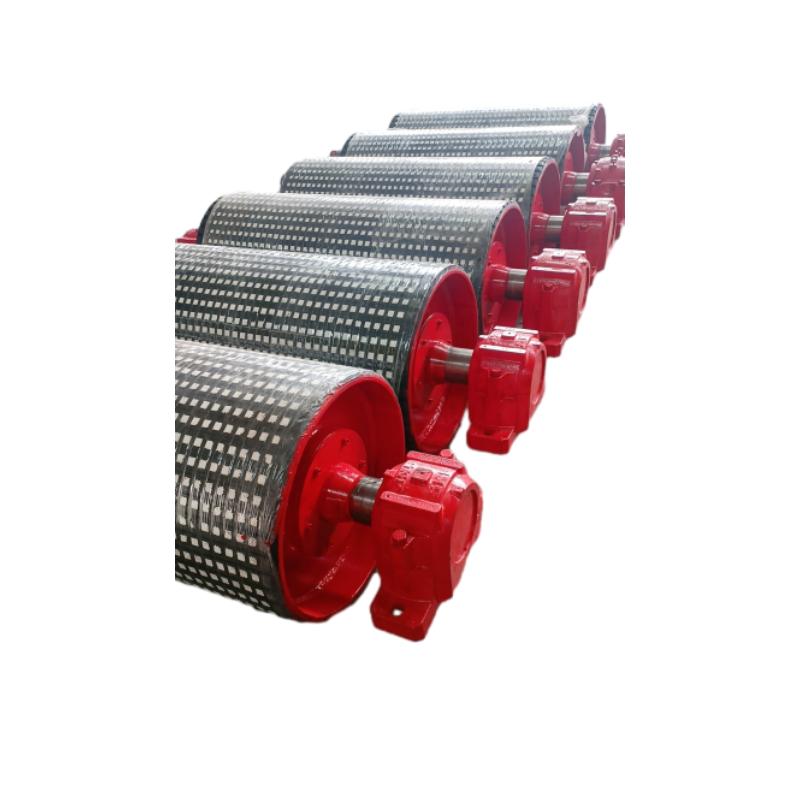

Tensioning in conveyor systems is expertly managed by take-up pulleys. These pulleys are responsible for maintaining the appropriate belt tension, essential for avoiding slippage and ensuring optimal belt tracking. They are typically installed at the belt's tail end in a separate mechanism known as the take-up unit. The precise calibration of take-up pulleys can prevent excessive wear and prolong the lifespan of both the belt and the pulley itself, emphasizing their importance in long-term operational effectiveness. Furthermore, wing pulleys, recognized for their unique design featuring welded wings, are employed in environments with loose materials. These pulleys are engineered to expel materials that build up between the belt and pulley surface, a feature which minimizes risk of damage and reduces clean-up downtime. Their utility in sectors dealing with granular or particulate materials highlights their role in preserving the structural integrity of both the belt and the pulley. For a conveyor system to function reliably, it requires pulleys that are not only appropriate to the operational demands but also constructed with the right materials. Stainless steel pulleys, for instance, deliver superior resistance to corrosion, making them ideal for industries such as food processing and pharmaceuticals where hygiene and durability are paramount. Similarly, pulleys with rubber lagging surface treatments offer enhanced grip, crucial in high-humidity environments or applications involving substantial material loads. Selecting the correct type of conveyor belt pulley is a sophisticated process involving a thorough analysis of operational requirements, environmental conditions, and material types handled by the system. By leveraging expertise in pulley technology, industries can enhance their system's effectiveness, reduce maintenance costs, and ensure seamless operational continuity. In conclusion, the expertise involved in understanding conveyor belt pulley types combines technical know-how, material science, and strategic system design. Prioritizing factors such as load capacity, environmental compatibility, and surface treatment can greatly influence a conveyor system's success. Manufacturers and operators must rely on meticulous engineering and authoritative guidance to select the right pulleys, thereby optimizing performance and safeguarding investments.

Tensioning in conveyor systems is expertly managed by take-up pulleys. These pulleys are responsible for maintaining the appropriate belt tension, essential for avoiding slippage and ensuring optimal belt tracking. They are typically installed at the belt's tail end in a separate mechanism known as the take-up unit. The precise calibration of take-up pulleys can prevent excessive wear and prolong the lifespan of both the belt and the pulley itself, emphasizing their importance in long-term operational effectiveness. Furthermore, wing pulleys, recognized for their unique design featuring welded wings, are employed in environments with loose materials. These pulleys are engineered to expel materials that build up between the belt and pulley surface, a feature which minimizes risk of damage and reduces clean-up downtime. Their utility in sectors dealing with granular or particulate materials highlights their role in preserving the structural integrity of both the belt and the pulley. For a conveyor system to function reliably, it requires pulleys that are not only appropriate to the operational demands but also constructed with the right materials. Stainless steel pulleys, for instance, deliver superior resistance to corrosion, making them ideal for industries such as food processing and pharmaceuticals where hygiene and durability are paramount. Similarly, pulleys with rubber lagging surface treatments offer enhanced grip, crucial in high-humidity environments or applications involving substantial material loads. Selecting the correct type of conveyor belt pulley is a sophisticated process involving a thorough analysis of operational requirements, environmental conditions, and material types handled by the system. By leveraging expertise in pulley technology, industries can enhance their system's effectiveness, reduce maintenance costs, and ensure seamless operational continuity. In conclusion, the expertise involved in understanding conveyor belt pulley types combines technical know-how, material science, and strategic system design. Prioritizing factors such as load capacity, environmental compatibility, and surface treatment can greatly influence a conveyor system's success. Manufacturers and operators must rely on meticulous engineering and authoritative guidance to select the right pulleys, thereby optimizing performance and safeguarding investments.

Latest news

-

Taper Centering Idler Set for Conveyor SystemsNewsJun.25,2025

-

Small Idler Rollers for Industrial ConveyorsNewsJun.25,2025

-

Guide Training Idler Set for Conveyor MaintenanceNewsJun.25,2025

-

Friction Offset Idler Set for Industrial UseNewsJun.25,2025

-

Double-Center-Roller Idler AlignmentNewsJun.25,2025

-

Channel Inset Impact Troughing Idler Set for Heavy LoadsNewsJun.25,2025

OUR PRODUCTS